Supporting leg hydraulic system and engineering machinery

A hydraulic system and outrigger technology, applied in mechanical equipment, fluid pressure actuating devices, vehicle maintenance, etc., can solve problems such as high ground requirements and inability to perform operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

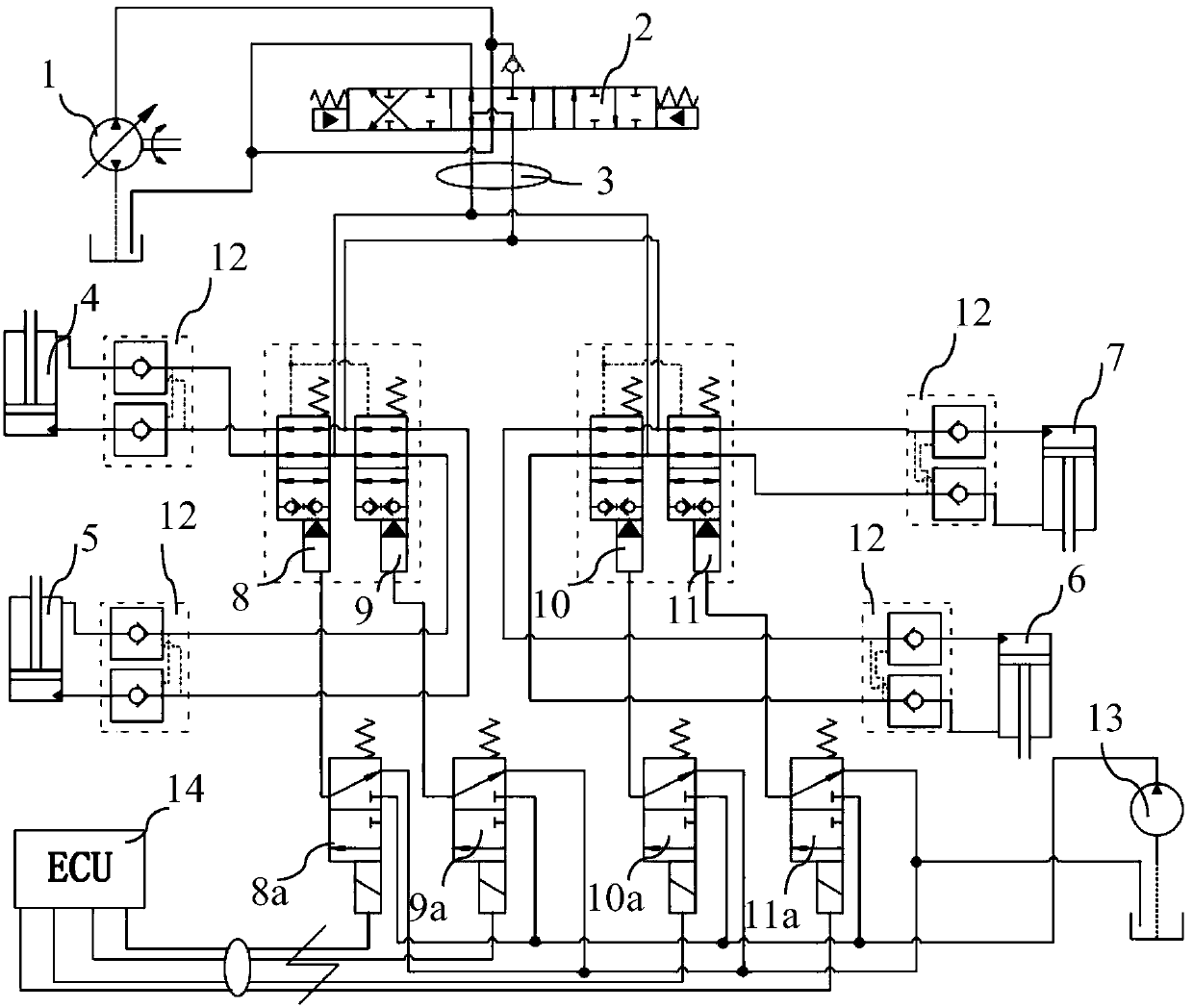

[0032] Please refer to figure 1 , is a schematic diagram of the outrigger hydraulic system according to an embodiment of the present invention.

[0033] In an embodiment of the outrigger hydraulic system disclosed in the present invention, it can be used in excavators, such as figure 1 As shown, it includes a main pump 1, a main valve 2 and four driving cylinders, wherein the main valve 2 is a three-position eight-way electromagnetic reversing valve (it can also be a three-position four-way or a three-position six-way, depending on needs, It is not used to limit the present invention), the four driving cylinders are respectively the first cylinder 4, the second cylinder 5, the third cylinder 6 and the fourth cylinder 7, and the four cylinders can respectively drive a leg to expand and contract.

[0034] After the oil cylinder drives the legs to stretch out, it needs to be maintained to lock the position of the oil cylinder. A hydraulic lock 12 is also installed on the pipelin...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that the four switching valves are normally open two-position two-way on-off valves, which can be electromagnetic valves or hydraulic control valves, preferably hydraulic control valves. The four on-off valves are respectively Connect to the main oil circuit of four oil cylinders, preferably connect to the main oil circuit of the rod chamber of the four oil cylinders, and directly connect the main oil circuit of the rodless chamber to the main valve 2 through the central rotary joint 3, and the other components remain unchanged.

[0056] In this embodiment, its control principle is similar to that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com