A kind of thermal decomposition material and preparation method thereof

A technology of thermal decomposition and functional materials, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of the limited size of flexible cotton felt, limited effect, difficult to coat in local areas, etc., and achieve low thermal conductivity and excellent heat absorption performance. , reduce the effect of convective heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

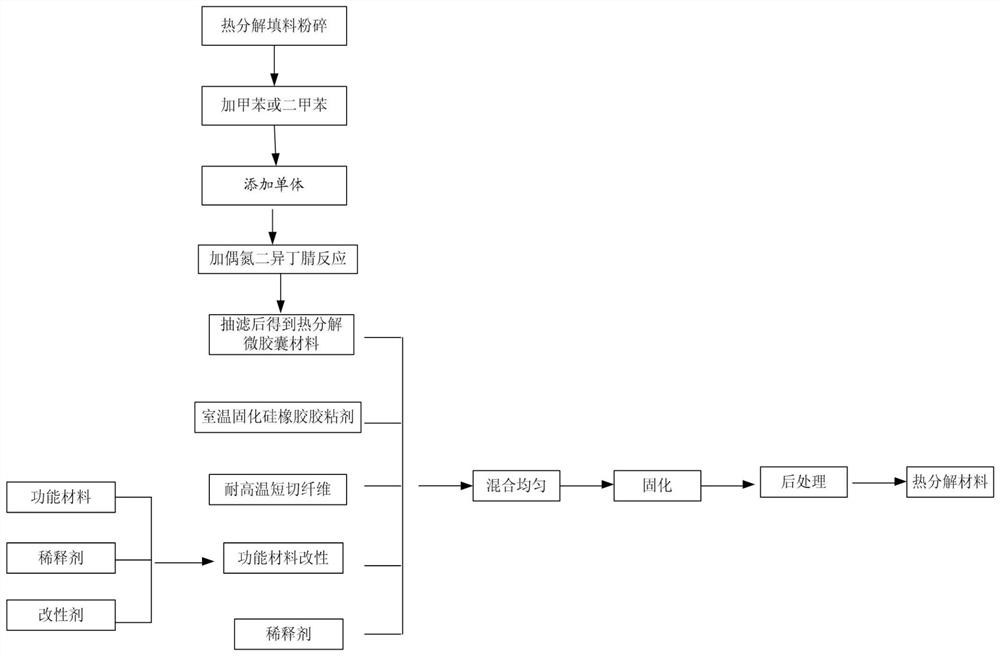

[0063] see figure 1 , the preparation method of the thermal decomposition material provided in this embodiment is as follows:

[0064] The first step is to prepare thermally decomposed filler microcapsules;

[0065] A1.1, mechanically pulverize magnesium hydroxide to 50 μm;

[0066] A1.2, add the crushed magnesium hydroxide into xylene, and mechanically stir to obtain a xylene system; the mass percentage of magnesium hydroxide in xylene is 25%.

[0067] A1.3, add a certain amount of maleic anhydride to the xylene system and mechanically stir until it is completely dissolved, and pass nitrogen to remove oxygen; add a certain amount of styrene after complete dissolution, and continue to pass nitrogen, stir while mechanically stirring The rotational speed is 100-500rpm.

[0068] The mass percent content of maleic anhydride in magnesium hydroxide is 15%, and the mass percent content of styrene in magnesium hydroxide is 10%.

[0069] A1.4, add a certain amount of azobisisobutyr...

