A kind of internal electrode slurry for sensitive components and its preparation method

A component and internal electrode technology, which is applied in the field of internal electrode paste for multi-layer chip sensitive components and its preparation, can solve problems such as unqualified quality, decreased resistance of sensitive components, silver electromigration or ion migration, etc. , to achieve the effect of smooth and flat printed electrodes, reducing the large difference in shrinkage and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation plan

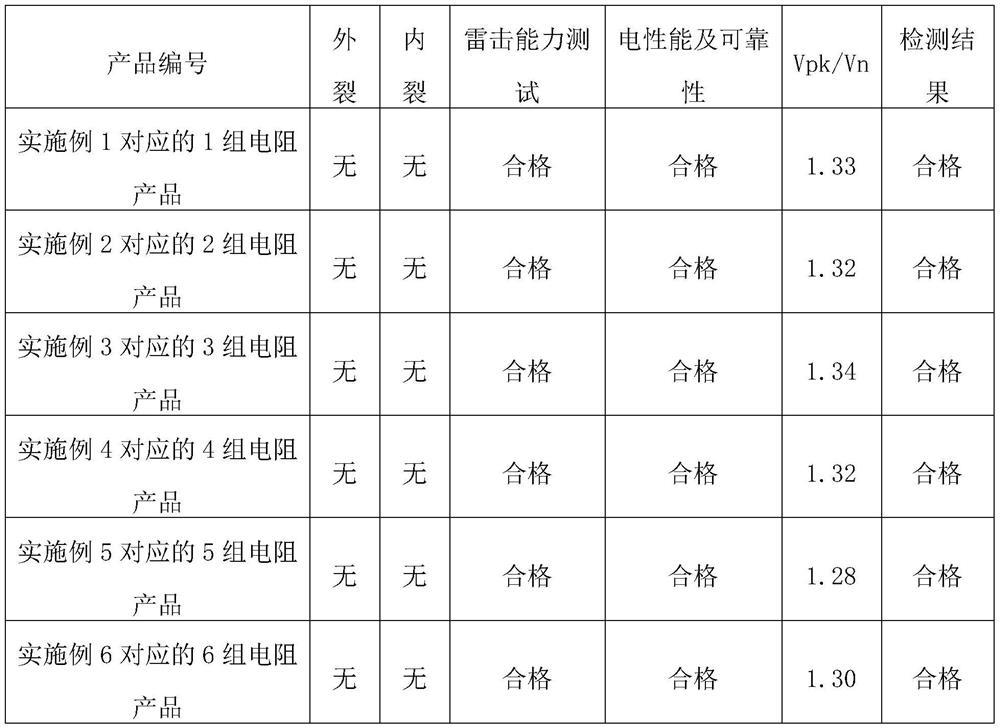

[0009] The gist of the invention is to obtain the internal electrode slurry for sensitive components with excellent performance and qualified lightning strike energy test by adjusting the reasonable ratio of conductive powder, organic carrier, organic additive and zirconia suspension and selecting suitable particle size.

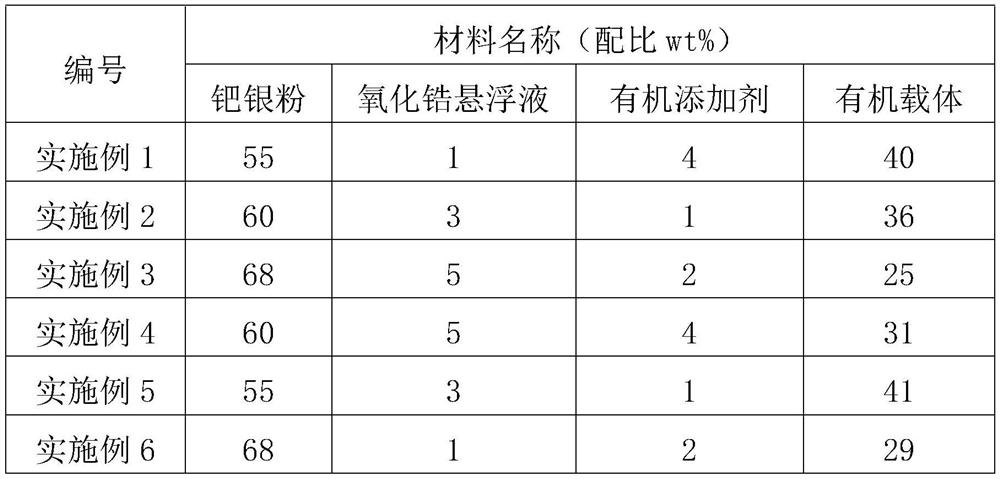

[0010] The present invention takes palladium-silver conductive powder as an example to introduce the best silver weight percent conductive powder used by different firing temperature sensitive components, and the properties of the products obtained are shown in Table 1 below.

[0011]

[0012] The formula design of the best embodiment of the present invention is as shown in Table 2. The selected one in the embodiment is the No. 2 palladium-silver conductive powder in Table 1, and silver accounts for 85% of the weight percentage of the conductive powder; Zirconia accounts for the weight percentage in the zirconia suspen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com