A kind of molybdenum disulfide supported IR single-atom catalyst and its preparation method and application

A molybdenum disulfide catalyst technology, applied in the field of molybdenum disulfide-supported Ir single-atom catalysts and its preparation, can solve the problems of poor transition metal H activation ability, limited wide application, harsh reaction conditions, etc., to reduce the content of precious metals, The effect of large specific surface area and high loading concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

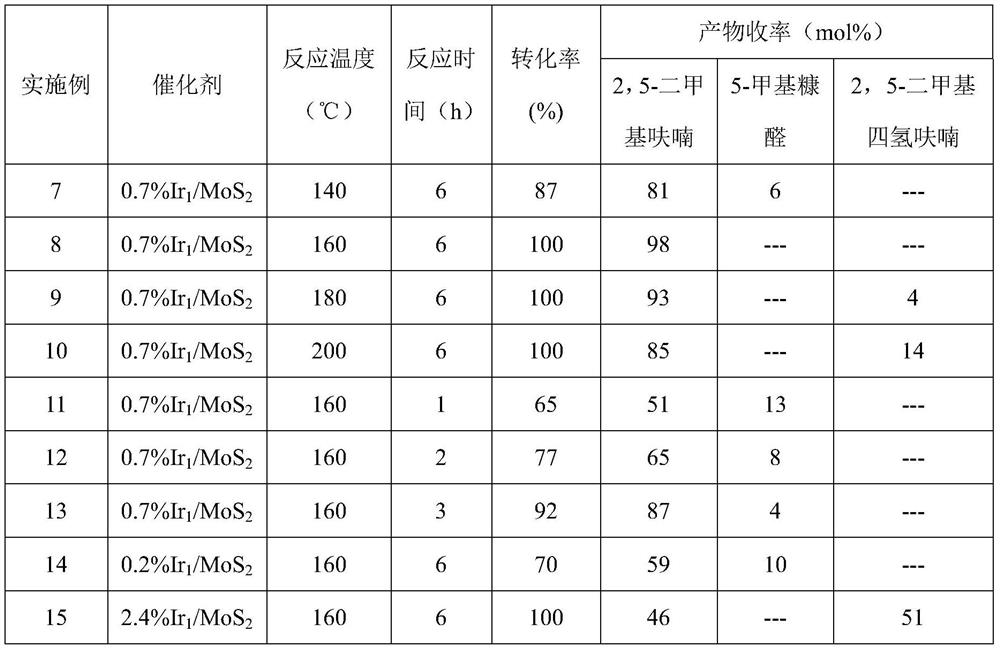

Examples

Embodiment 1

[0027] Dissolve 0.12g of sulfur powder in 50mL of oleylamine and stir magnetically for 20min to obtain a sulfur source precursor; dissolve 0.32g of ammonium molybdate tetrahydrate and 0.0023g of chloroiridic acid in 3mL of water and mix to obtain solution 1; 1 part of the solution was added dropwise to 50 parts by volume of the sulfur source precursor, and stirred rapidly at 20-30°C for 1 hour; then transferred to a 100mL stainless steel reaction kettle, and the temperature was raised to 220°C at 5°C / min for 48h. Subsequently, it was centrifuged and filtered, and washed several times with ethanol and cyclohexane until the ligand oleylamine on the surface of the catalyst was washed off to obtain a black solid, and the collected black solid was vacuum-dried for 10 hours. Reduction at 300°C for 1 hour in a hydrogen atmosphere to obtain 0.2% Ir 1 / MoS 2 catalyst.

Embodiment 2

[0029] Add 0.12g of sulfur powder to 50mL of oleylamine and stir at room temperature for 20min to obtain a sulfur source precursor; dissolve 0.32g of ammonium molybdate tetrahydrate and 0.008g of chloroiridic acid in 3mL of water and mix to obtain solution 1; The solution 1 was added dropwise to 50 parts by volume of the sulfur source precursor, and stirred rapidly at 20-30°C for 1 hour; then transferred to a 100mL stainless steel reaction kettle, and heated at 5°C / min to 220°C for 48 hours. Subsequently, it was centrifuged and filtered, and washed several times with ethanol and cyclohexane until the ligand oleylamine on the surface of the catalyst was washed off to obtain a black solid, and the collected black solid was vacuum-dried for 10 hours. Reduction at 300°C for 1 hour in a hydrogen atmosphere to obtain 0.7% Ir 1 / MoS 2 catalyst.

