5083 aluminum alloy laser welding process method

A process method and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of large heat input, achieve the effect of small heat input, overcome large heat input, and reduce temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

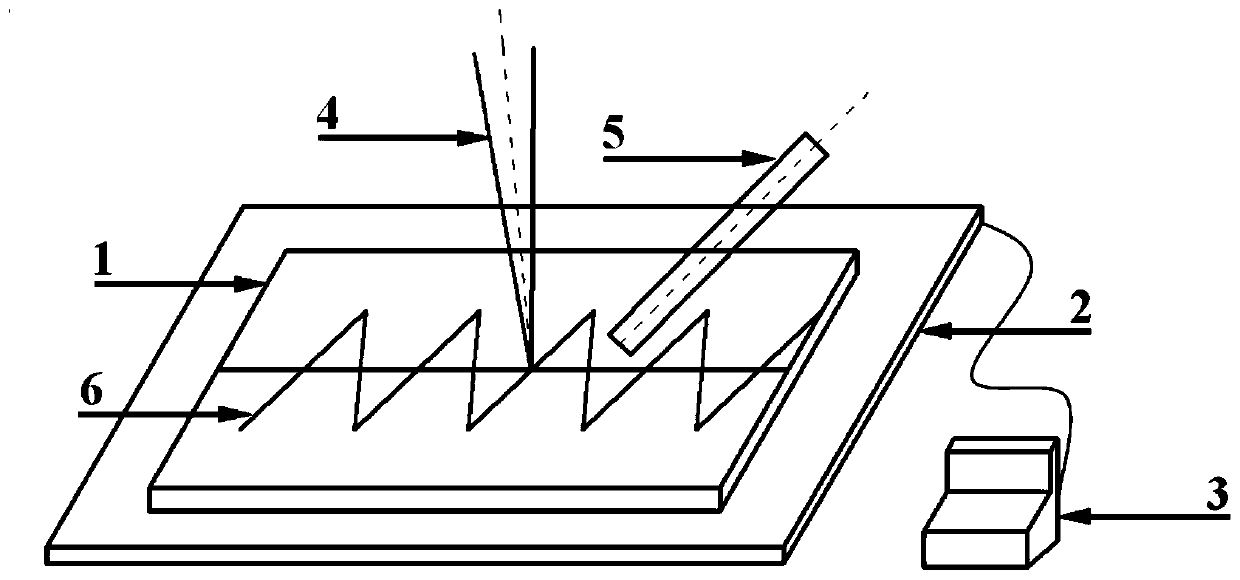

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] A 5083 aluminum alloy laser welding process, the welding method is realized based on the following structure, the pretreated 5083 aluminum alloy workpiece 1 is fixed on the preheated substrate 2, the angle between the pulse laser 4 and the vertical direction is adjusted to 5°, and the protection The air nozzle 5 has an included angle of 45° with the vertical direction, and the temperature controller 3 is turned on and adjusted to a certain temperature.

[0026] Specific steps are as follows:

[0027] S1: Before welding, use 600# sandpaper to remove the oxide skin within 30mm around the 5083 aluminum alloy butt weld until the metal luster is exposed around the weld, then wipe it with acetone and dry it.

[0028] S2: Fix the surface-treated 5083 aluminum alloy on the preheated substrate. Turn on the temperature controller an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com