pneumatic tire

A technology of pneumatic tires and tires, applied in pneumatic tires, reinforcement layers of pneumatic tires, special tires, etc., can solve the problem that the improvement effect of tire lightweight driving stability may not be sufficient, and achieve lightweight and driving stability. The effect of improving driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

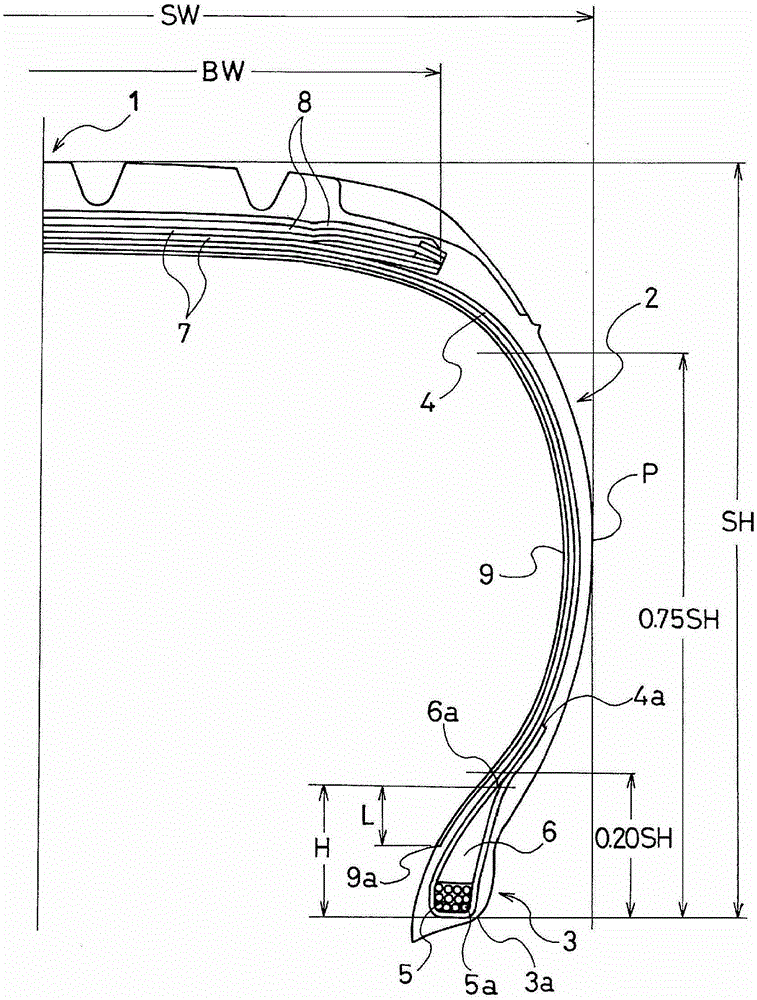

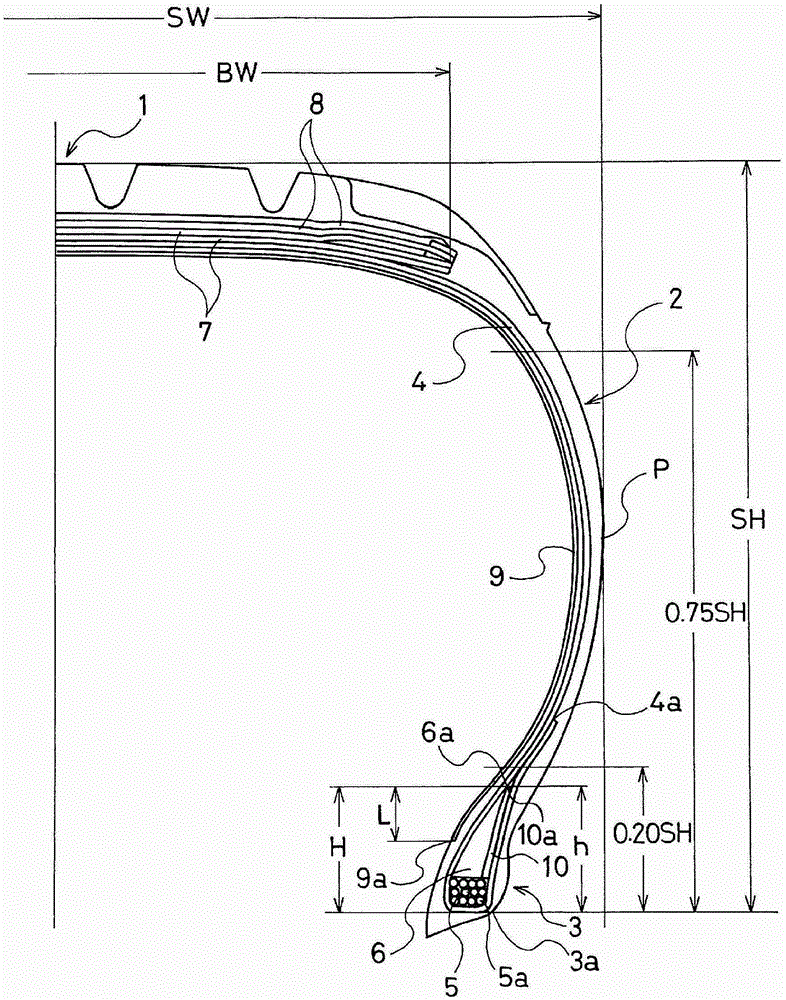

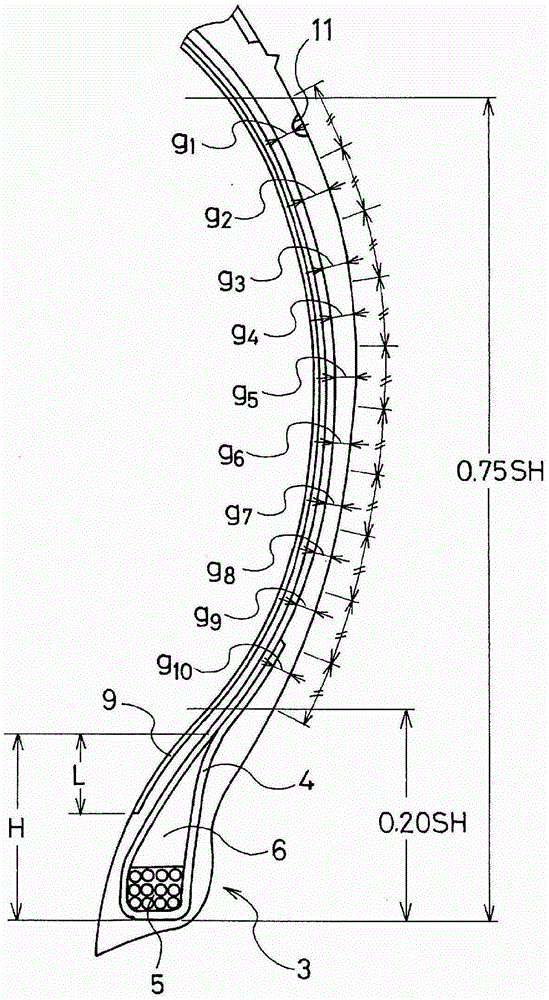

[0058] Make the tire size 195 / 65R15, make the Young’s modulus of the inner liner, the thickness of the inner liner, the height H of the bead filler from the tire heel, the cross-sectional area of the bead filler, and the shape of the bead filler , the deviation distance from the end of the carcass layer to the maximum tire width position, the deviation distance from the end of the carcass layer to the end of the bead filler, the overlapping amount of the inner liner and the bead filler, and the average rubber thickness of the sidewall , the line spacing of the bead core, the presence or absence of a reinforcing layer between the bead filler and the carcass layer, the tanδ of the sidewall rubber, and the ratio BW / SW of the tire section width SW to the tire maximum belt width BW 21 kinds of tires of Conventional Example 1, Comparative Example 1, and Examples 1-19 as shown in Tables 1-4 were determined.

[0059] It should be noted that, for the offset distance from the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com