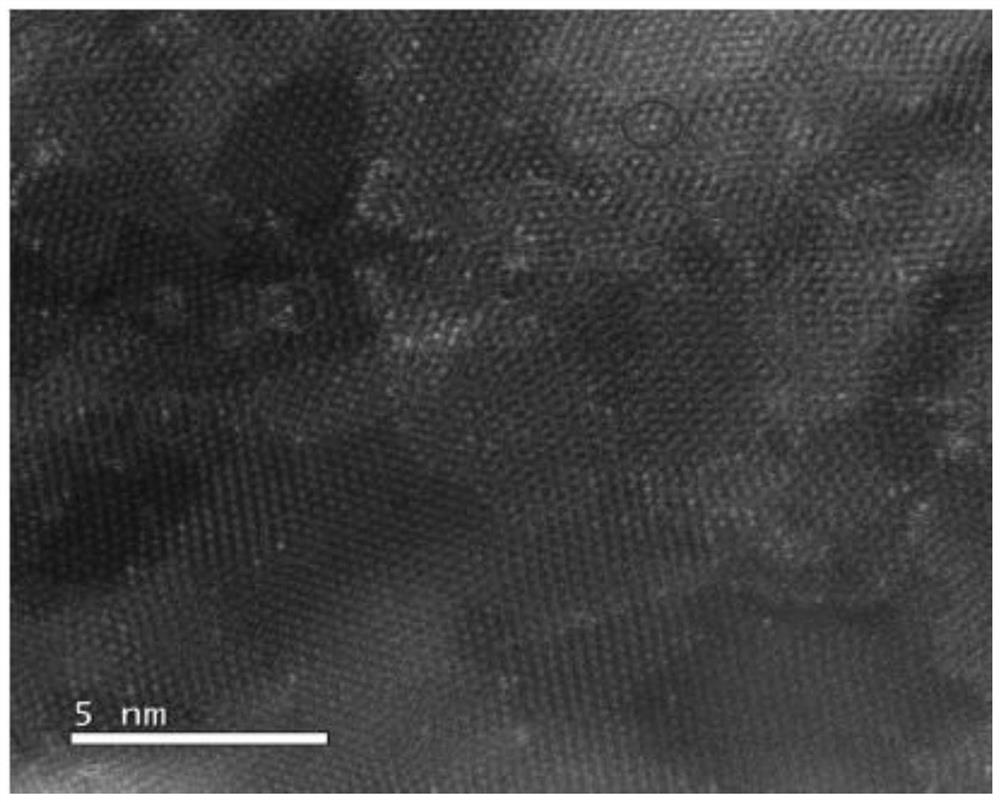

[0030] The catalyst was photographed with a high-power transmission electron microscope, such as figure 1 shown, from figure 1 It can b...

Embodiment 3

[0032]Add 0.12 g of sulfur powder to 50 mL of oleylamine and stir at room temperature for 20 minutes to obtain a sulfur source precursor; dissolve 0.32 g of ammonium molybdate tetrahydrate and 0.024 g of chloroiridic acid in 3 mL of water and mix to obtain solution 1; The solution 1 was added dropwise to 50 parts by volume of the sulfur source precursor, and stirred rapidly at 20-30°C for 1 hour; then transferred to a 100mL stainless steel reaction kettle, and heated at 5°C / min to 220°C for 48 hours. Subsequently, it was centrifuged and filtered, and washed several times with ethanol and cyclohexane until the ligand oleylamine on the surface of the catalyst was washed off to obtain a black solid, and the collected black solid was vacuum-dried for 10 hours. 2.1% Ir / MoS was obtained by reduction at 300°C for 1 h in a hydrogen atmosphere 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com