LDH-based supercapacitor composite electrode material and preparation method and application thereof

A technology of supercapacitors and composite electrodes, which is applied in the field of preparation of MnCo-LDH/C/NiMn-LDH composite electrode materials, can solve the problems of limiting the practical application of energy storage devices, too fast capacitance decay, etc., and achieves the promotion of electron and ion transport. , the effect of increasing the specific surface area and enhancing the transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

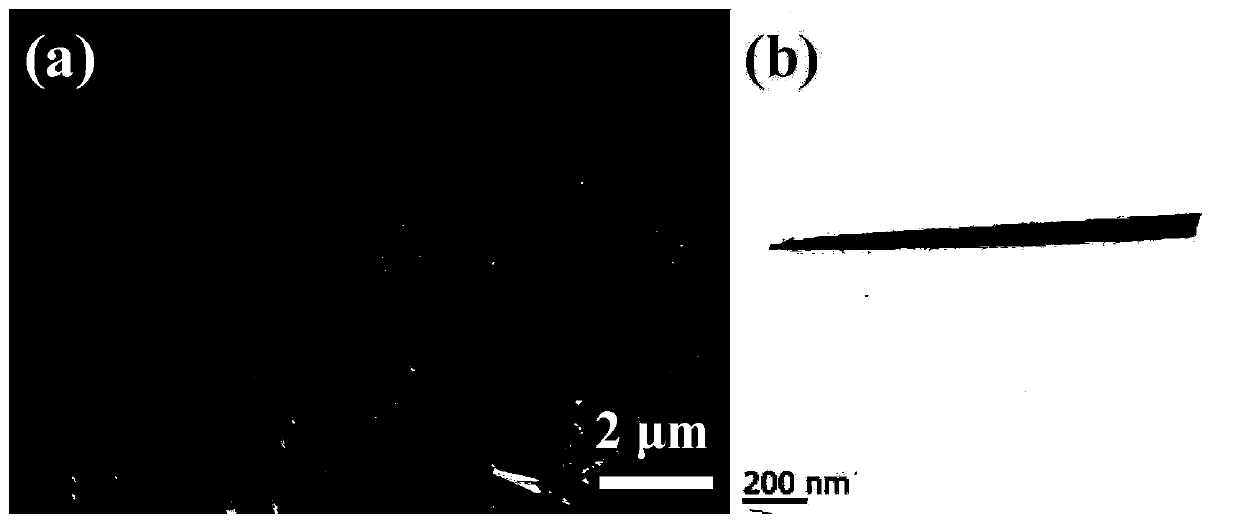

[0030] A kind of preparation and performance research of MnCo-LDH / C / NiMn-LDH composite electrode material based on nickel foam, comprising the following steps:

[0031] (1) Uniformly dissolve manganese nitrate tetrahydrate, cobalt nitrate hexahydrate, urea, and ammonium fluoride in 80 mL of deionized water to obtain dispersion 1. The amount of manganese nitrate tetrahydrate substance in the solution is 2mmol, the amount of cobalt nitrate hexahydrate substance is 4mmol, the amount of urea substance is 12mmol, and the amount of ammonium fluoride substance is 10mmol;

[0032] (2) Transfer the dispersion liquid 1 prepared in step (1) to a reaction kettle, put nickel foam (2cm×4cm), and conduct a hydrothermal reaction at 120° C. for 12 hours. The obtained MnCo-LDH based on nickel foam was rinsed three times with deionized water and ethanol respectively, and dried at 60°C for 8h;

[0033] (3) Soak the MnCo-LDH based on nickel foam obtained in step (2) in glucose solution for 24 h, ...

