Graphene conductive printing ink and method for preparing same

A technology of conductive ink and graphene, which is applied in ink, household utensils, applications, etc., can solve the problems that the conductivity of carbon black, graphite and carbon fiber cannot meet the development needs, and achieve good printing adaptability, excellent conductivity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

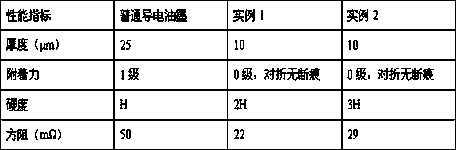

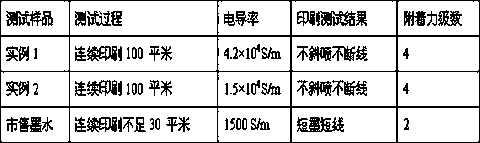

example 1

[0023] Example 1. Weigh 40 parts of phenolic resin, 20 parts of graphene, 25 parts of glycerin, 20 parts of xylene, 2 parts of polyacrylic acid uranium salt, 2 parts of fatty acid ester sulfate, 2 parts of polysiloxane defoamer , 2 parts of polydimethylsiloxane, 2 parts of polyurethane rheology agent, put them into a dispersion tank and stir, mix evenly to obtain a pre-dispersed material; transfer the obtained pre-dispersed material to a grinder until the material fineness Reach below 10 microns; filter the ground material to get graphene conductive ink.

example 2

[0024] Example 2. Weigh 30 parts of bisphenol A epoxy resin, 10 parts of ethylene glycol, 20 parts of xylene, 5 parts of triethylamine, 1 part of polycarboxylate sodium salt, 1 part of fatty acid ester sulfate, polysiloxane 1 part of antifoaming agent, 1 part of polydimethylsiloxane, 1 part of associative acrylate, 30 parts of reduced graphene oxide, put them into the dispersing tank and stir and mix evenly to obtain the predispersed material; The pre-dispersed material is transferred to a grinder and ground until the material fineness reaches below 10 microns; the ground material is filtered to obtain graphene conductive ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com