Tubular TiO2/carbon lithium ion battery negative electrode material and preparation method and application thereof

A lithium-ion battery, titanium dioxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cumbersome and complicated preparation process and high raw material cost, achieve simple operation process, improved electrical conductivity and lithium ion conductivity, large The effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

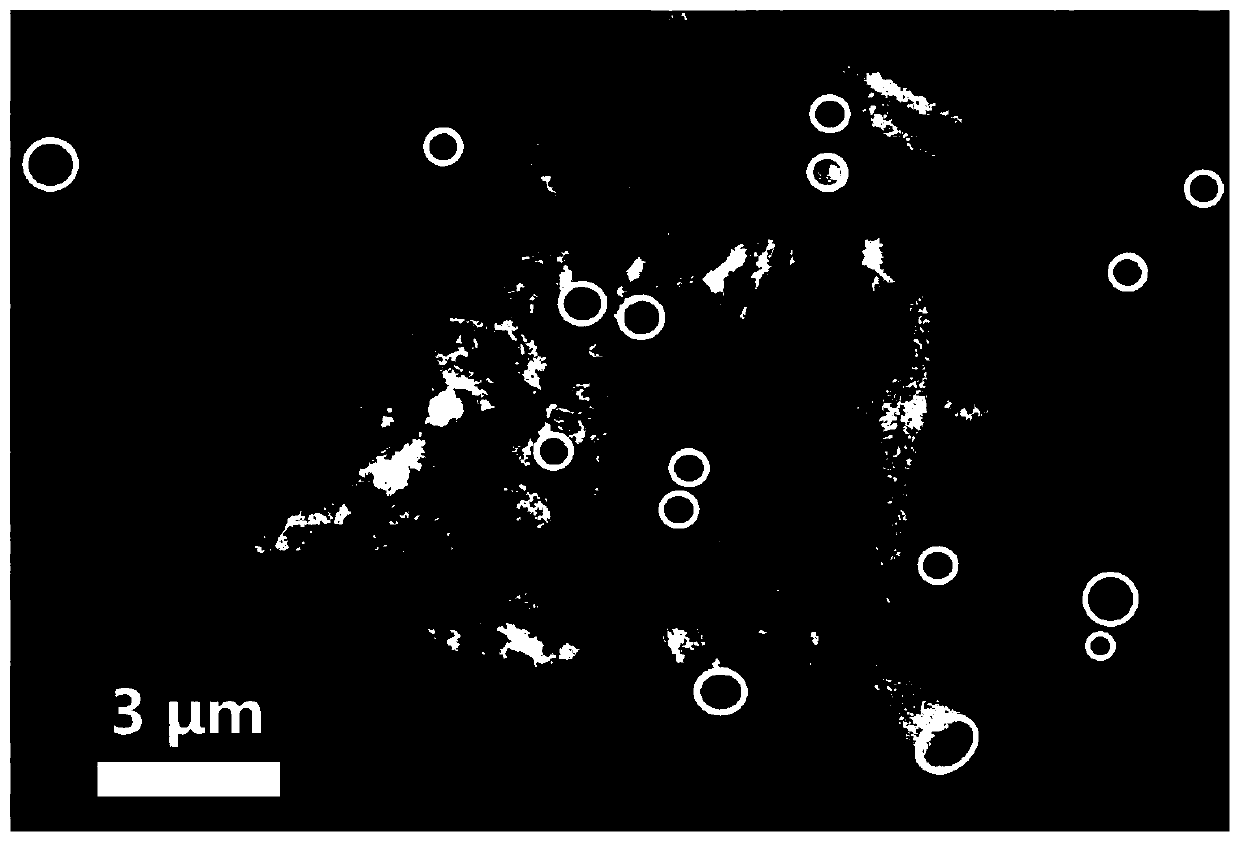

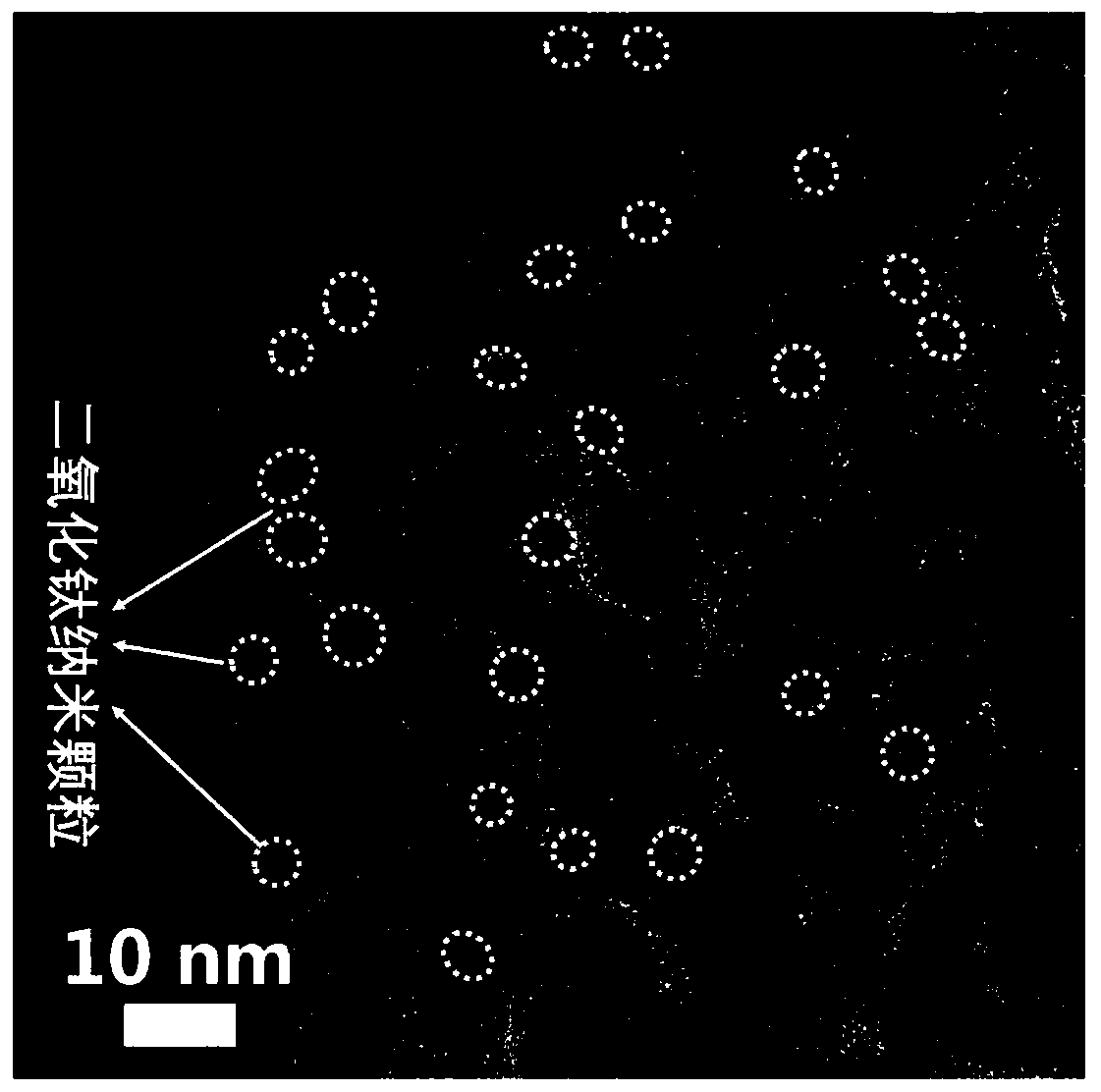

[0030] The preparation of tubular titanium dioxide / carbon lithium ion battery negative electrode material specifically comprises the following steps:

[0031] (1) Preparation of precursor solution: Weigh 0.0013 mol of titanyl sulfate, 0.13 mol of glycerol, 0.35 mol of ethanol and 0.09 mol of ether and mix well to obtain molecular sieve precursor solution;

[0032] (2) Preparation of organotitanium precursor: transfer the well-mixed precursor solution to a 50 mL polytetrafluoroethylene-lined reactor, continue to react at 110 °C for 2 days, and cool naturally to room temperature to obtain The final precipitated product was washed with an aqueous solution of ethanol at a volume ratio of 1:1, washed by centrifugation for 3 times, and dried at 100°C for 12 hours to obtain an organotitanium precursor;

[0033] (3) Sintering stage: The obtained organotitanium precursor was sintered at 600°C for 3 hours in an argon atmosphere, and cooled naturally to room temperature to obtain a finis...

Embodiment 2

[0039] The preparation of tubular titanium dioxide / carbon lithium ion battery negative electrode material specifically comprises the following steps:

