A transient shock wave temperature measurement system and method

A temperature measurement, shock wave technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

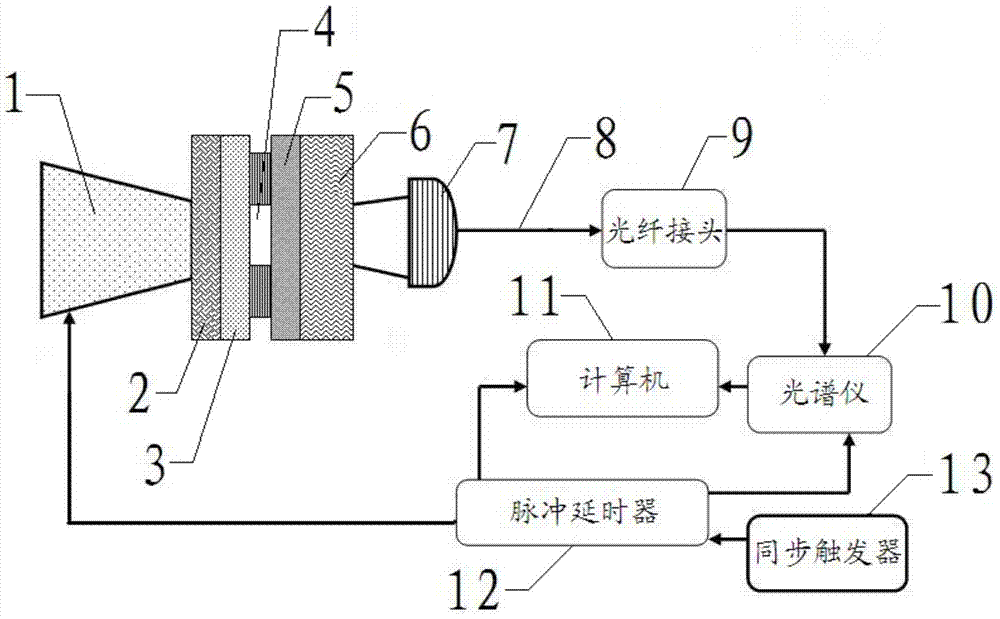

[0034] Such as figure 1 As shown, the shock wave of the measured temperature is generated by the transient shock wave generating device, which includes a laser driver 1, a flyer target 3, a vacuum chamber 4, a metal target 5, and a LiF window 6 connected in sequence, wherein the flyer An ablation layer 2 is provided on the side of the target 3 close to the laser driver 1 .

[0035] A kind of transient shock wave temperature measurement system provided by the present invention comprises the signal collector 7 arranged outside the LiF window 6 of the transient shock wave generating device (the side away from the metal target 5), connected to the signal collector 7 through an optical fiber 8 Optical fiber joint 9, connect the spectrometer 10 of optical fiber joint 9, connect the computer 11 of spectrometer 10, respectively connect the pulse delay device 12 of laser driver 1 in spectrometer 10, computer 11, transient shock wave generation device, connect pulse delay device 12 Syn...

Embodiment 2

[0040] Transient shock wave temperature measurement system with laser velocity interferometer (also can be considered as "complete equation of state experimental diagnosis system for transient shock wave temperature measurement")

[0041] Such as figure 2 As shown, the transient shock wave temperature measurement system provided by the present invention, in conjunction with the laser velocity interferometer (in this embodiment, the laser velocity interferometer 16 is an imaging laser velocity interferometer VISAR), can simultaneously obtain the kinematic parameters and thermodynamic parameters of the material. Parameter (the described material is the inner material used to generate shock waves and emit thermal radiation light arranged in the transient shock wave generating device, i.e. metal target 5), thereby obtaining a complete equation of state, the specific scheme is:

[0042] The shock wave of the measured temperature is generated by a transient shock wave generating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com