Tungsten alloy particle spallation target material

A tungsten alloy and spallation target technology, applied in the field of tungsten alloy particle spallation target materials, can solve the problems of unsuitability of pure tungsten, heat dissipation, and insufficient mechanical properties, and achieve the best comprehensive fluidity and heat transfer performance, excellent Effects of mechanical properties and high radiation damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

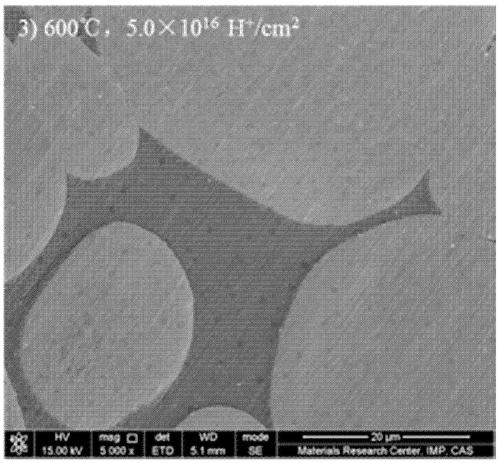

[0019] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

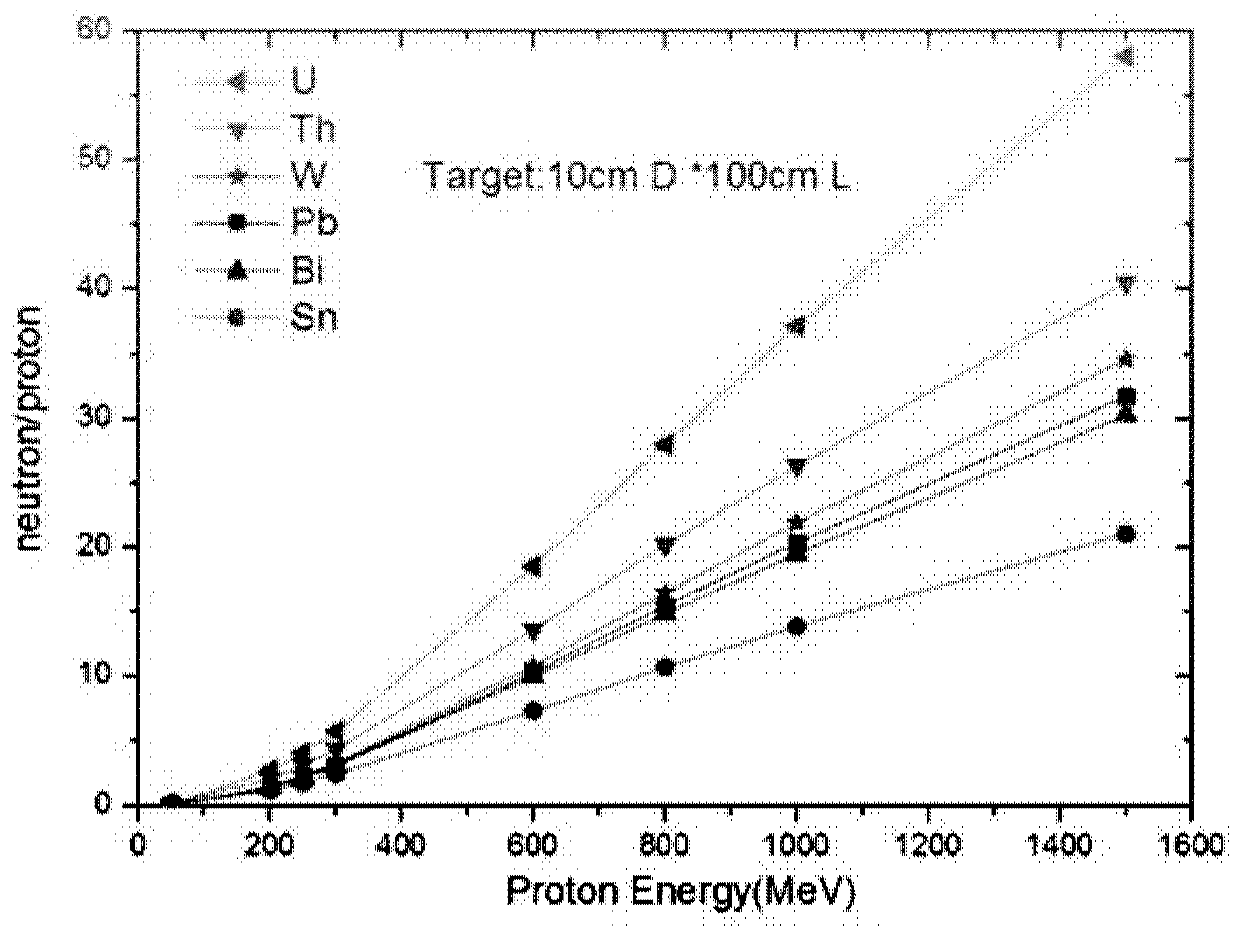

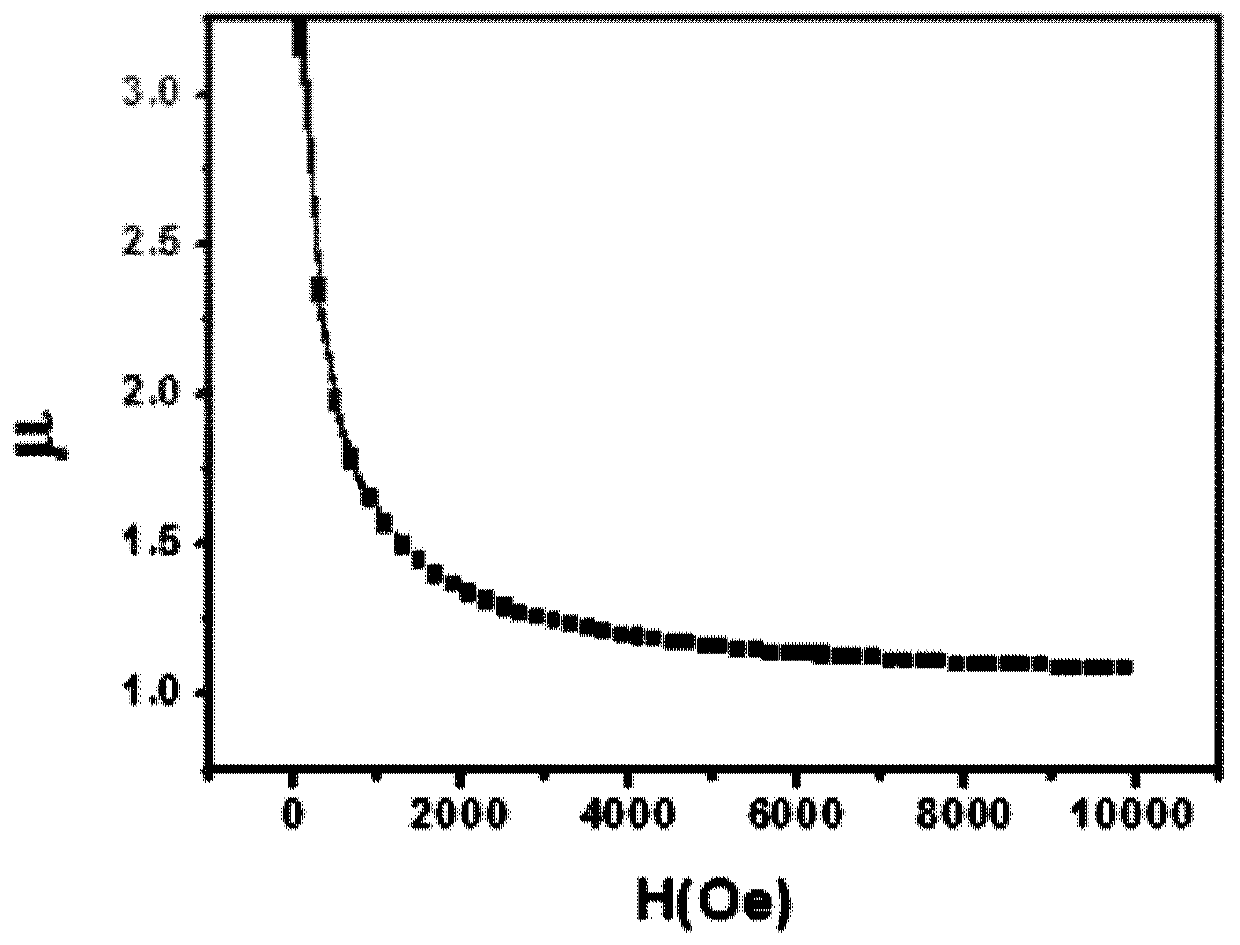

[0020] An embodiment of the present disclosure provides a spallation target material of tungsten alloy particles. The tungsten alloy adopts tungsten-nickel-iron alloy, and tungsten-nickel-iron alloy particles are used as the spallation target material. According to the requirements of the operating conditions of the ADS, pure tungsten metal is too brittle, so this embodiment adopts tungsten alloy to improve the toughness and anti-abrasion performance of the tungsten material. The tungsten content of the tungsten alloy particles is greater than 90% (mass ratio), and the rest is NiFe structure phase. The tungsten alloy of this embodiment has the best comprehensive performance as a spallation target material.

[0021] Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com