[0040](1) Preparation of precursor solution: Weigh 0.001 mol of titanium tetrachloride, 0.1 mol of ethylene glycol, 0.3 mol of methanol and 0.05 mol of ether and mix well to obtain a molecular sieve precursor solution;

[0041] (2) Preparation of organotitanium precursor: Transfer the well-mixed precursor solution to a 50 mL polytetrafluoroethylene-lined reactor, continue to react at 100 °C for 3 days, and cool naturally to room temperature to obtain The final precipitated product is an aqueous solution of ethanol, wherein the volume ratio of ethanol to water is 1:0.5, centrifuged and washed 3 times, and dried at 60°C for 36 hours to obtain an organotitanium precursor;

[0042] (3) Sintering stage: The obtained organic titanium precursor was sintered at 450° C. for 10 hours in an argon atmosphere, and cooled naturally to room t...

Embodiment 3

[0046] The preparation of tubular titanium dioxide / carbon lithium ion battery negative electrode material specifically comprises the following steps:

[0047] (1) Preparation of precursor solution: Weigh 0.002 mol of titanyl sulfate, 0.2 mol of glycerol, 0.4 mol of ethanol and 0.15 mol of ether and mix well to obtain molecular sieve precursor solution;

[0048] (2) Preparation of organotitanium precursor: transfer the well-mixed precursor solution to a 100 mL polytetrafluoroethylene-lined reactor, continue the reaction at 200 °C for 1 day, and cool naturally to room temperature to obtain The final precipitated product is an aqueous solution of ethanol, wherein the volume ratio of ethanol to water is 2:0.5, centrifuged and washed 6 times, and dried at 100°C for 12 hours to obtain an organotitanium precursor;

[0049] (3) Sintering stage: The obtained organic titanium precursor was sintered at 700° C. for 2 hours in an argon atmosphere, and cooled naturally to room temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com