Fiber-reinforced thermoplastic resin member welding method and welding device

A thermoplastic resin and a joining method technology, which are applied in the fields of joining and joining devices for fiber-reinforced thermoplastic resin parts, and can solve the problems of high temperature and poor appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0044] An example of the method for joining fiber-reinforced thermoplastic resin parts and the device for joining fiber-reinforced thermoplastic resin parts according to the first embodiment will be described.

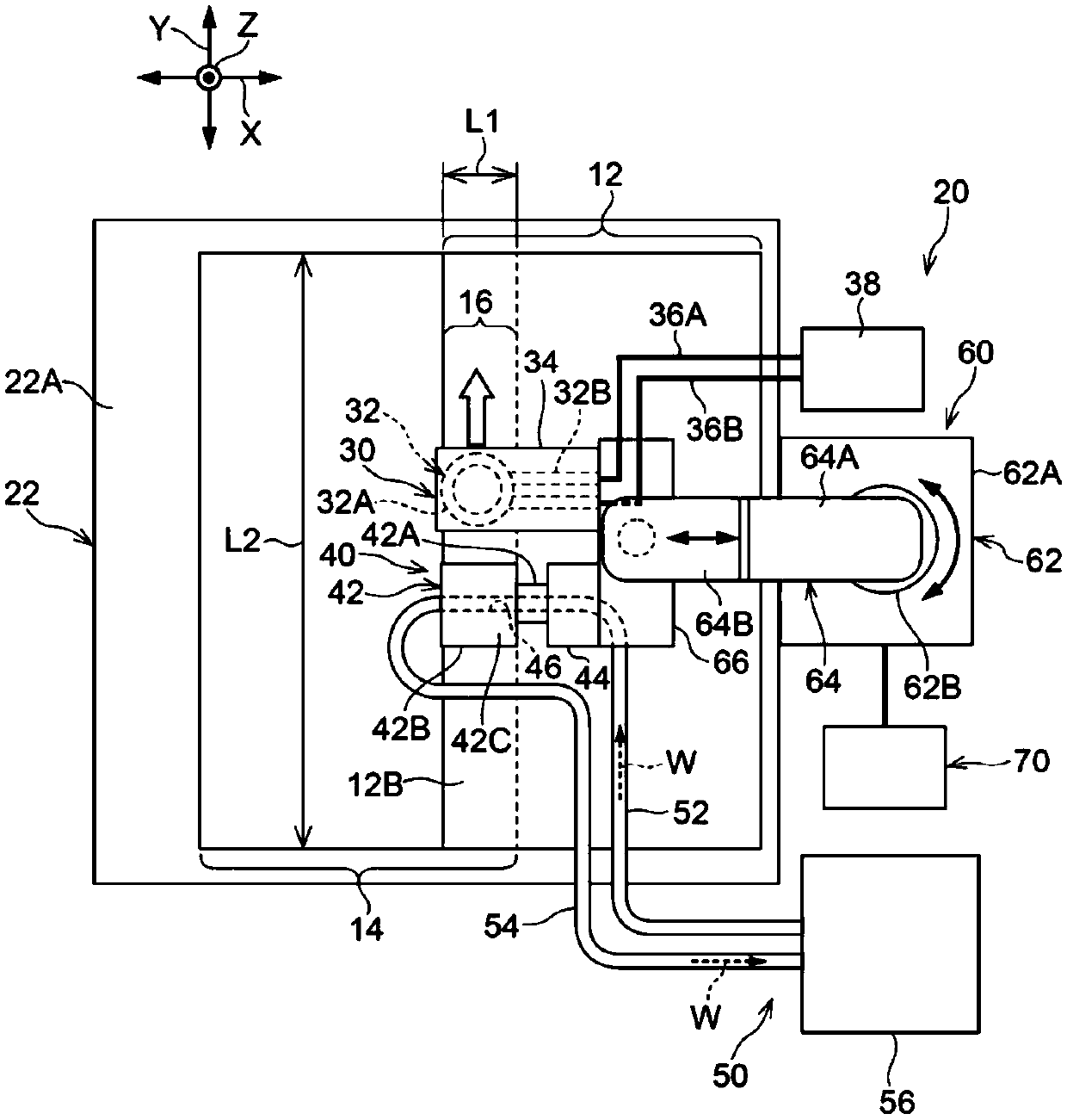

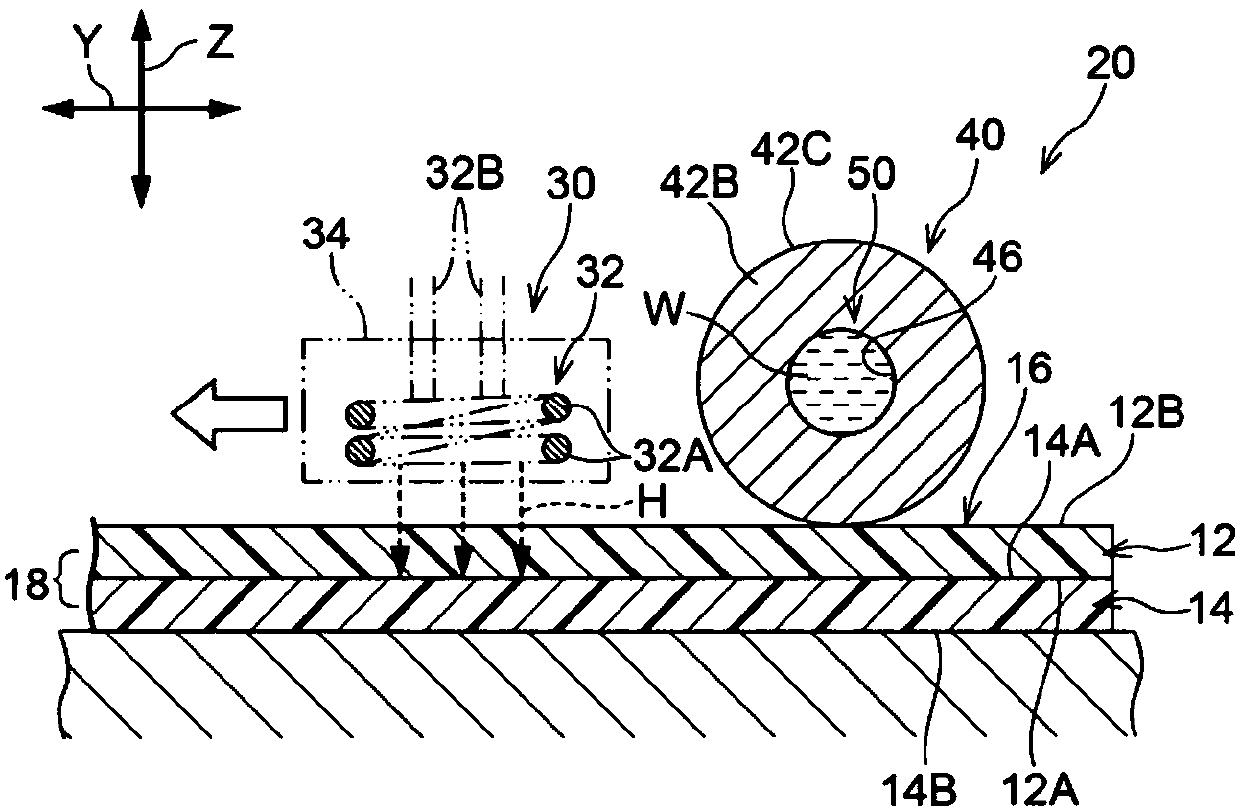

[0045] the whole frame

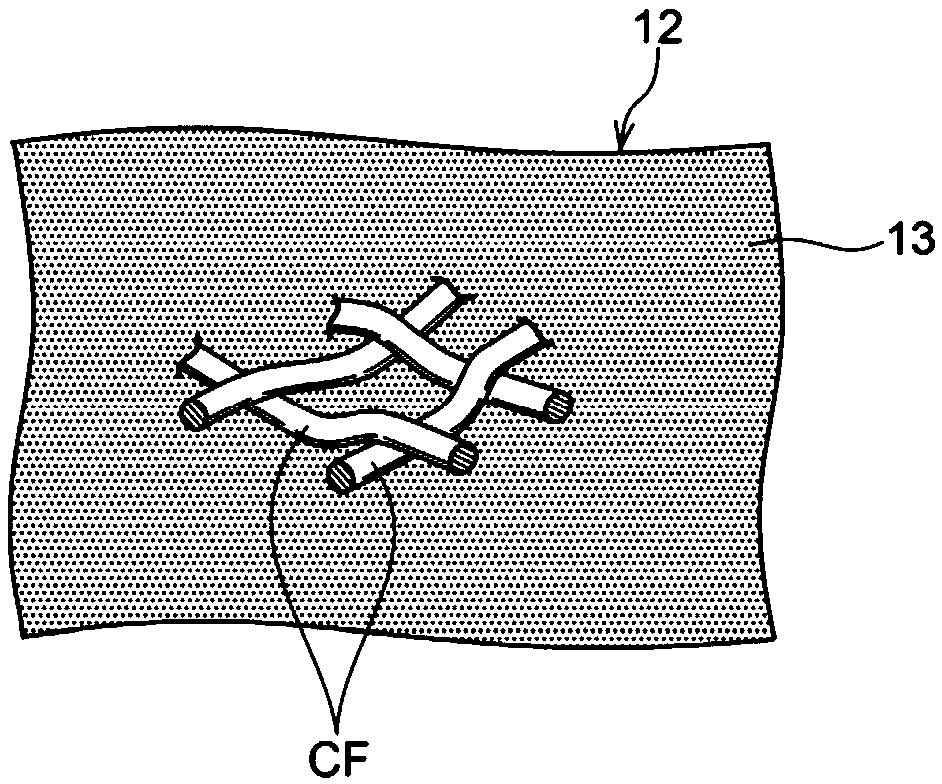

[0046] exist figure 1 In , a bonding device 20 for bonding the resin component 12 and the resin component 14 is shown. The resin member 12 and the resin member 14 are examples of a plurality of fiber-reinforced thermoplastic resin members. The joining device 20 is an example of a joining device for fiber-reinforced thermoplastic resin components. In addition, as an example, the resin member 12 and the resin member 14 are set to be members having the same shape, size, and composition. Therefore, the resin member 12 will be described, and the description of the resin member 14 will be omitted.

