Combined extrusion coupling homogenization dehydration method

A combined, water-based technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of large loss of vitamin active ingredients, long drying cycle, difficult retention of color, aroma and taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Step 1: Grind 10g of corn, 5g of red beans, 5g of buckwheat, 10g of millet and 5g of oats, respectively pass through a 60-mesh sieve, then mix evenly, and dry at 50°C to obtain mixed powder;

[0067] Step 2: Perform twin-screw extrusion on the dried mixed powder, and cut it into granular materials by a cutting machine. The extrusion conditions are screw speed 150r / min, rod temperature 140°C, feeding speed 15kg / h, cutting machine speed 600r / min, the temperature of each zone in the extrusion condition is: temperature zone 1 is 60°C, temperature zone 2 is 120°C, temperature zone 3 is 140°C, temperature zone 4 is 120°C, temperature zone 5 is 110°C;

[0068] Step 3: Establish a dynamic model, the construction process is:

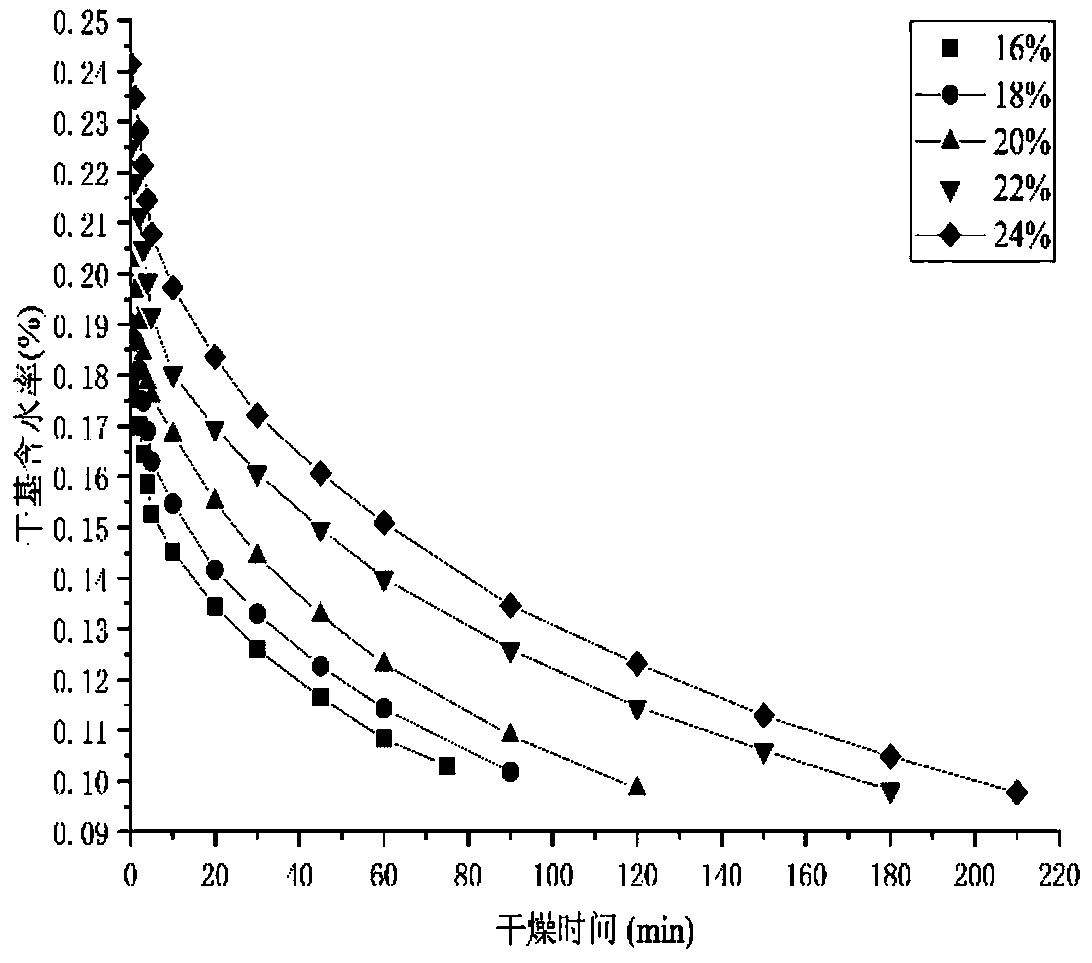

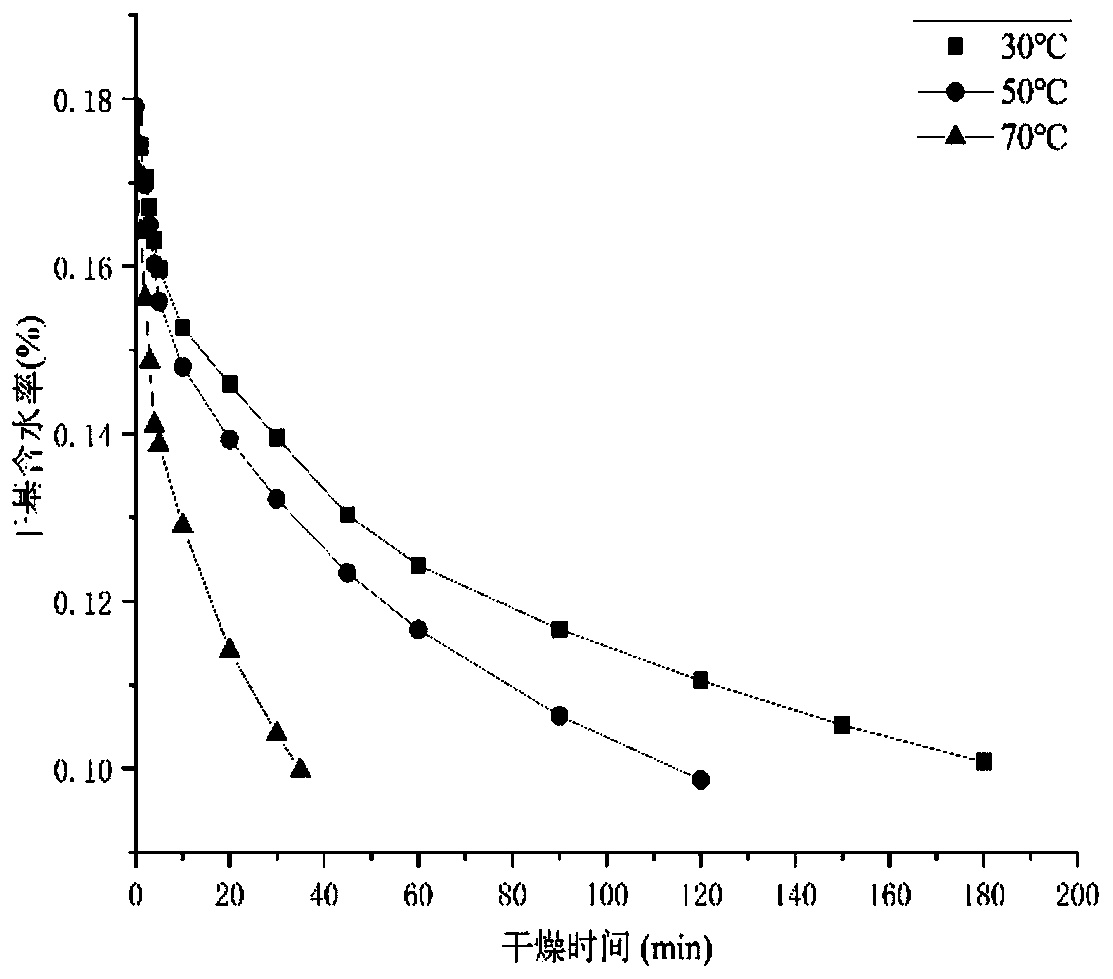

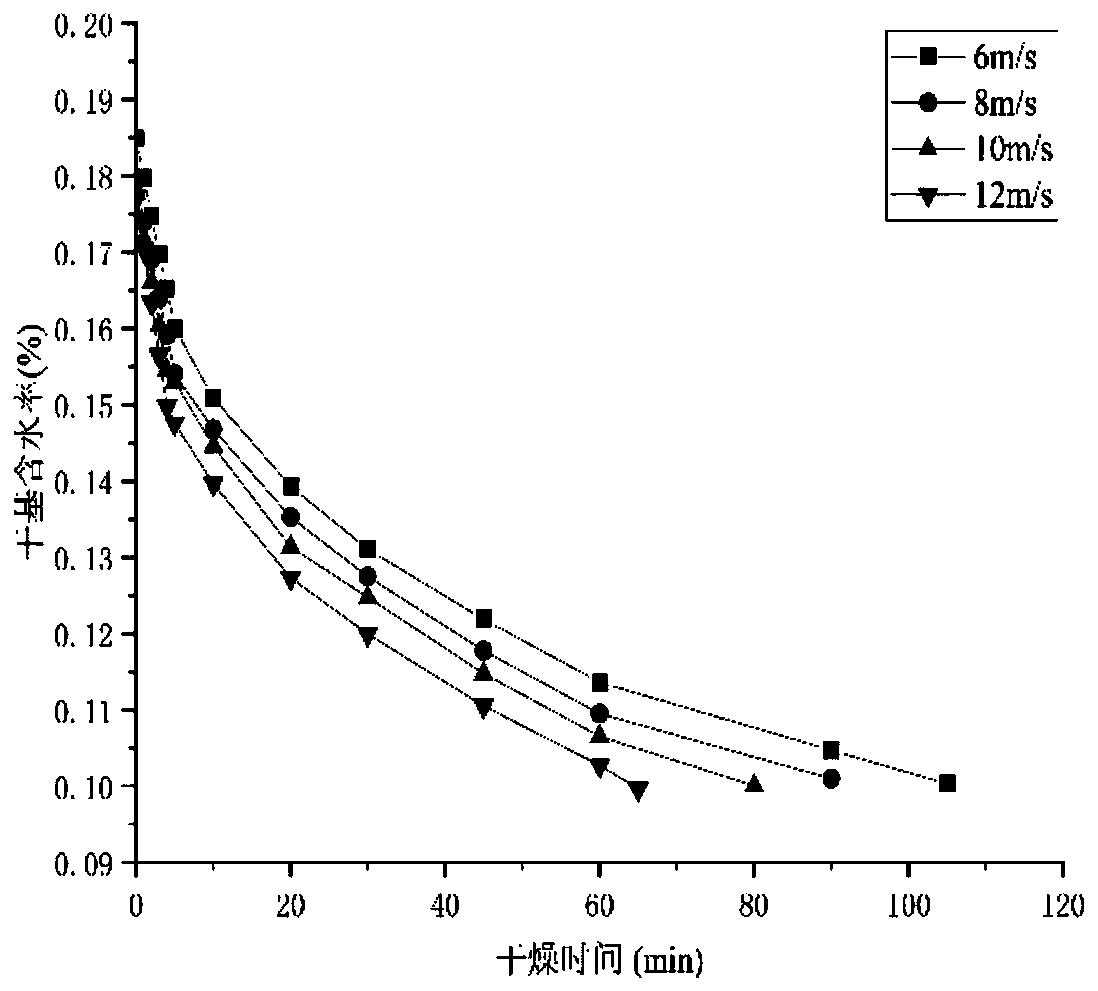

[0069] Under different drying schemes, the linear fitting equation of homogenized dehydration is given by Figure 1-3 It can be seen that the drying curve is linearly fitted, and the homogenization dehydration fitting equation under different drying condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com