Method for testing particle size and particle size distribution of aluminum trihydride

A technology of aluminum hydride and particle size distribution, applied in particle size analysis, particle and sedimentation analysis, measuring devices, etc., can solve the problems of testing energetic materials safety hazards and other problems, and achieve the effect of good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

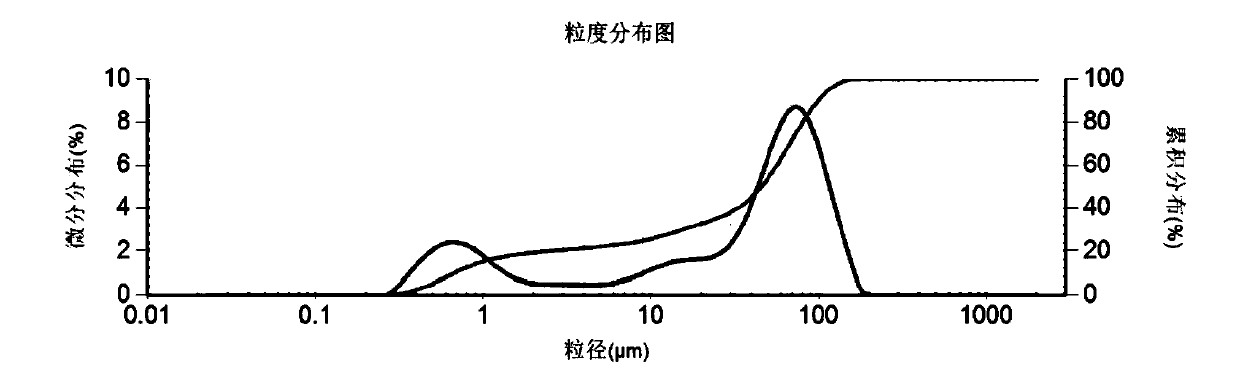

[0025] A batch of AlH 3 The particle size and particle size distribution of the sample are tested as follows: turn on the wet laser particle size analyzer, preheat for half an hour, run the particle size testing software that comes with the wet laser particle size analyzer, and clean the instrument pipeline with butyl acetate. Adjust instrument centering and test instrument background in the software window. Weigh about 1.0g of AlH 3 Put the sample in a 100mL beaker, add about 30mL of 2.5% lecithin-butyl acetate solution, and disperse it by ultrasonic (about 50Hz) for 5 minutes. The refractive index of the instrument is about 5% to 10%. Set the test parameters in the software and test the samples. After the test is completed, the computer will automatically give the test results. Particle size test results are expressed as median particle size d 50 (μm) and volume average particle size d 4,3 (μm) said. Particle size distribution diagram as figure 1 As shown, the particle...