[0047] As an example, the resin member 12 is set as a plate material formed into a rectangular shape when viewed from above. In the following descri...

no. 2 approach

[0099] Next, an example of a method for joining fiber-reinforced thermoplastic resin components and a device for joining fiber-reinforced thermoplastic resin components according to the second embodiment will be described. In addition, about components and locations that are basically the same as those in the first embodiment described above, the same reference numerals as those in the first embodiment will be assigned and descriptions thereof will be omitted.

[0100] exist Figure 6 In , the engagement device 80 of the second embodiment is shown. The joining device 80 is an example of a joining device for fiber-reinforced thermoplastic resin components. Furthermore, as an example, the joining device 80 has a heating part 30 , a pressurizing part 90 , a support roller 82 , and a cooling part 50 . The pressurizing part 90 is an example of a pressurizing part. In addition, in the bonding apparatus 80, the mounting table 22 and the moving part 60 are not provided (refer to f...

no. 3 approach

[0110] Next, an example of a method for joining fiber-reinforced thermoplastic resin parts and an apparatus for joining fiber-reinforced thermoplastic resin parts according to the third embodiment will be described. In addition, about the components and parts which are basically the same as those in the above-mentioned first and second embodiments, the same symbols as those in the first and second embodiments are given, and description thereof will be omitted.

[0111] exist Figure 7 In , the joining device 100 of the third embodiment is shown. The joining device 100 is an example of a joining device for fiber-reinforced thermoplastic resin components. In addition, as an example, the joining device 100 is configured such that, in the joining device 20 of the first embodiment (refer to figure 1 ), instead of the cooling unit 50 (see figure 1 ) and a cooling unit 110 is provided. In addition, in Figure 7 In, the storage part 34 and the power supply 38 are omitted (refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com