Multi-stage pore pipe weir shunting silting method

A technology of multi-level holes and hole tubes, applied in barrage/weirs, water conservancy projects, sea area projects, etc., can solve problems such as unfavorable embankment safety, embankment safety threats, flood floodplains, etc., and achieve high construction efficiency and stress-bearing conditions Good, wide range of sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

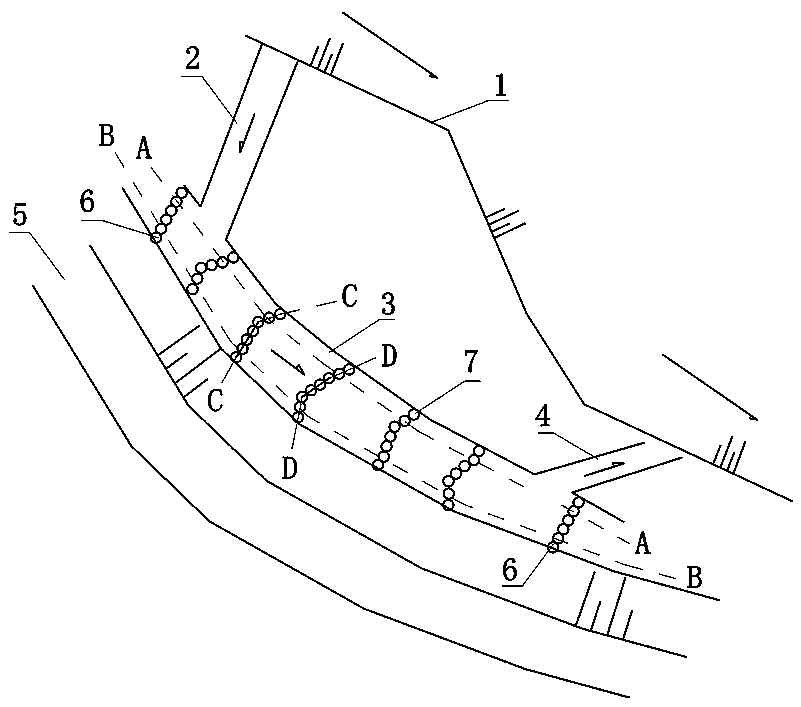

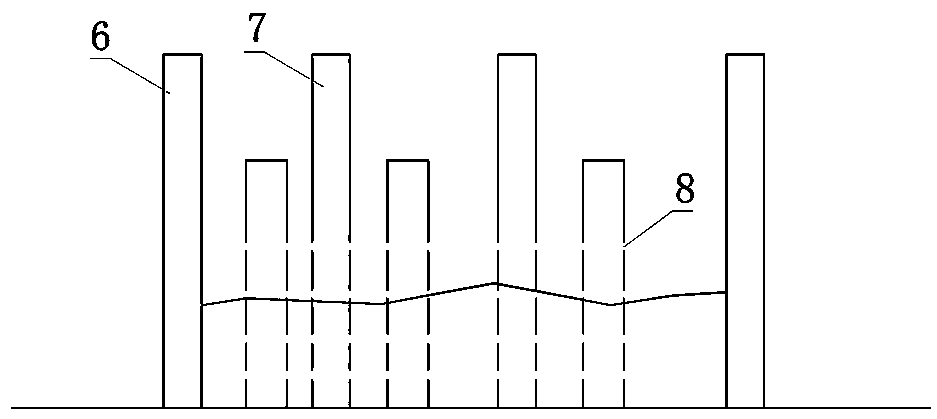

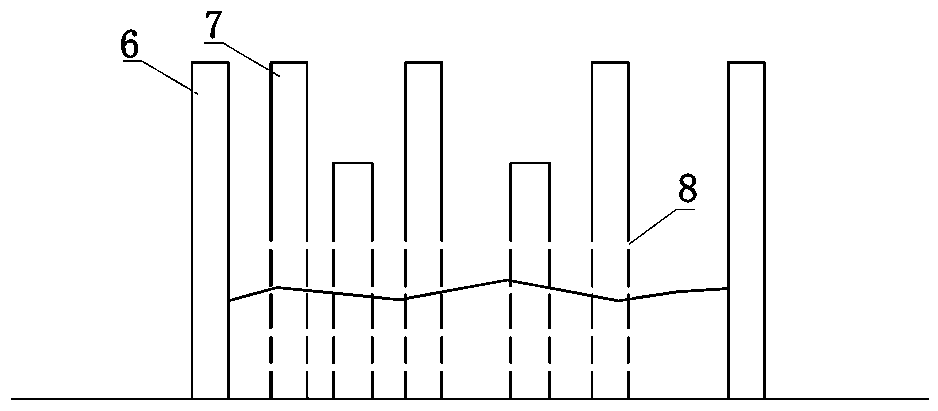

[0030] like Figure 1-6 Shown, the multi-stage hole tube weir diversion discharge method for silting of the present invention, comprises the following steps:

[0031] Step 1. Excavate the water diversion channel 2 upstream of the river main channel 1 where the silt should be released to the embankment root depression area 3. The angle between the axis of the water diversion channel 1 and the flow direction of the river main channel 1 is less than 45° and smoothly connected. The size of the excavation section is comprehensively determined by the determined water di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com