Method for tackifying recycled polyester bottle flake by using chain extender and application thereof

A technology for polyester bottle flakes and polyester recycling, which is applied in the field of comprehensive utilization of polymer materials, can solve the problems of increased molecular weight of r-PET, high equipment requirements, and high investment costs, and achieves enhanced methods, reduced crystallization enthalpy, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

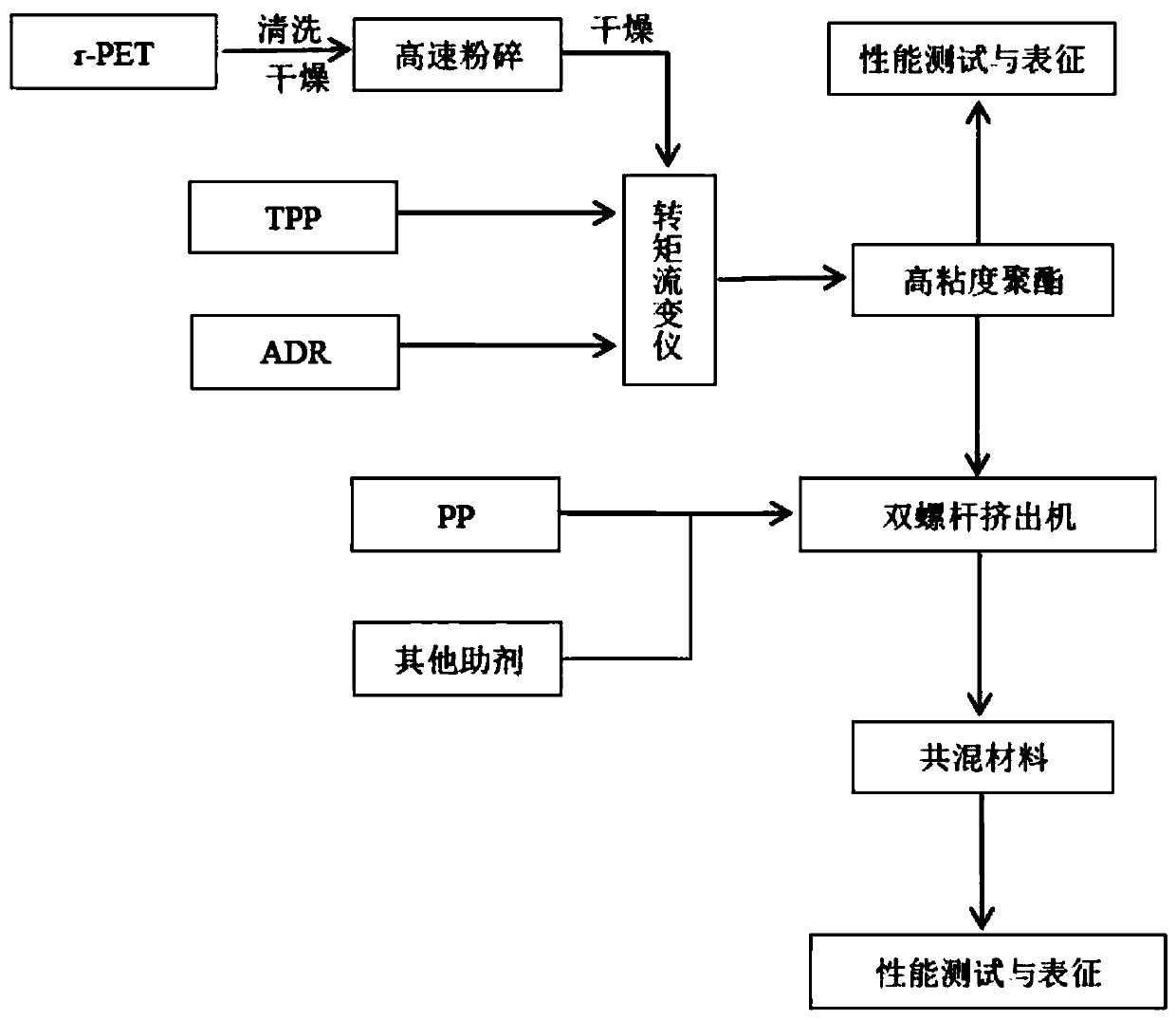

Method used

Image

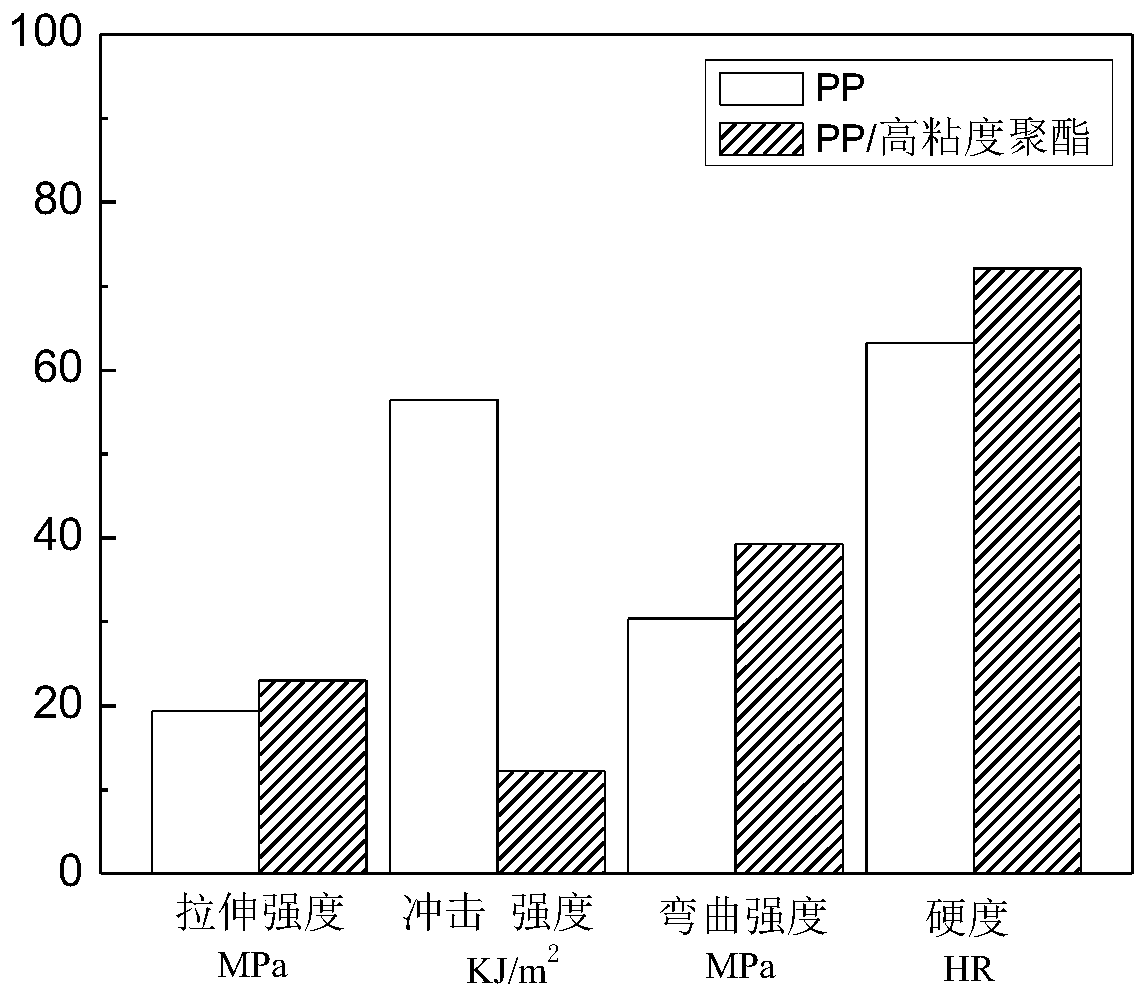

Examples

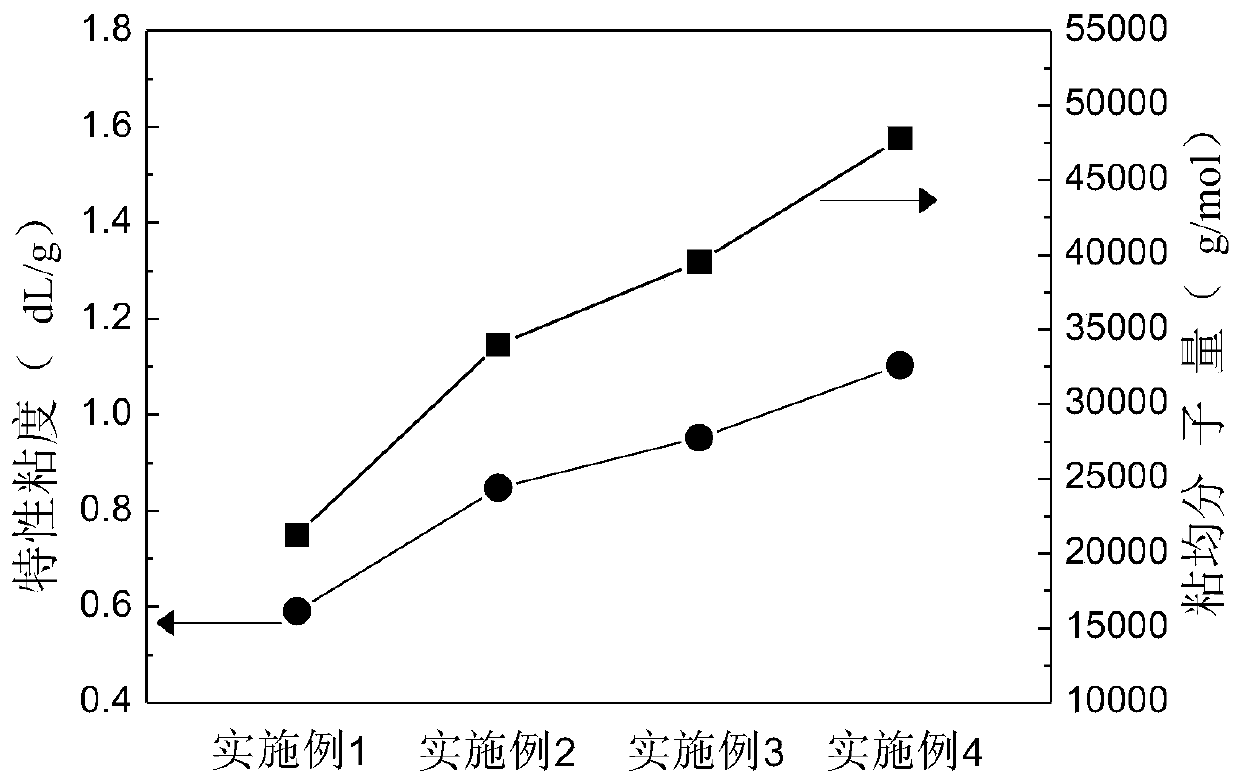

Embodiment 1

[0024] Using r-PET as the base resin, the torque rheometer is used for melt plasticization, and the chain extender TPP / ADR is added in proportion to the molten r-PET for chemical chain extension reaction. The specific preparation process is as follows:

[0025] Step 1: Clean the r-PET and blow dry it at 80°C for 6 hours, then put it into a high-speed multi-functional pulverizer, grind it for 3 minutes, and dry the fine r-PET particles in vacuum at 80°C for 12 hours. Hour;