Embodiment 2~15

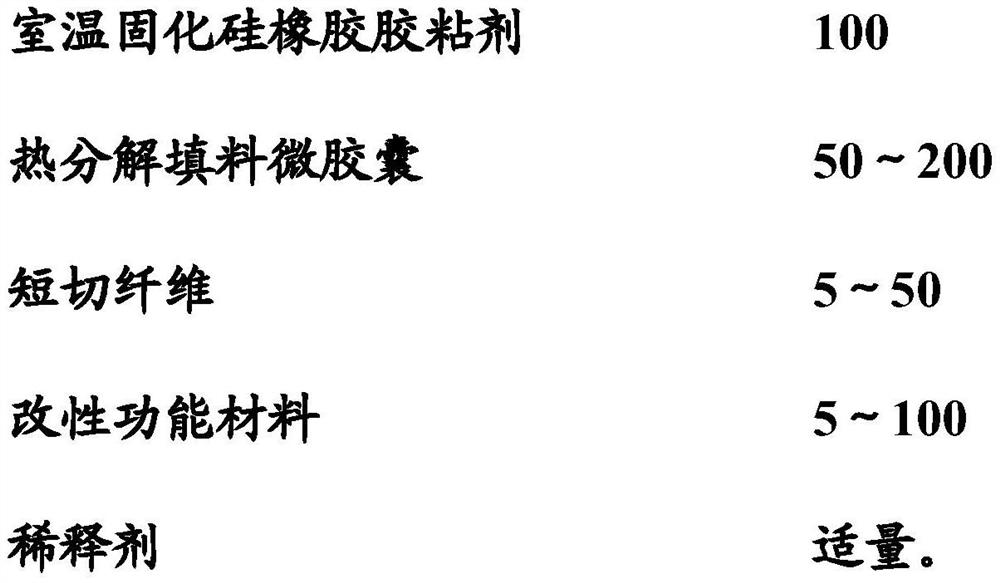

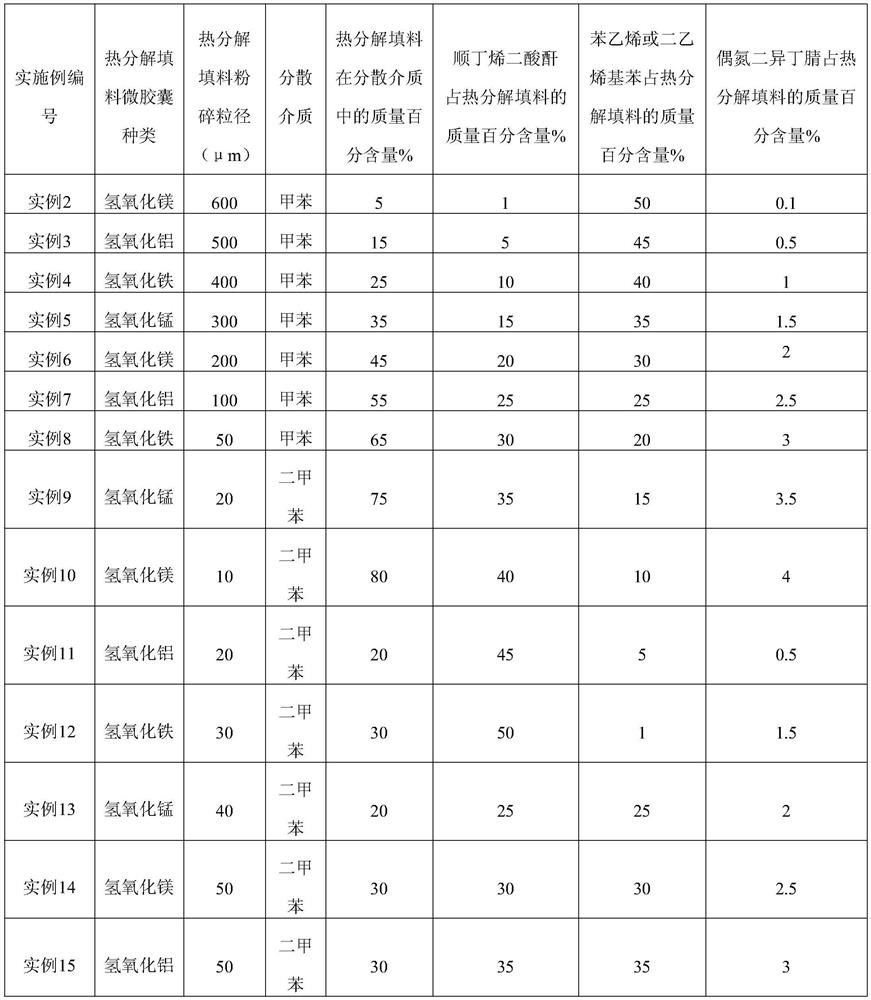

[0079] See Table 1 for the raw materials used in the preparation of thermally decomposed material microcapsules and their preparation ratios in Examples 2-15; see Table 2 for the preparation of thermally decomposed materials and their performance tests in Examples 2-15, and the other contents are the same as in Example 1, wherein:

[0080] The pyrolysis material prepared by the ratio of Examples 2-15: the length and width of the sample are 200mm, the thickness is 15mm, and the apparent density is ≤0.66g / cm 3 , Pyrolysis enthalpy: ≥900J / g; room temperature thermal conductivity: ≤0.085W / m.K.

[0081] Table 1

[0082]

[0083] Table 2

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com