All-vanadium redox flow battery bipolar plate and preparation process thereof

A technology for all-vanadium redox flow battery and preparation process, which is applied in the field of bipolar plate for all-vanadium redox flow battery and its preparation technology, and can solve the problems of affecting battery efficiency and service life, poor corrosion resistance of electrolyte, and conductivity of pure graphite plate Advanced problems, to achieve the effect of uniform and controllable performance, good corrosion resistance and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] (1) The preparation of silane coupling agent and the treatment steps of grid carbon cloth are as follows:

[0043] Prepare a 0.5-1wt% silane coupling agent solution with ethanol and water as a solvent, soak the grid carbon cloth in it for 10-30 minutes, or spray the grid carbon cloth by spraying method, and let it stand until it is dry on the surface.

[0044] Grid carbon cloth: mesh size 1*1mm-10*10mm, thickness 0.2-1mm.

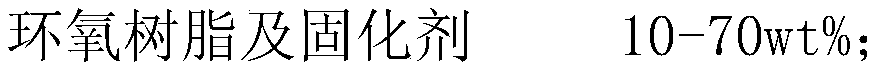

[0045] (2) The preparation steps of graphite-filled conductive adhesive are as follows:

[0046] A preparation process for a bipolar plate of an all-vanadium redox flow battery. The production process adopts an internal mixer and a flat vulcanizer, and the epoxy resin, graphite powder, conductive additive, curing agent, diluent and coupling The agent is divided into three groups, the epoxy resin and half of the graphite powder are the first group, the other half of the graphite powder and the conductive additive are the second group, the curing agen...

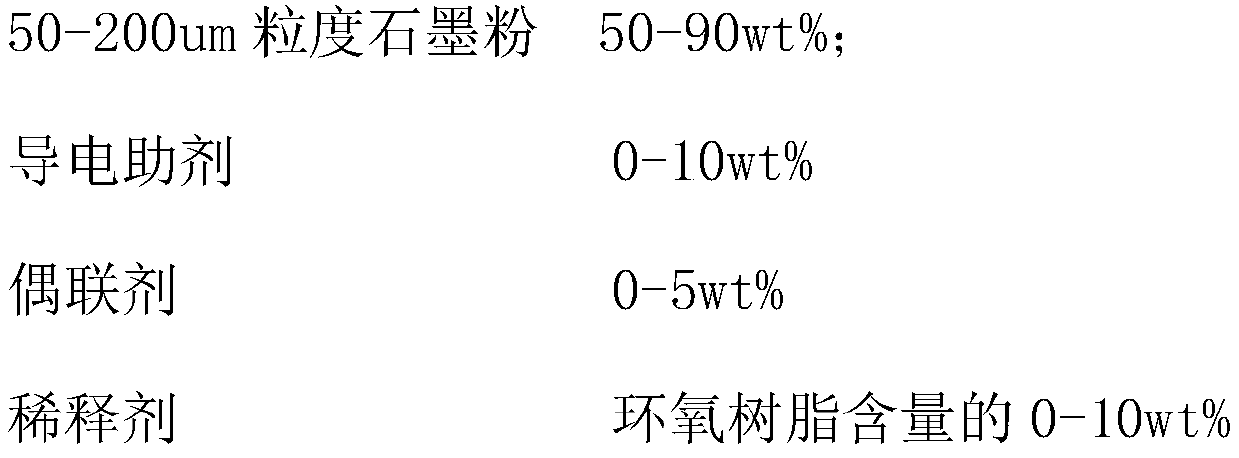

Embodiment 1

[0060] (1) Prepare a KH550 solution with a concentration of 0.5wt%, soak the grid carbon cloth in it for 30 minutes, take it out and dry it for later use.

[0061] (2) 20g epoxy resin E-44, 4g curing agent T31, 24g graphite powder, 0g carbon fiber, 0g carbon black, 0g diluent, 0.5g coupling agent, are placed in the internal mixer, rotating speed 20r / min, Knead to prepare graphite conductive adhesive premix.

[0062] (3) Take out the premix and place it in the mill, the speed of the mill is 10r / min, adjust the distance between the rollers to 0.5mm, remove the sheet after the milling is completed, and cut it for later use.

[0063] (4) Take a flexible graphite plate with a thickness of 1.6mm, treat the surface of one side of the flexible graphite plate with KH550 solution, and stack it in sequence according to the order of graphite plate, conductive adhesive sheet, grid carbon cloth, conductive adhesive sheet, and graphite plate, wherein KH550 Place the solution-treated surface...

Embodiment 2

[0065] (1) Prepare a KH550 solution with a concentration of 0.5wt%, soak the grid carbon cloth in it for 30 minutes, take it out and dry it for later use.

[0066] (2) 19g epoxy resin E-44, 4g curing agent T31, 22g graphite powder, 2g carbon fiber, 0g carbon black, 1g diluent, 0.5g coupling agent are placed in the internal mixer, the internal mixer speed 20r / min, kneading to prepare graphite conductive adhesive premix.

[0067] (3) Take out the premix and place it in the mill, the speed of the mill is 10r / min, adjust the distance between the rollers to 0.5mm, remove the sheet after the milling is completed, and cut it for later use.

[0068] (4) Take a flexible graphite plate with a thickness of 1.6mm, treat the surface of one side of the flexible graphite plate with KH550 solution, and stack it in sequence according to the order of graphite plate, conductive adhesive sheet, grid carbon cloth, conductive adhesive sheet, and graphite plate, wherein KH550 Place the solution-tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com