A metal-organic framework-based copper-silicon catalyst and its preparation and application

A technology of metal-organic frameworks and catalysts, applied in catalyst activation/preparation, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of copper agglomeration, poor thermal stability, easy sintering and decomposition, etc., and achieve small particle size and high stability Good, excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

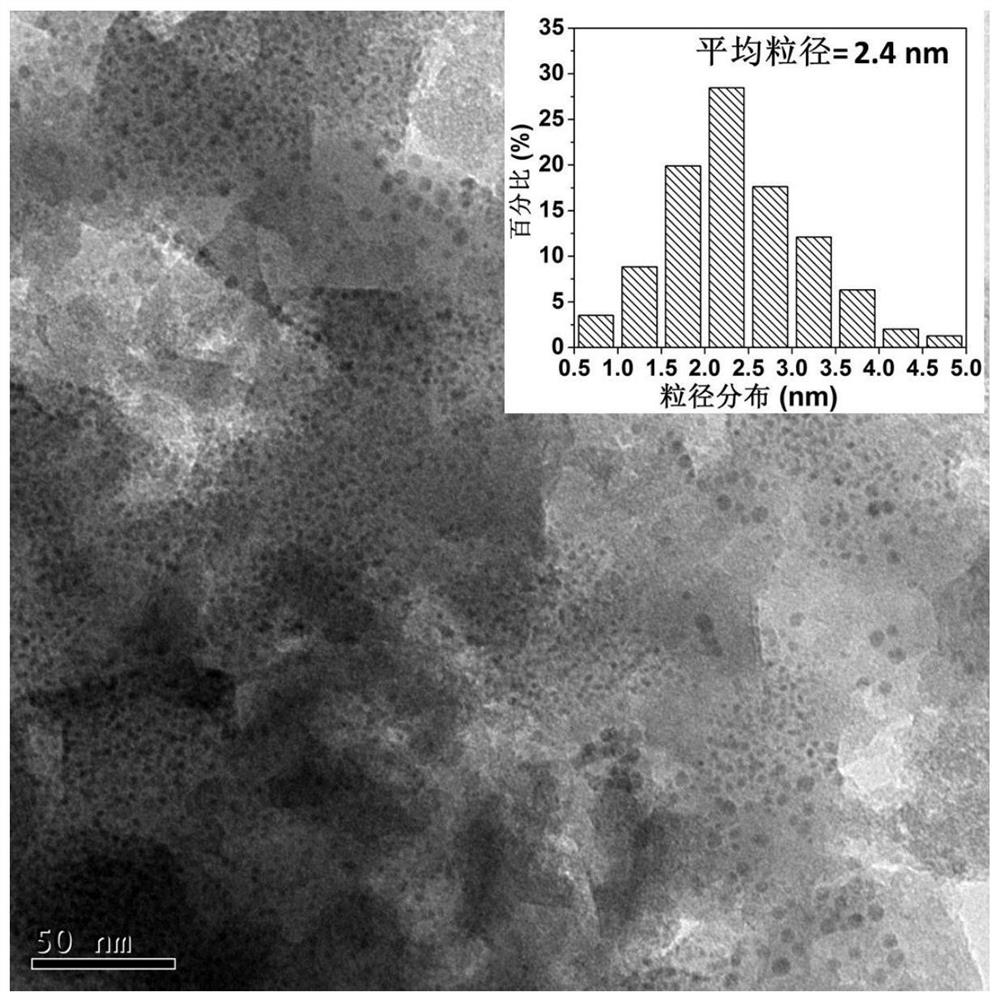

[0028] Embodiment 1: Prepare Cu / SiO with copper acetate as copper source 2 -1 catalyst

[0029] A. Dissolve 1.5g of copper acetate monohydrate and 1.05g of trimesic acid in 8mL of absolute ethanol, stir for 20min, then sonicate for 30min, then react at 65°C for 48h, cool and filter, and wash with absolute ethanol several times filter cake, place the filter cake in a 50°C oven and dry for 5 hours to obtain a metal-organic framework [Cu 3 (BTC) 2 ]. 5.0 g [Cu 3 (BTC) 2 ] was added to a mixed solution of 22.0g distilled water, 37.0g absolute ethanol and 28.5g tetraethyl orthosilicate, stirred at a constant temperature in a water bath at 65°C for 1 to 3 hours to form a sol-gel; aged at room temperature for 24 hours , and then carry out programmed temperature-controlled drying in an oven. The drying program is to dry at 65°C for 7h, at 70°C for 7h, at 100°C for 40h, and then at 120°C for 4h to obtain the dried [Cu 3 (BTC) 2 ] / SiO 2 -1 sample.

