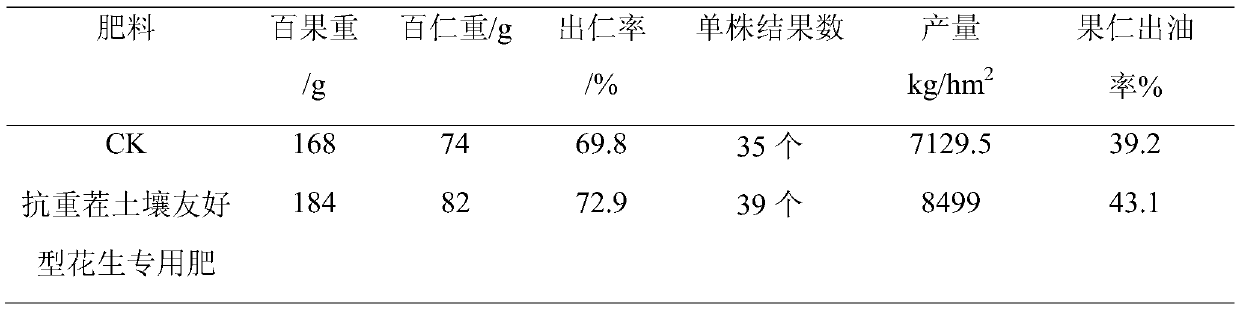

Continuous cropping-resistant and soil-friendly special fertilizer for peanuts

A special fertilizer for peanuts, friendly technology, applied in the direction of application, fertilization device, fertilizer mixture, etc., can solve the problem of secondary pollution, common chemical fertilizer price, expensive, etc., to achieve the effect of abundant raw materials, low cost, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: a kind of anti-repeatable soil-friendly special fertilizer for peanuts of the present invention is calculated by the following weight percentages: urea 7.5%, ammonium chloride 16.1%, monoammonium phosphate 22.7%, potassium chloride 16.6% and clay mineral particle control Release agent 37.1% made of: of which,

[0016] 1), mixing urea, ammonium chloride and clay mineral particle controlled release agent together to make initial material;

[0017] 2), mixing potassium chloride with the initial material to make a premix;

[0018] 3) Mix the monoammonium phosphate and the premix evenly to make granules;

[0019] 4) Dry and sieve the granules so that more than 90% of the granules with a particle size of 3.35-5.6mm are finished products;

[0020] The clay mineral particle controlled release agent is composed of agricultural sodium tetraborate and bauxite tailings slag with a weight ratio of 0.015:0.8;

[0021] The mass content of urea nitrogen is 46.4%, the m...

Embodiment 2

[0022] Embodiment 2: a kind of soil-friendly special fertilizer for anti-heavy cropping of the present invention is calculated by the following weight percentages: urea: 1%, ammonium chloride 23.5%, monoammonium phosphate 35.9%, potassium chloride 6.7% and clay mineral particles Controlled release agent 32.9%, the preparation method is the same as

[0023] Example 1.

Embodiment 3

[0024] Embodiment 3: a kind of anti-heavy cropping soil-friendly special fertilizer for peanuts of the present invention is calculated by the following weight percentages: urea: 15.2%, ammonium chloride 1.5%, monoammonium phosphate 20.7%, potassium chloride 18.6% and clay mineral particles Controlled release agent 44% is made, and preparation method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com