Production method for controlling head and tail performance differences of TMCP-type steel plates

A production method and technology for steel plates, applied in the field of metallurgy, can solve the problems of increasing the sampling and inspection frequency of the head and tail, reducing the length allowance of the steel plate, and unstable performance of the steel plate, so as to improve the performance difference, the equipment investment is less, and the design requirements are low. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

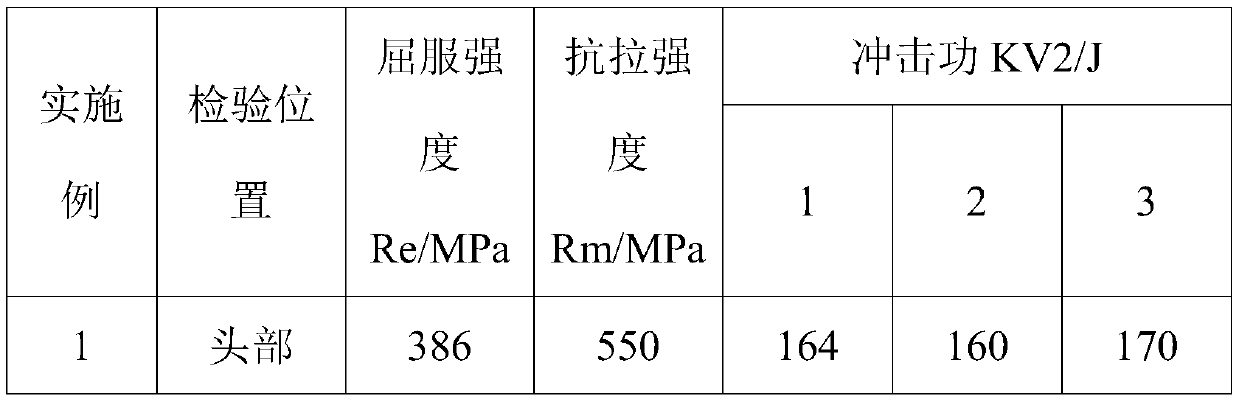

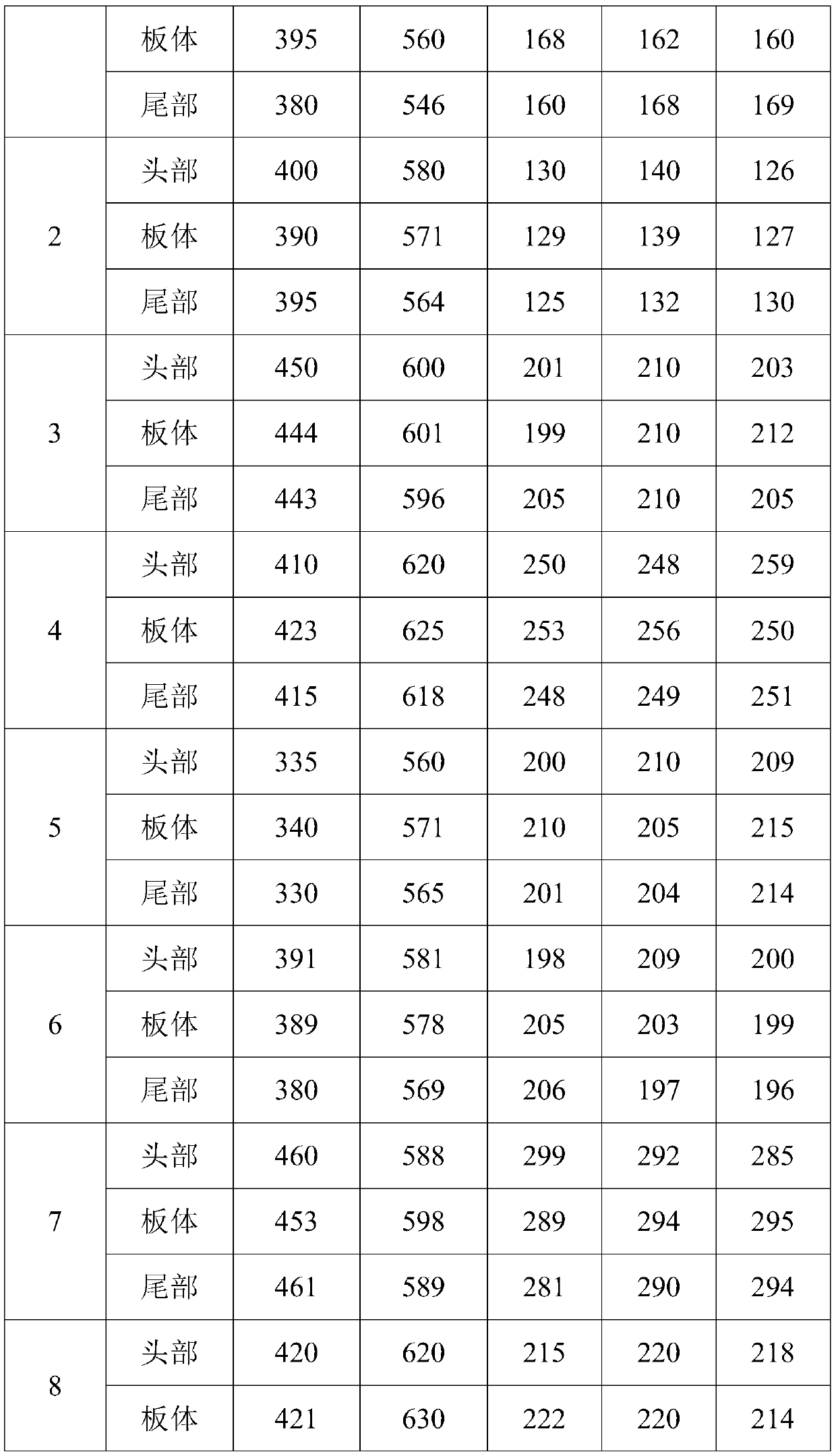

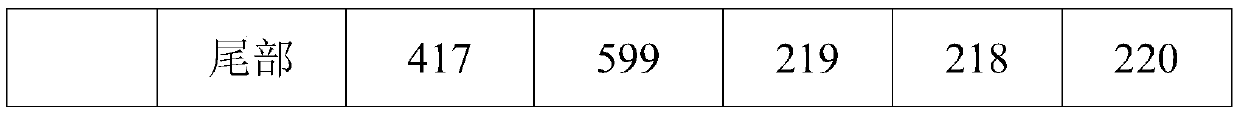

Examples

Embodiment 1

[0016] This embodiment is the production method of TMCP type Q345qD steel plate, the rolling specification is 8*2450*10000mm, and the continuous casting slab of 200*1500 type is adopted.

[0017] The production method of the present embodiment TMCP type Q345qD steel plate comprises billet heating process, rolling process, post-rolling cooling process, and concrete process step is as follows:

[0018] (1) Heating process: the temperature of the billet heating section is 1210°C, the temperature of the soaking section is 1200°C; the distance between the two sides of the billet is 1.1m, and the distance between the head and tail of the billet is 1.5m;

[0019] (2) Rolling process: during rolling, the steel is aired with natural repeated swings, and the roll speed is 2.5m / s; before the finishing rolling stage, a water descaling is performed, and the high-pressure dephosphorization water pressure is 20MPa, and the dephosphorization nozzle and the steel surface are inclined at an angl...

Embodiment 2

[0023] This embodiment is the production method of TMCP type X52MS steel plate, the rolling specification is 24*2750*9000 mm, and the continuous casting slab of 200*1500 type is used.

