Exclude Thermal Shock Safety Valve

A safety valve and heat removal technology, applied in the field of safety valves, to solve the problem of thermal shock stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

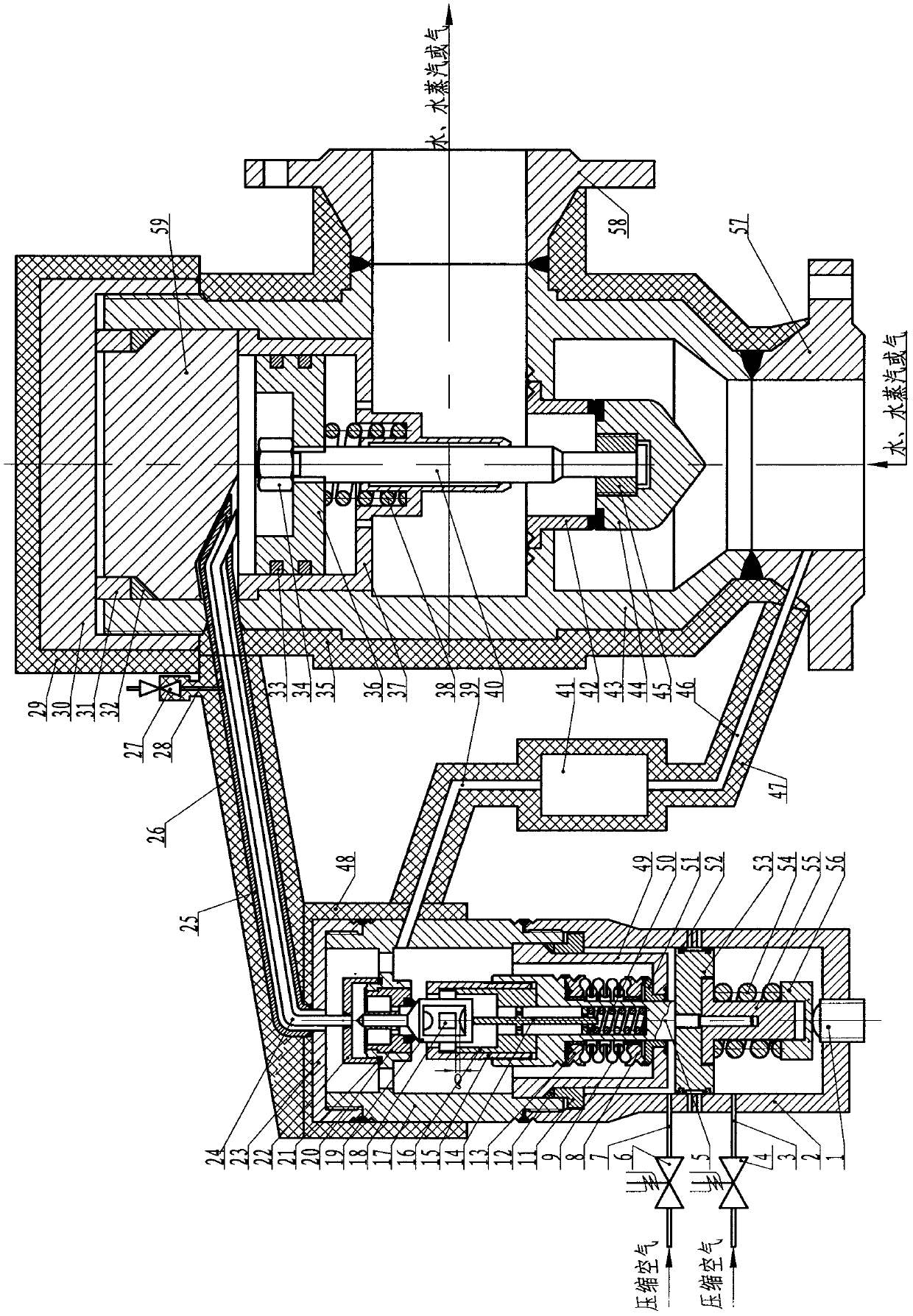

[0015] The thermal shock elimination safety valve provided by the present invention is composed of a main valve, an auxiliary valve, a thermal insulation sleeve, a filter, an air release valve, a solenoid valve and a pulse tube. The main valve seat 42 is fastened in the main valve body 43 and sealed by welding. The main valve disc 44 is covered on the main valve seat 42. The lower end of the main valve stem 40 is screwed in by the screw plug 45 so that it is in contact with the main valve body. Petal 44 links to each other, and the upper end passes piston 36, and with nut 34, is screwed on the main valve piston 36, and main valve piston 36 is placed in the cylinder liner 37. The main valve preload spring 38 is placed in the groove of the cylinder liner 37, the upper end is in contact with the main valve piston 36, and the lower end is in contact with the bottom of the groove of the cylinder liner 37, and is compressed to a certain extent. The force generated by the compression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com