A kind of preparation method of film-coated proppant for fracturing

A technology of proppant and film coating, which is applied in the field of preparation of film-coated proppant for fracturing, can solve the problem of high friction in water-carried sand pumping, and achieve the effect of simple use method and good drag reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

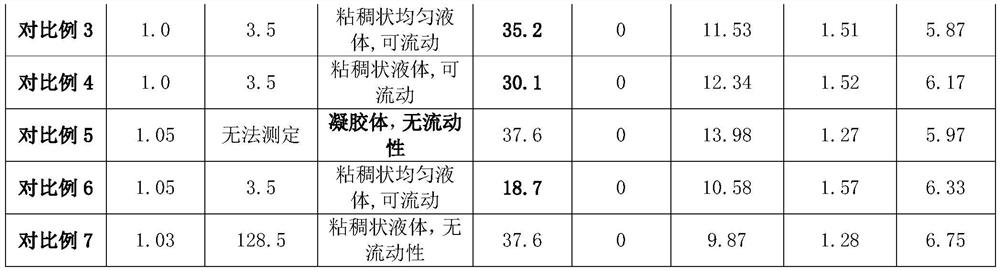

Examples

Embodiment 4

[0037] Example 4, Example 5, and Comparative Example 7 were determined according to the following descriptions.

[0038] The proppant body in the embodiment can be a fracturing proppant purchased on the market, or a resin-coated proppant prepared by using aggregate, resin and curing agent. The resin used to prepare the resin-coated proppant can be epoxy resin. Any one of resin, phenolic resin, polyurethane resin, and acrylic resin. When the resin is epoxy resin, the corresponding curing agent is amines and acid anhydrides; when the resin is phenolic resin, the corresponding curing agent is urotropine. ; When the resin is made of polyurethane resin or acrylic resin, the corresponding curing agent is made of isocyanate.

[0039] The proppant body in the embodiment can also be a proppant body made of aggregate and a film layer wrapped outside the aggregate, and the film layer is prepared from resin, curing agent, catalyst and amine compound; The resin is a polyol resin (one or m...

Embodiment 1

[0041] This embodiment discloses a method for preparing a film-coated proppant for fracturing, which includes the following steps:

[0042] (1) Prepare the following raw materials: 740 parts of water, 70 parts of acrylamide, 80 parts of 2-acrylamido-2-methylpropanesulfonic acid, 30 parts of polyenylamine, and 80 parts of dimethyl diallyl ammonium chloride and 5 parts of initiator; among them, ammonium persulfate is selected as the initiator, and vinylamine is selected as the polyenamine. In this embodiment, the proppant body is made of the following raw materials in parts by mass: 100 parts of aggregate, 5 parts of resin and 2 parts of curing agent; wherein the aggregate is 30 / 50 quartz sand, the resin is phenolic resin, and the curing agent Use urotropine.

[0043] (2) Add water in the reactor and heat up to 70°C;

[0044] (3) Stir the materials in the reactor, add acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, vinylamine, dimethyl diallyl ammonium chloride to the r...

Embodiment 5

[0055] The difference between Example 5 and Example 1 is that in this example, the proppant body includes aggregate and a film layer wrapped outside the aggregate, and the film layer is prepared from resin, curing agent, catalyst and amine compound . The aggregate is 30 / 50 quartz sand, the resin is glycerol polymer, the curing agent is toluene diisocyanate, the catalyst is tributyltin, and the amine compound is diethylenetriamine. Among them, 100 parts of aggregate, 3 parts of resin, 2 parts of curing agent, 0.02 parts of catalyst, and 0.3 parts of amine compound;

[0056] The preparation process of the corresponding proppant body in step (6) is: heating the aggregate to 105°C, adding resin and catalyst, mixing and stirring; when the temperature drops to 95°C, adding amine compounds, stirring and mixing; when the temperature drops to 75°C, add the curing agent, mix and stir; the temperature drops to 50°C, take out the pot, and get the proppant body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com