[0030] B. Combine the above ...

Embodiment 2

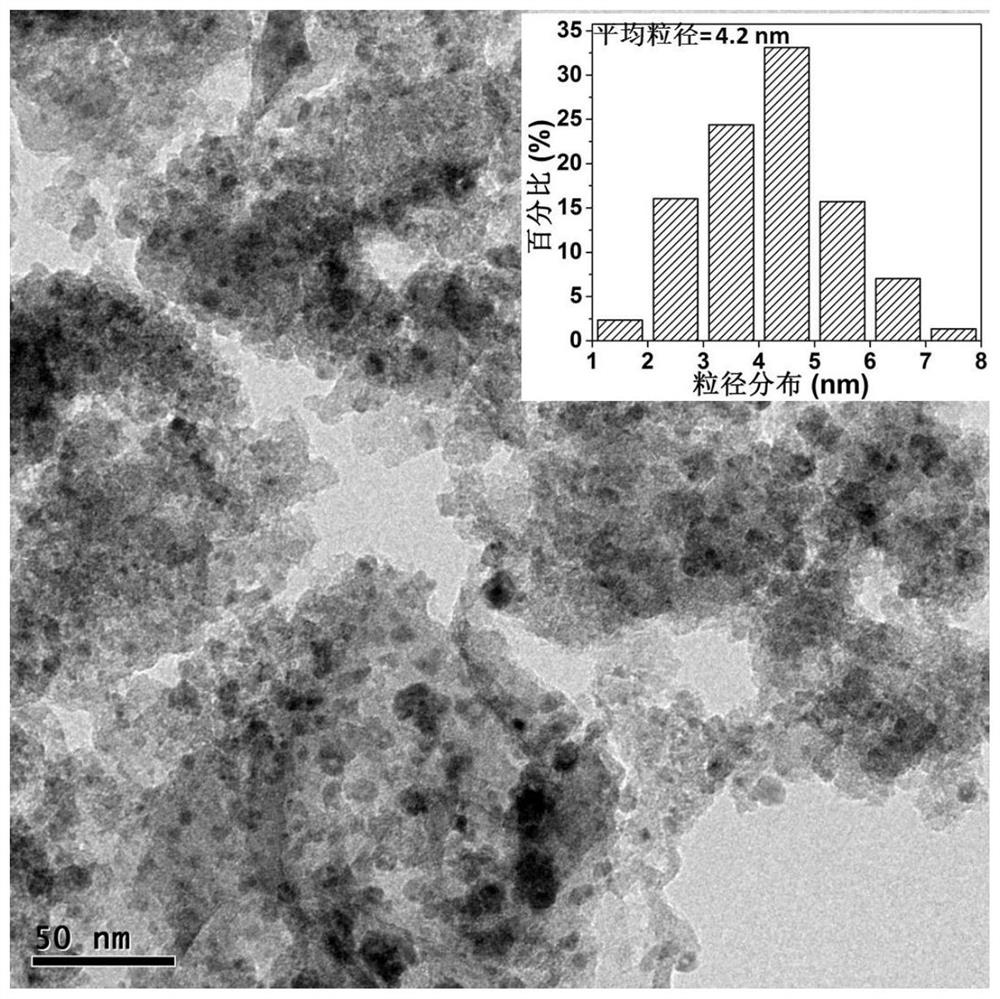

[0039] Embodiment 2: Prepare Cu / SiO with copper nitrate as copper source 2 -2 Catalyst

[0040] Cu / SiO 2 -2 The preparation steps of the catalyst are as follows: Dissolve 2.34g of copper nitrate trihydrate in 50mL of absolute ethanol at 60°C, then add 50mL of N,N-dimethylformamide containing 1.35g of trimesic acid solution, and continuously After stirring for 20 minutes, put it in an ultrasonic instrument for 60 minutes of ultrasonic oscillation, then transfer it to a reaction kettle at 85 ° C for 12 hours and then filter it. The cake was dried in an oven at 60°C for 6 hours to obtain a metal-organic framework [Cu 3 (BTC) 2 ]. 4.0g [Cu 3 (BTC) 2 ] was added to a mixed solution of 17.6g of distilled water, 29.6g of absolute ethanol and 22.8g of tetraethyl orthosilicate, stirred at a constant temperature in a water bath at 70°C for 1 to 3 hours to form a sol-gel; it was aged at room temperature for 24 hours , and then carry out programmed temperature-controlled drying in ...