Embodiment 2

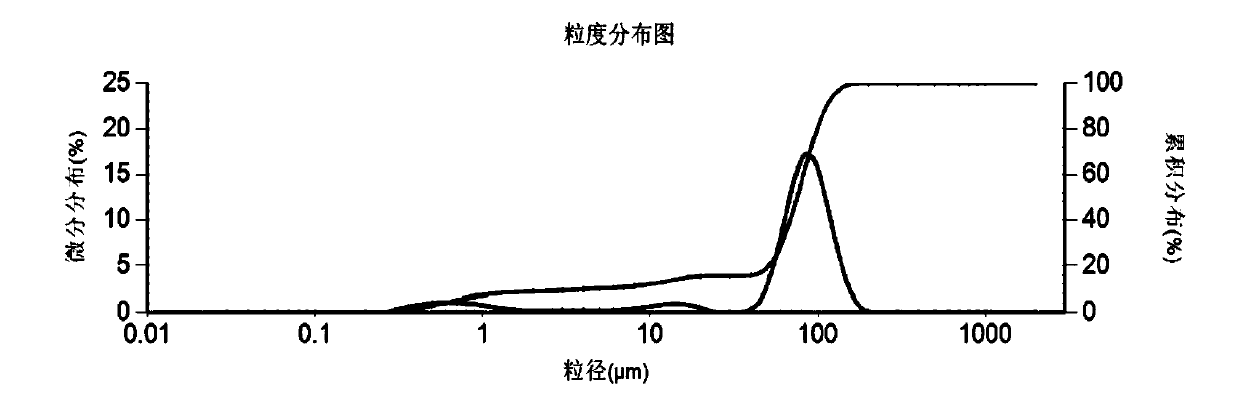

[0027] A batch of AlH 3 Samples, their particle size and particle size distribution are tested as follows: turn on the wet laser particle size analyzer and preheat for half an hour. Run the particle size test software and clean the instrument tubing with butyl acetate. Adjust instrument centering and test instrument background in the software window. Weigh about 1.0g of AlH 3 Put the sample in a 100mL beaker, add about 30mL of 2.5% wetting agent P-40 (nonylphenol polyoxyethylene ether)-butyl acetate solution, ultrasonically disperse for 5min, after the background test of the instrument is completed, add the sample solution to the In the sample pool, until the refractive index is about 5% to 10%, set the test parameters in the software and test the samples. After the test is completed, the computer will automatically give the test results. Particle size test results are expressed as median particle size d 50 (μm) and volume average particle size d 4,3 (μm) said. Particle ...

Embodiment 3

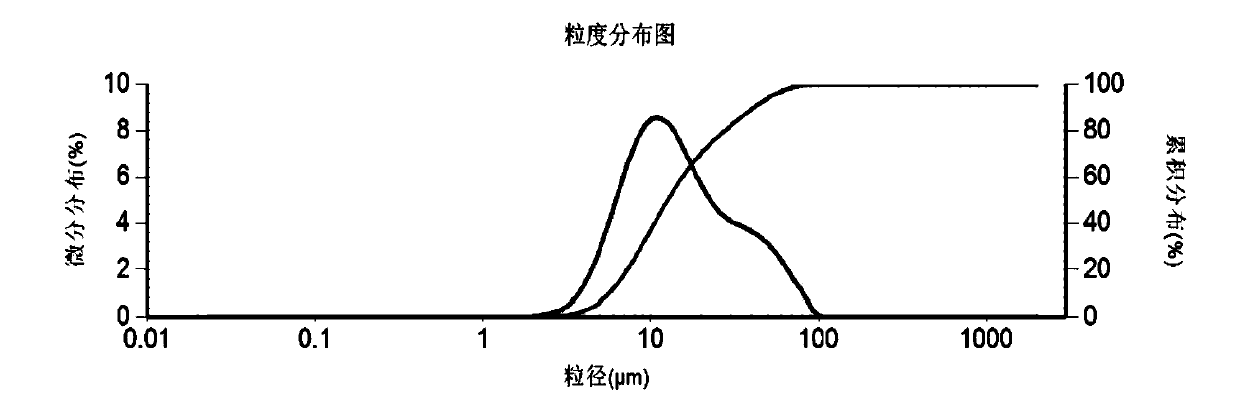

[0029] A batch of AlH 3 Samples, their particle size and particle size distribution are tested as follows: turn on the wet laser particle size analyzer and preheat for half an hour. Run the particle size test software and clean the instrument tubing with butyl acetate. Adjust instrument centering and test instrument background in the software window. Weigh about 1.0g of AlH 3 Place the sample in a 100mL beaker, add about 30mL of 2.5% lecithin-butyl acetate solution, and disperse it ultrasonically for 10 minutes. After the background test of the instrument is completed, add the sample solution into the sample cell until the refractive index is 5% to 10%. Left and right, set the test parameters in the software, test the samples, and the computer will automatically give the test results after the test is completed. Particle size test results are expressed as median particle size d 50 (μm) and volume average particle size d 4,3 (μm) said. Particle size distribution diagram a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com