Assembled handrail

An assembled and railing technology, which is applied to building structures, stepped structures, buildings, etc., can solve the problems of unsightly appearance, troublesome and time-consuming processing, and easy to be damaged, so as to achieve the effect of beautiful overall structure, beautiful structure and increased hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

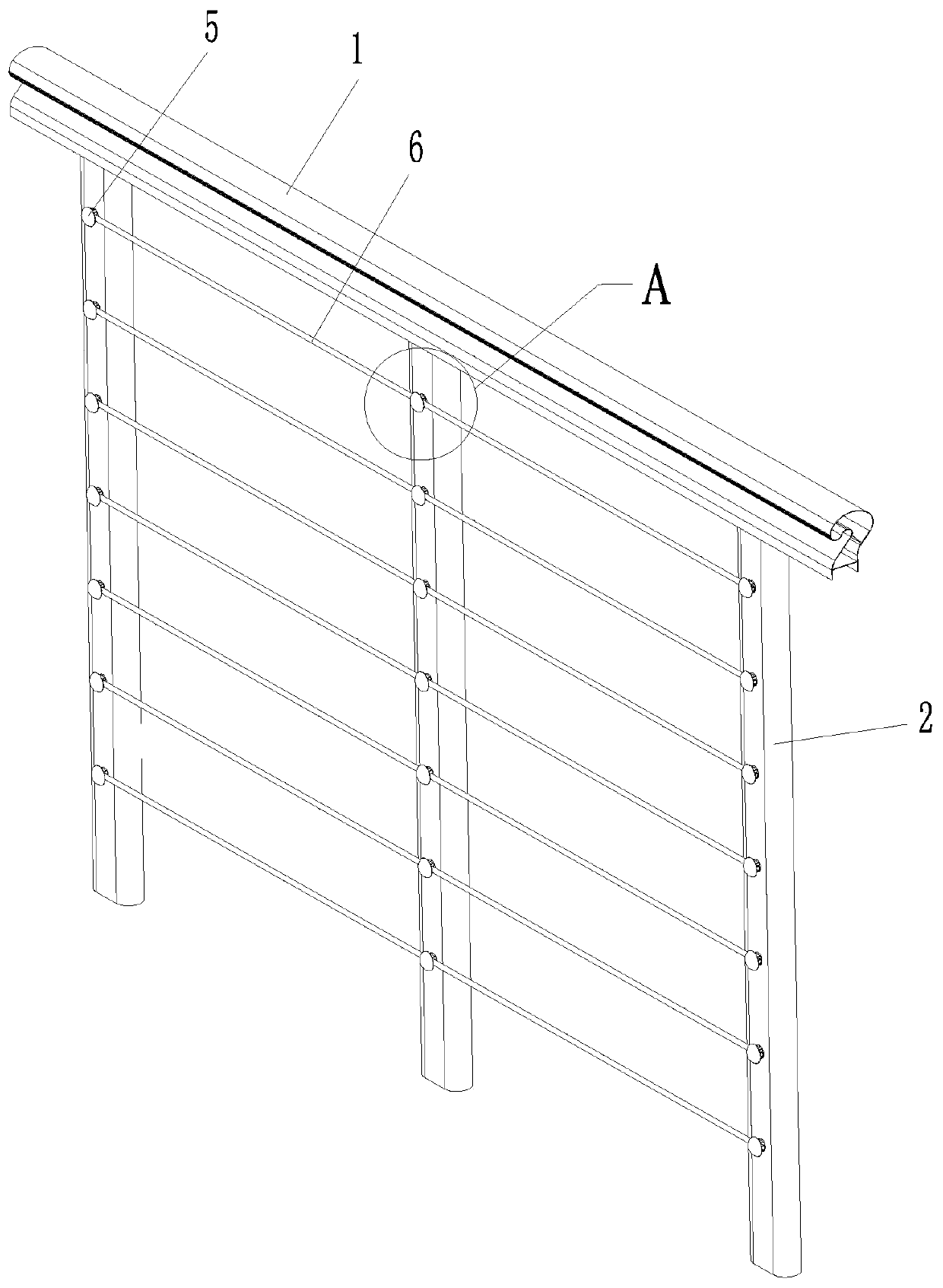

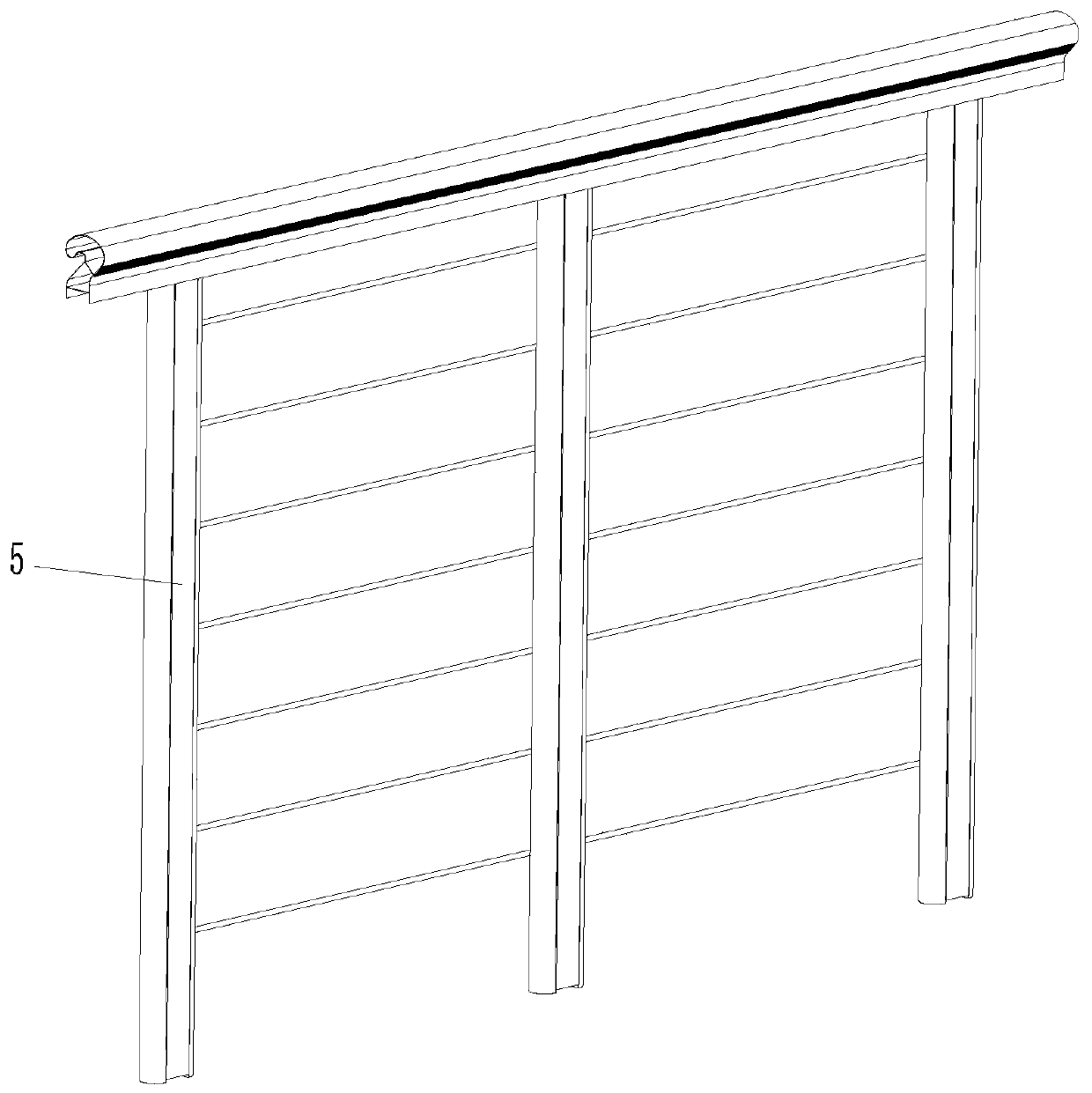

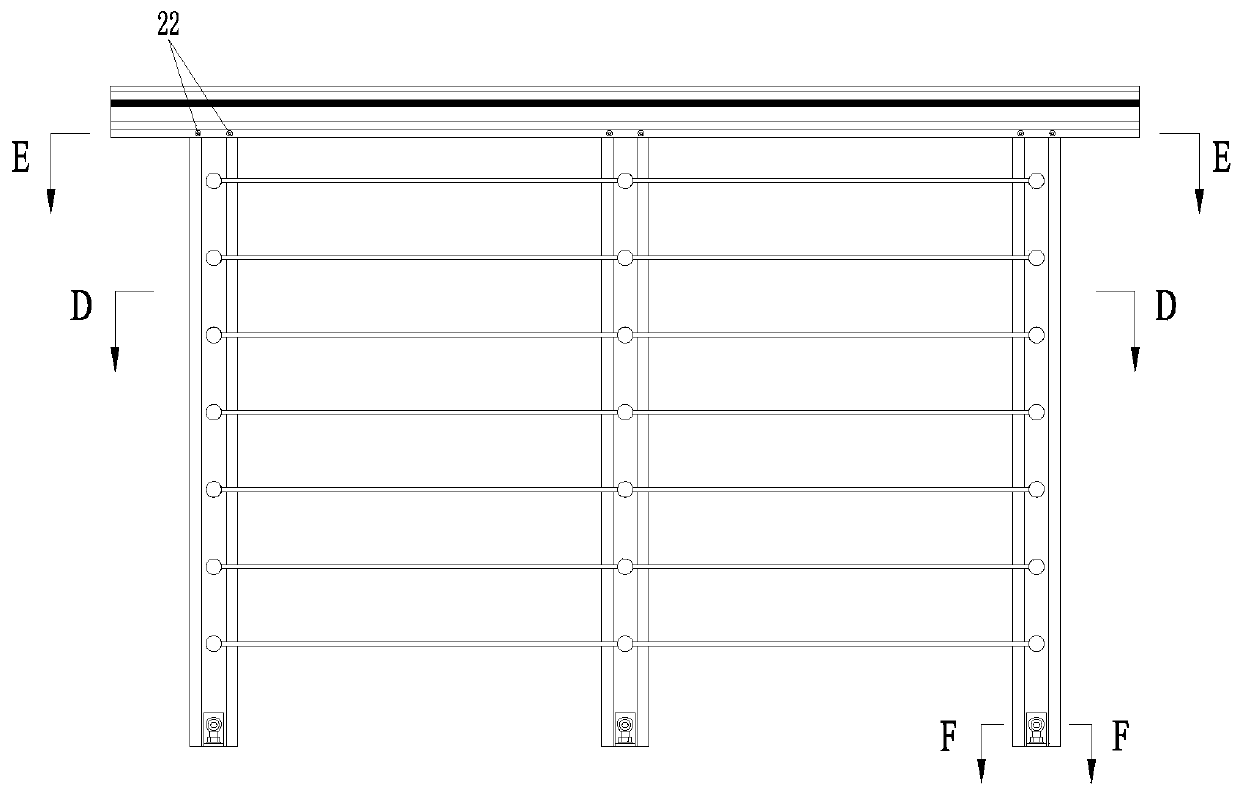

[0040] Such as image 3 As shown, in this embodiment, the front side of the column 2 is arranged with a plurality of through mounting holes along the vertical direction, the beam 6 is a round bar, and the through holes on the corresponding mounting bolts 5 are circles matching the cross-sectional size of the round bar. The holes, the columns 2 are lined up on the same vertical plane, the beams 6 pass through the through holes corresponding to the mounting bolts 5 on all the columns 2 on the same vertical plane, and the corresponding mounting