Nano-vacuum gap breakdown characteristic experimental device and method based on FIB-SEM two-beam system

A FIB-SEM and experimental device technology, applied in the field of experimental research systems, can solve the problem that optical microscopes cannot meet the resolution requirements and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below:

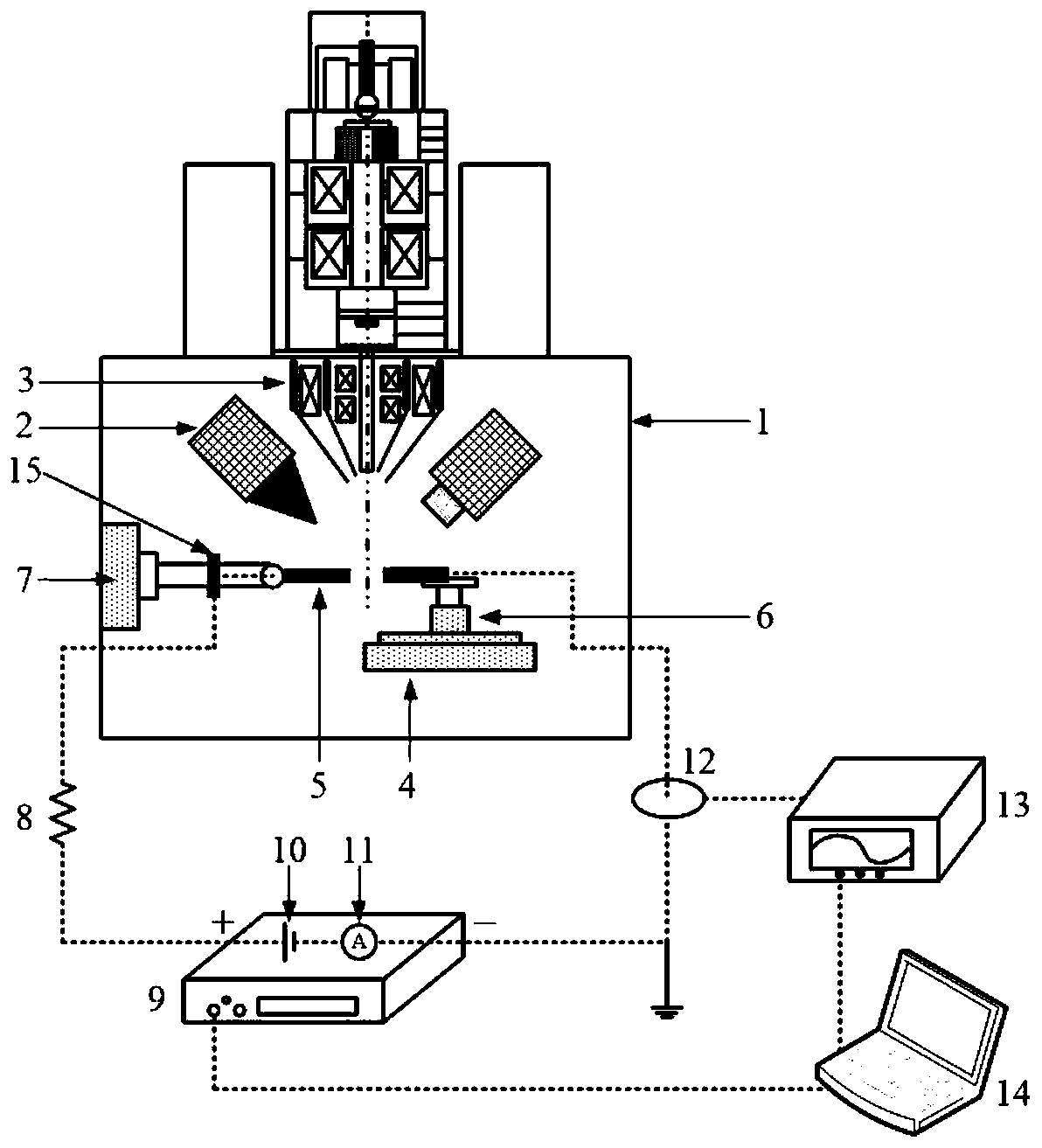

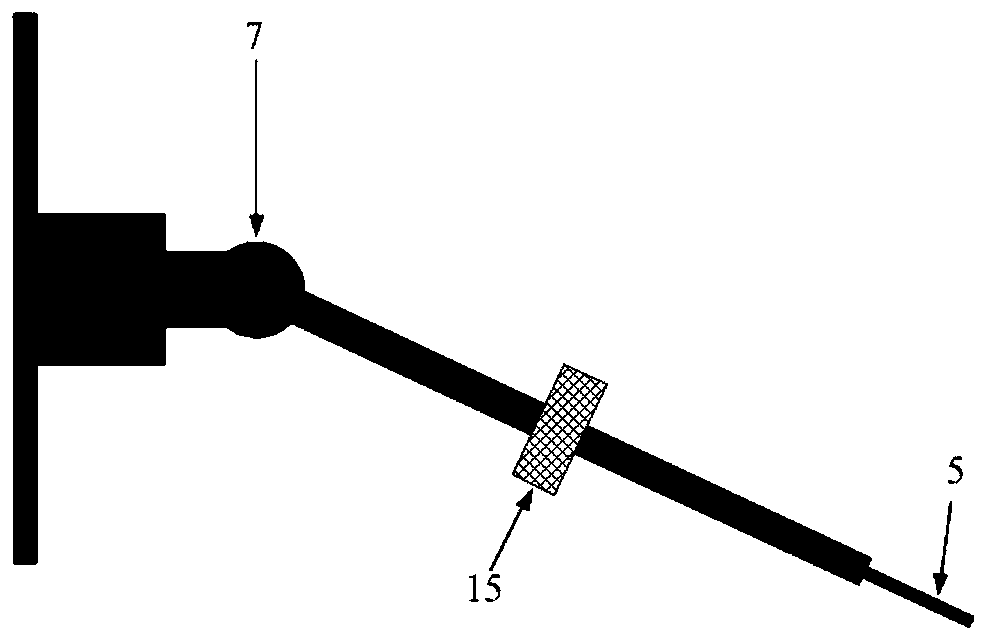

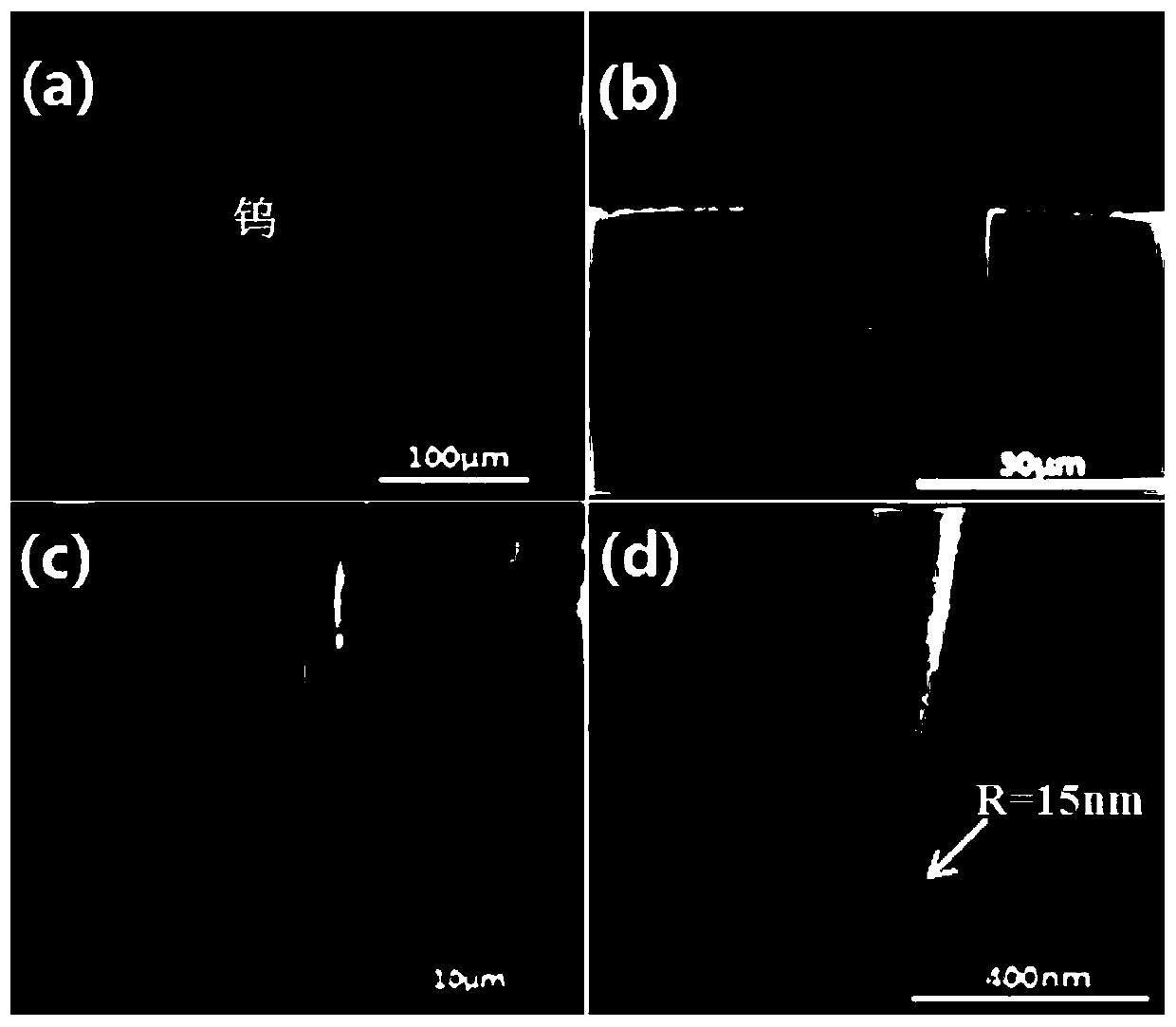

[0031] The nano-vacuum gap breakdown characteristics experimental device based on the FIB-SEM dual-beam system, including the FIB-SEM dual-beam system 1, the experimental chamber of the FIB-SEM dual-beam system 1 is equipped with a micro-nano scale electrode system 4, a micro-nano scale The nanomanipulator 7 and the five-axis sample stage 6 of the electrode system 4 are respectively connected to a test electrode 5, and the two test electrodes 5 are respectively connected to the voltage and current test circuit 9 through a current limiting resistor 8 and a pulse current sensor 12, and the pulse current sensor 12 Pass through the voltage and current test circuit 9 and connect with the oscilloscope 13, and the oscilloscope 13 and the voltage and current test circuit 9 are connected with the computer 14 to record the test data.

[0032]The FIB-SEM dual-beam system 1 is Helios Nanolab 600i model of FEI Company, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com