Coating film for positive and negative plate of high-rate lead-acid storage battery and preparation method

A lead-acid battery, positive and negative plate technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of unsatisfactory high-rate performance, poor film quality, and high film density, and improve high-rate performance. , The effect of reasonable component configuration and moderate density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

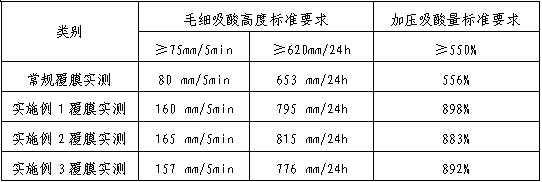

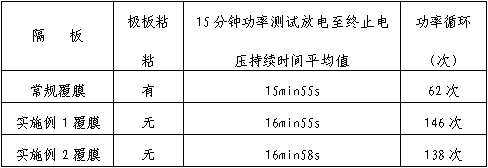

Embodiment 1

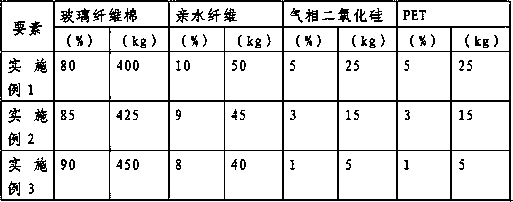

[0034] A film preparation method for positive and negative electrodes of high-rate lead-acid batteries, the method is carried out according to the following steps:

[0035] 1. Measure the raw materials according to the component configuration table of the embodiment, including 400kg of glass fiber cotton, 50kg of hydrophilic fiber, 25kg of fumed silica and 25kg of PET. The diameter of the glass fiber cotton used in this example is 0.5 μm, the diameter of the hydrophilic fiber is 10 μm, the content of fumed silica is 99.9%, and the surface area of PET is 175m 2 / g, the primary particle size is 10nm, and the diameter is 20μm. Put the measured raw materials into the material tank of the disperser, then inject deionized water into the material tank, turn on the disperser and disperse at a speed of 1500r / min for 1.5h, so that the raw materials are evenly dispersed, and the prepared raw slurry spare.

[0036] 2. Dilute the original slurry

[0037] Take the original slurry, and ...

Embodiment 2

[0049] A film preparation method for positive and negative plates of high-rate lead-acid batteries, the method is carried out according to the following steps:

[0050] 1. Measure the raw materials according to the component configuration table of the embodiment, including 425kg of glass fiber cotton, 45kg of hydrophilic fiber, 15kg of fumed silica and 15kg of PET. The diameter of glass fiber cotton used in this example is 1.0 μm, the diameter of hydrophilic fiber is 15 μm, the content of fumed silica is 99.9%, and the surface area of PET is 200m 2 / g, the primary particle size is 10nm, and the diameter is 15μm. Put the measured raw materials into the material tank of the disperser, then inject deionized water into the material tank, turn on the disperser and disperse at a speed of 1800r / min for 2 hours, so that all raw materials are evenly dispersed, and the prepared raw slurry is ready for use .

[0051] 2. Dilute the original slurry

[0052] Take the original slurry, a...

Embodiment 3

[0064] A film preparation method for positive and negative plates of high-rate lead-acid batteries, the method is carried out according to the following steps:

[0065] 1. Measure the raw materials according to the component configuration table of the embodiment, including 450kg of glass fiber cotton, 40kg of hydrophilic fiber, 5kg of fumed silica and 5kg of PET. The diameter of the glass fiber cotton used in this example is 2.0 μm, the diameter of the hydrophilic fiber is 20 μm, the content of fumed silica is 99.8%, and the surface area of PET is 225m 2 / g, the primary particle size is 12nm, and the diameter is 20μm. Put the measured raw materials into the material tank of the disperser, then pour deionized water into the material tank, turn on the disperser and disperse at a speed of 2000r / min for 2 hours, so that all raw materials are evenly dispersed, and the prepared raw slurry is ready for use .

[0066] 2. Dilute the original slurry

[0067] Take the original slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com