Embodiment 3

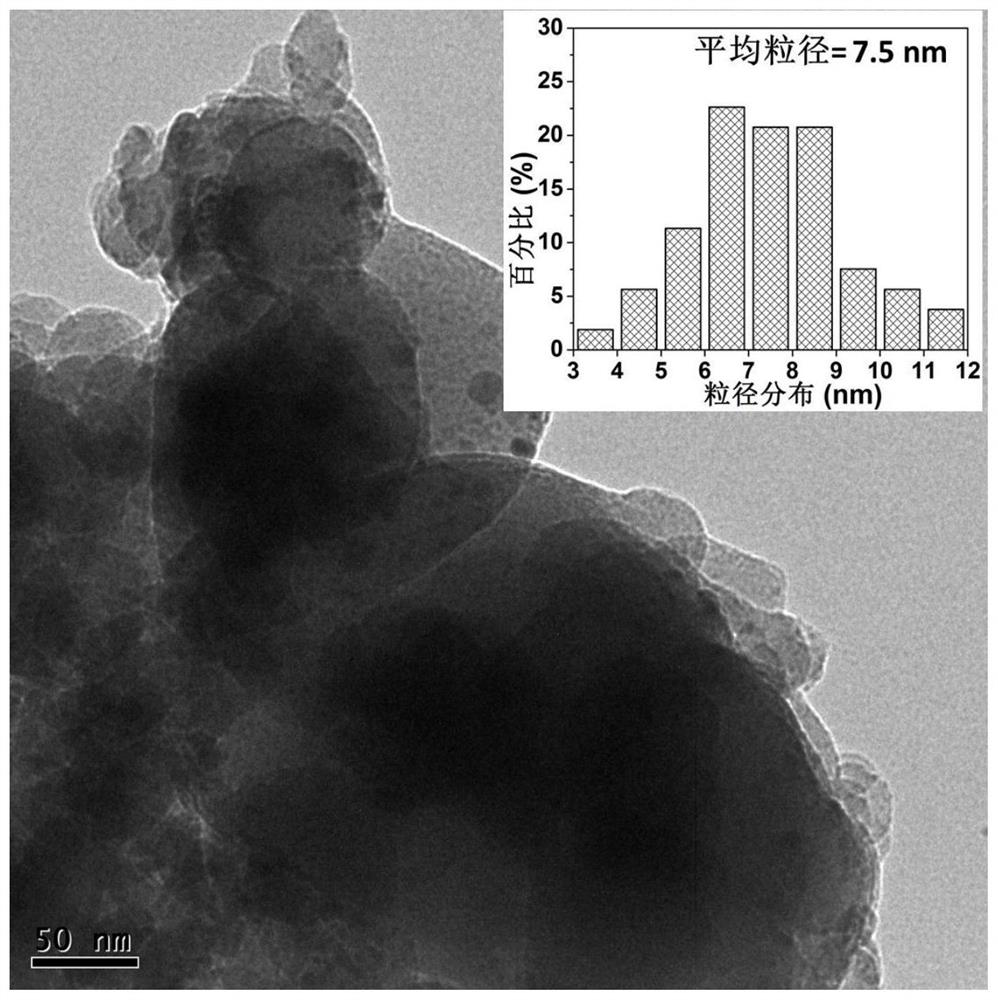

[0042] Embodiment 3: increase calcination temperature and time to prepare Cu / SiO 2 -3 Catalyst

[0043] Cu / SiO 2 The preparation steps of -3 catalyst are as follows: prepare [Cu by embodiment 1 step A 3 (BTC) 2 ] / SiO 2 -3 samples, and then placed in a muffle furnace at 500 ° C for 8 h, and then in a pure hydrogen atmosphere of 200 mL / min, the temperature was raised to 300 ° C for 4 h reduction, and the prepared catalyst was expressed as Cu / SiO 2 -3. Among them, the Cu loading is 8.27%; the specific surface area of the catalyst is 406.8m 2 g -1 .

[0044] According to the evaluation conditions of Example 1, the hydrogenation reaction activity of dimethyl oxalate was evaluated, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com