Embodiment 2

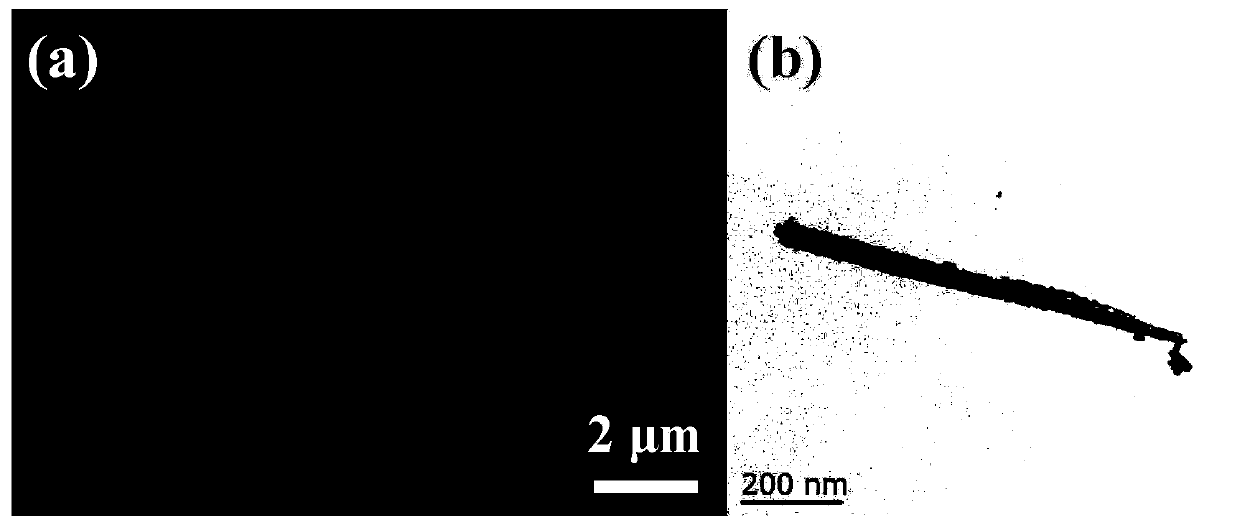

[0038] A kind of preparation and performance research of MnCo-LDH / C / NiMn-LDH composite electrode material based on nickel foam, comprising the following steps:

[0039] (1) Uniformly dissolve manganese nitrate tetrahydrate, cobalt nitrate hexahydrate, urea, and ammonium fluoride in 60 mL of deionized water to obtain dispersion 1. The amount of manganese nitrate tetrahydrate substance in the solution is 1mmol, the amount of cobalt nitrate hexahydrate substance is 3mmol, the amount of urea substance is 8mmol, and the amount of ammonium fluoride substance is 8mmol;

[0040] (2) Transfer the dispersion liquid 1 prepared in step (1) to a reaction kettle, put nickel foam (2cm×4cm), and conduct a hydrothermal reaction at 150°C for 10h. The obtained MnCo-LDH based on nickel foam was rinsed three times with deionized water and ethanol respectively, and dried at 60°C for 8h;

[0041] (3) Soak the MnCo-LDH based on foamed nickel obtained in step (2) in glucose solution for 24 h, and the...

Embodiment 3

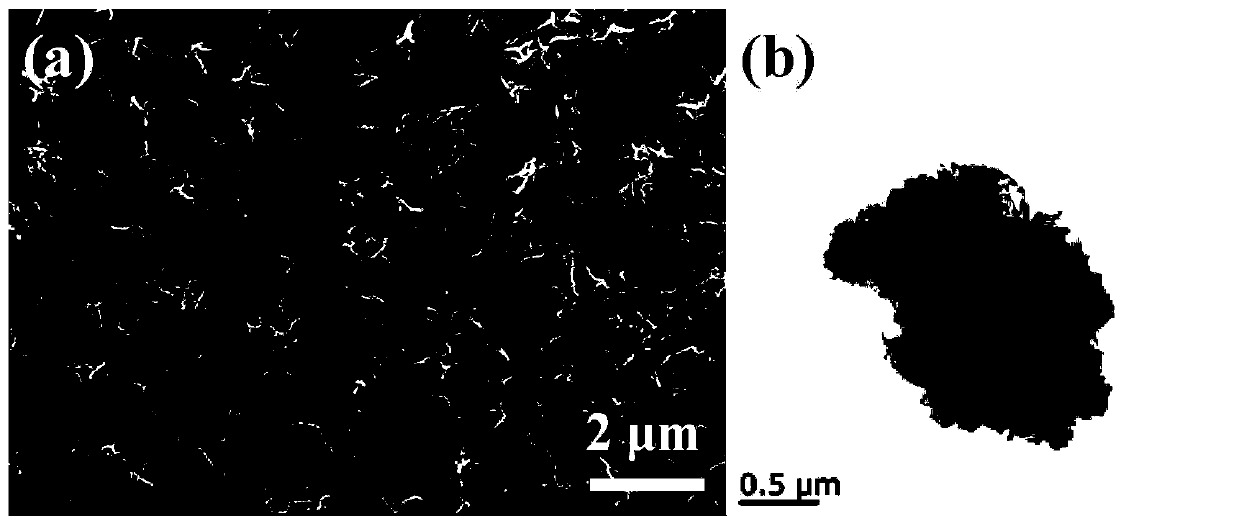

[0045] A kind of preparation and performance research of MnCo-LDH / C / NiMn-LDH composite electrode material based on nickel foam, comprising the following steps:

[0046] (1) Uniformly dissolve manganese nitrate tetrahydrate, cobalt nitrate hexahydrate, urea, and ammonium fluoride in 70 mL of deionized water to obtain dispersion 1. The amount of manganese nitrate tetrahydrate substance in the solution is 3.5mmol, the amount of cobalt nitrate hexahydrate substance is 3.5mmol, the amount of urea substance is 21mmol, and the amount of ammonium fluoride substance is 14mmol;

[0047] (2) Transfer the dispersion liquid 1 prepared in step (1) to a reaction kettle, put nickel foam (2cm×2cm), and conduct a hydrothermal reaction at 130° C. for 14 hours. The obtained MnCo-LDH based on nickel foam was rinsed three times with deionized water and ethanol respectively, and dried at 60°C for 8h;

[0048] (3) Soak the MnCo-LDH based on foamed nickel obtained in step (2) in glucose solution for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com