Preparation method of high-purity gold for electron industry

An electronic industry, pure gold technology, applied in the field of high-purity precious metal preparation, can solve the problems of carry-in, poor surface cleanliness, affecting chip performance, etc., and achieve the effect of good smelting cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

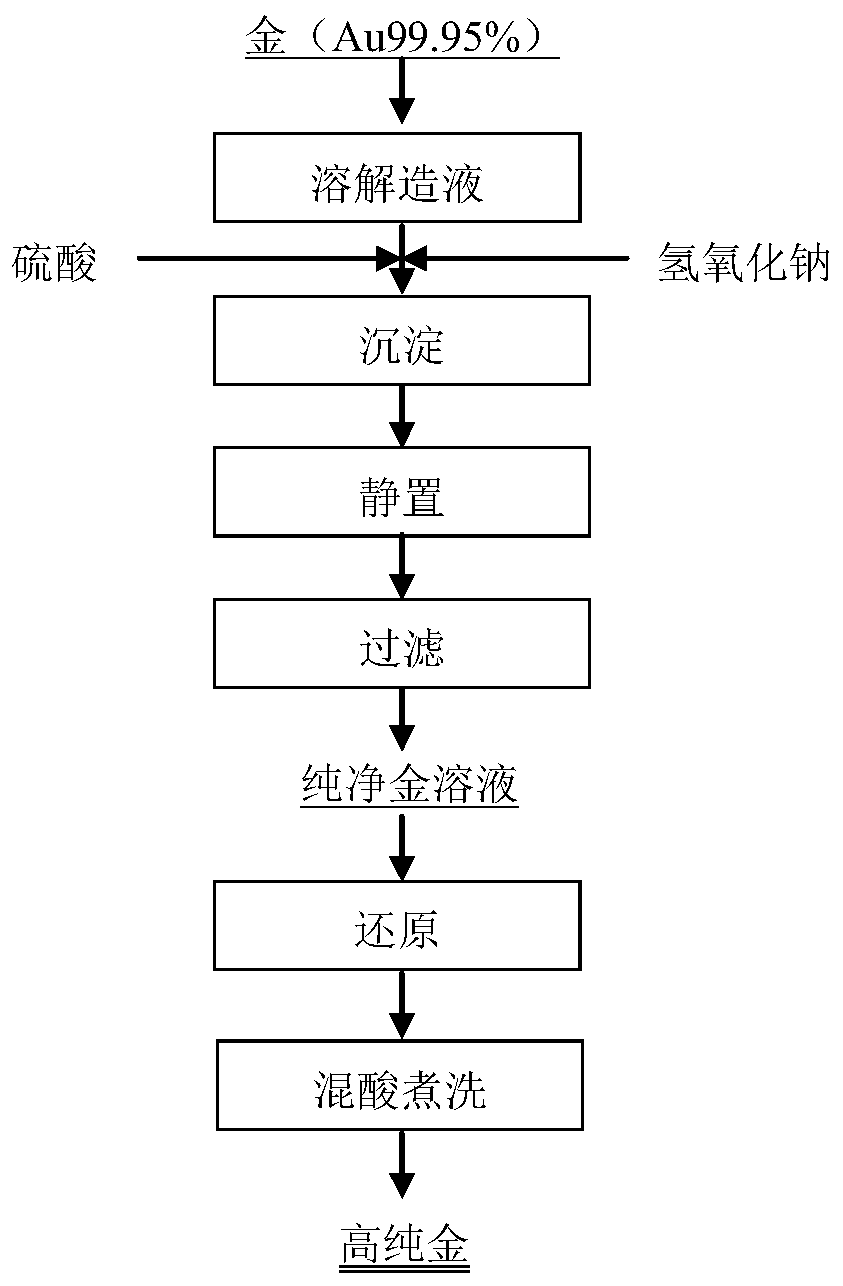

[0017] Embodiment 1, see attached figure 1 , after rolling gold ingots (Au 99.95%), using aqua regia to dissolve and nitrate to obtain a chloroauric acid solution; adding sulfuric acid to maintain a concentration of 0.001mol / L, then using sodium hydroxide to adjust the pH=1 of the solution, and standing After 24 hours, the solution was filtered under reduced pressure with a 0.1 μm filter membrane to obtain a pure gold solution; slowly add superior pure hydrazine hydrochloride to this solution, stir, and fully reduce until the solution is nearly colorless, filter, and fully wash with deionized water , to obtain gold powder; put the gold powder in a polytetrafluoroethylene container, use 30% nitric acid + 20% hydrofluoric acid mixed solution, stir and boil for 60 minutes, filter, fully wash with 80°C deionized water until neutral, and vacuum dry Finally, high-purity gold is obtained.