[0026] Step 2: Add 100 parts of the processed r-PET particles into the torque rheometer, the temperature is controlled at 250°C, the speed is 40r / min, and the r-PET is fully melted after the torque rheometer runs for 4 minutes , adding a total of 1.65 parts of chain extender TPP / ADR (TPP / ADR is 1.5 parts / 0.15 parts), so that r-PET and the chain extender undergo a chemical chain extension reaction, take it out after 10 minutes, and obtain a high-viscosity polyester;

[0027] The third step: take by weighing...

Embodiment 2

[0029] Using r-PET as the base resin, the torque rheometer is used for melt plasticization, and the chain extender TPP / ADR is added in proportion to the molten r-PET for chemical chain extension reaction. The specific preparation process is as follows:

[0030] Step 1: Clean the r-PET and blow dry it at 80°C for 6 hours, then put it into a high-speed multi-functional pulverizer, grind it for 3 minutes, and dry the fine r-PET particles in vacuum at 80°C for 12 hours. Hour;

[0031] Step 2: Add 100 parts of the processed r-PET particles into the torque rheometer, the temperature is controlled at 250°C, the speed is 40r / min, and the r-PET is fully melted after the torque rheometer runs for 4 minutes , adding a total of 1.75 parts of chain extender TPP / ADR (TPP / ADR is 1.5 parts / 0.25 parts), so that r-PET and the chain extender undergo a chemical chain extension reaction, take it out after 10 minutes, and obtain a high-viscosity polyester;

[0032] The third step: take 0.125g drie...

Embodiment 3

[0034] Using r-PET as the base resin, the torque rheometer is used for melt plasticization, and the chain extender TPP / ADR is added in proportion to the molten r-PET for chemical chain extension reaction. The specific preparation process is as follows:

[0035] Step 1: Clean the r-PET and blow dry it at 80°C for 6 hours, then put it into a high-speed multi-functional pulverizer, grind it for 3 minutes, and dry the fine r-PET particles in vacuum at 80°C for 12 hours. Hour;

[0036] Step 2: Add 100 parts of the processed r-PET particles into the torque rheometer, the temperature is controlled at 250°C, the speed is 40r / min, and the r-PET is fully melted after the torque rheometer runs for 4 minutes , add a total of 2 parts of chain extender TPP / ADR (TPP / ADR is 1.5 / 0.5), make r-PET and chain extender chemical chain extension reaction, take out after 10min, obtain high viscosity polyester;

[0037] The third step: take 0.125g dried high-viscosity polyester with an electronic bala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com