[0024] The production method of the TMCP type X52MS steel plate of this embodiment comprises a billet heating process, a rolling process, and a post-rolling cooling process, and the specific process steps are as follows:

[0025] (1) Heating process: the temperature of the billet heating section is 1215°C, the temperature of the soaking section is 1210°C; the distance between the two sides of the billet is 1.0m, and the distance between the head and tail of the billet is 1.6m;

[0026] (2) Rolling process: during rolling, the steel is aired with natural repeated swings, and the roll speed is 2.0m / s; before the finishing rolling stage, a water descaling is performed, and the high pressure dephosphorization water pressure is 21MPa, and the dephosphorization nozzle and the steel surface are incline...

Embodiment 3

[0030] This embodiment is the production method of TMCP type Q390GJE steel plate, the rolling specification is 80*3100*7500mm, and the continuous casting slab of 300*1800 type is adopted.

[0031] The production method of the TMCP type Q390GJE steel plate of this embodiment comprises a steel billet heating process, a rolling process, and a post-rolling cooling process, and the specific process steps are as follows:

[0032] (1) Heating process: the temperature of the billet heating section is 1230°C, the temperature of the soaking section is 1215°C; the distance between the two sides of the billet is 1.4m, and the distance between the head and tail of the billet is 2.0m;

[0033] (2) Rolling process: during rolling, the steel is aired with natural repeated swings, and the roll speed is 1.7m / s; before the finishing rolling stage, a line of water is used for descaling, and the high pressure dephosphorization water pressure is 25MPa, and the angle of inclination between the dephos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com