Embodiment 2

[0018] Embodiment 2, see attached figure 1 , after rolling gold ingots (Au 99.95%), using aqua regia to dissolve and nitrate to obtain a chloroauric acid solution; add sulfuric acid to maintain a concentration of 0.001mol / L, then use sodium hydroxide to adjust the pH of the solution to 3, and let it stand After 24 hours, the solution was filtered under reduced pressure using a 0.2 μm filter membrane to obtain a pure gold solution; slowly add superior pure hydrazine hydrochloride to this solution, stir, and fully reduce until the solution is nearly colorless, filter, and fully wash with deionized water , to obtain gold powder; put the gold powder in a polytetrafluoroethylene container, use 30% nitric acid + 20% hydrofluoric acid mixed solution, stir and boil for 60 minutes, filter, fully wash with 80°C deionized water until neutral, and vacuum dry Finally, high-purity gold is obtained.

Embodiment 3

[0019] Embodiment 3, see attached figure 1 , after gold ingot (Au 99.95%) is rolled into slices, use aqua regia to dissolve, catch up with nitrate, obtain chloroauric acid solution; add sulfuric acid to keep concentration 0.001mol / L, then adopt sodium hydroxide to adjust solution pH=2, leave standstill After 24 hours, the solution was filtered under reduced pressure using a 0.1 μm filter membrane to obtain a pure gold solution; slowly add superior pure hydrazine hydrochloride to this solution, stir, and fully reduce until the solution is nearly colorless, filter, and deionize with 80°C Fully wash with water to obtain gold powder; place the gold powder in a polytetrafluoroethylene container, use a mixed solution of 30% nitric acid + 20% hydrofluoric acid, stir and boil for 60 minutes, filter, and fully wash with 80°C deionized water until neutral , after vacuum drying, high-purity gold was obtained.

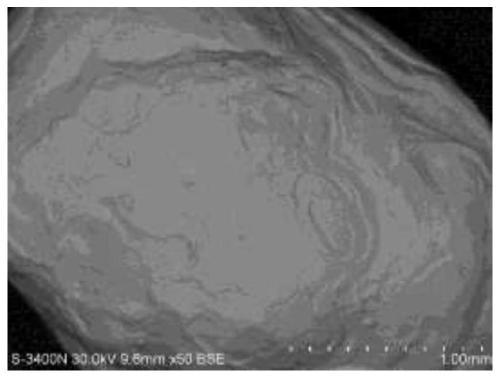

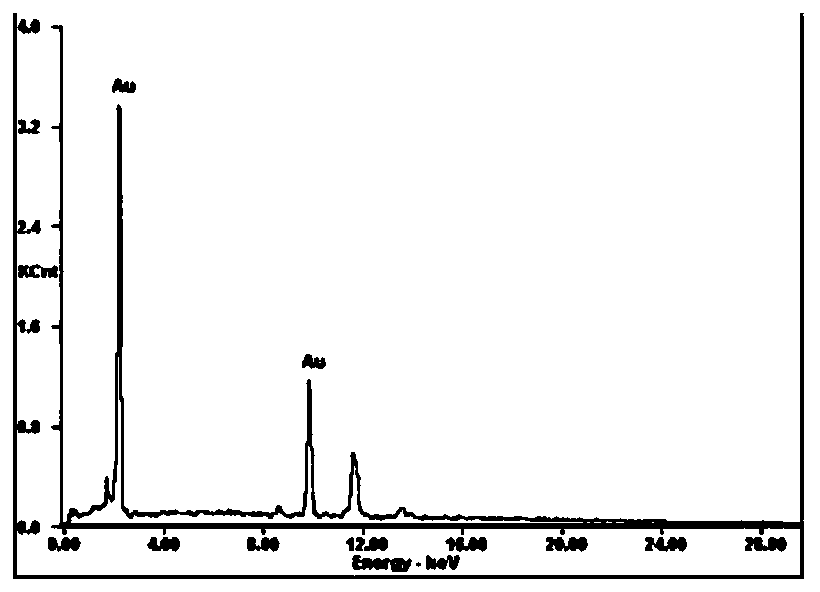

[0020] The typical high-purity gold prepared by the present invention adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com