Air purification material and its preparation method and application

An air purification material, tourmaline powder technology, applied in chemical instruments and methods, separation methods, disinfection and other directions, can solve the problems of limited adsorption capacity, unsatisfactory effect, high price, and achieve the effect of improving the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] According to one aspect of the present invention, a kind of preparation method of above-mentioned air purification material, described preparation method comprises the following steps:

[0043] Firstly, the purification molecules are fully dissolved in water to obtain a purification molecule solvent, then the microporous ceramic particles are immersed in the solvent to fully absorb the purification molecules, and then the microporous ceramic particles adsorbed with the purification molecules are dried to obtain the air purification material.

[0044] Preferably, the water is deionized water.

[0045] The preparation method of the air purification material provided by the present invention, the method first fully dissolves the purification molecules in water to obtain a purification molecule solvent, then immerses the microporous ceramic particles in the solvent to fully absorb the purification molecules, and then the micropores adsorbed with the purification molecules T...

Embodiment 1

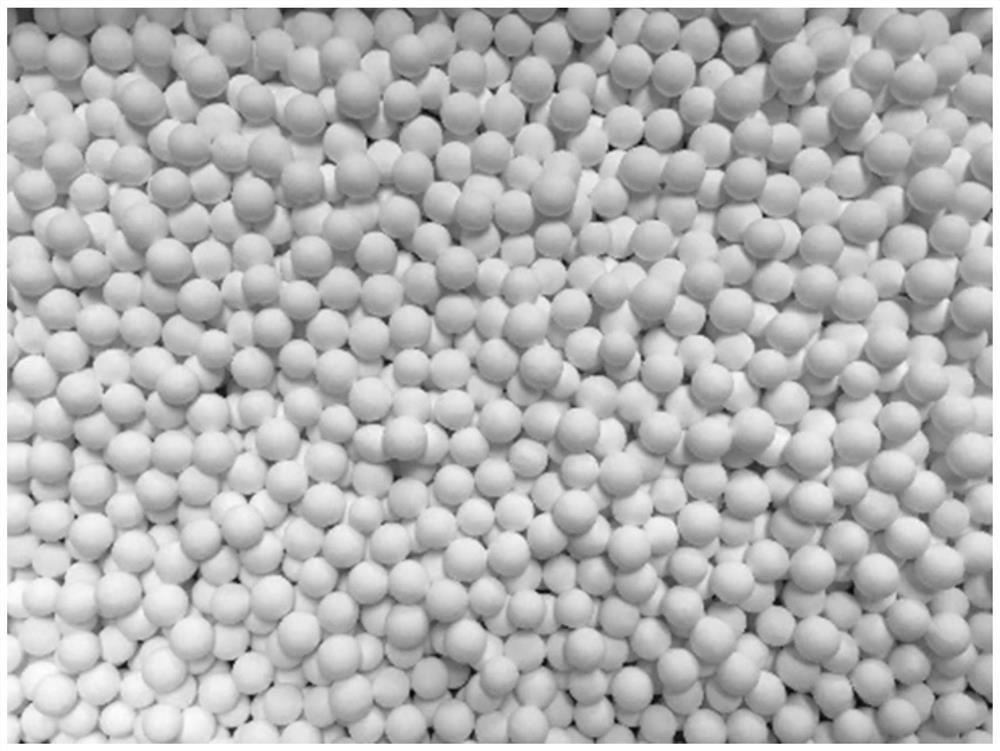

[0057] Such as figure 1 As shown, an air purification material, the air purification material is microporous ceramic particles with purification molecules attached in the pores;

[0058] The purification molecule is mainly composed of the following raw materials in terms of weight percentage: 70 wt% of titanium dioxide phosphate, 20 wt% of tourmaline powder and 10 wt% of Ag nano particles.

[0059] The particle size of the titanium dioxide phosphate is 2 nm, the particle size of the tourmaline powder is 5 nm, and the particle size of the Ag nanoparticles is 10 nm.

[0060] The preparation method of above-mentioned air purification material, comprises the following steps:

[0061] First, fully dissolve the purification molecules in deionized water to obtain a purification molecular solvent with a solid content of 8%, then immerse microporous ceramic particles with a particle size of 5 μm in the above solvent to fully absorb the purification molecules, and then the micropores a...

Embodiment 2

[0063] An air purification material, the air purification material is microporous ceramic particles with purification molecules attached in the pores;

[0064] The purification molecule is mainly composed of the following raw materials in terms of weight percentage: 85 wt% of titanium dioxide phosphate, 10 wt% of tourmaline powder and 5 wt% of Ag nano particles.

[0065] The particle size of the titanium dioxide phosphate is 50 nm, the particle size of the tourmaline powder is 10 nm, and the particle size of the Ag nanoparticles is 5 nm.

[0066] The preparation method of above-mentioned air purification material, comprises the following steps:

[0067] First, fully dissolve the purification molecules in deionized water to obtain a purification molecular solvent with a solid content of 10%, then immerse microporous ceramic particles with a particle size of 100 μm in the above solvent to fully absorb the purification molecules, and then the micropores adsorbed with the purifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com