bolts 5 can be at the same height, so that the beams 6 are horizontally arranged , can also be arranged according to a certain rule, so that the beam 6 is arranged obliquely. Simultaneously, at the outermost side of the same vertical plane, a second limiting plate can be set, and one end of the crossbeam 6 is against the limiting plate to ensure that the ends of the crossbeam 6 are arranged neatly, and the limiting plate can be located on ...

Embodiment 2

[0042] Such as Figure 11 As shown, the difference between the second embodiment and the first embodiment is that the crossbeam 6 does not pass through the through holes corresponding to the mounting bolts 5 on all the columns 2 on the same vertical plane, but only passes through some of the through holes, leaving appropriate vacancies To increase the aesthetic feeling, the inclination angles of the beams 6 on both sides can be inconsistent by adding vacancies. The so-called vacancies mean that there is no position for installing the beams 6, so the vacancies should not be too large, otherwise there will be safety hazards.

Embodiment 3

[0044] Such as Figure 12 As shown, the front side of the column 2 is arranged with a plurality of installation hole groups along the vertical direction. The installation hole group includes two installation holes. To form a railing unit, the mounting bolts 5 located on the two columns 2 of the same railing unit and close to the inside of the railing unit are the first mounting bolts 27, and the two ends of the beam 6 respectively pass through two corresponding first mounting bolts 27 located on both sides of the railing unit via holes on the

[0045] In this embodiment, one column 2 is equivalent to two sets of mounting bolts 5 arranged longitudinally, and the beam 6 only passes through the through holes on the mounting bolts 5 on the inner side of the two adjacent columns 2, so the beam 6 can be made More diverse overall effects, such as on the same vertical plane, the overall effect of the beam 6 is in the shape of a broken line.

[0046] Preferably, a first limiting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com