Polymer having surface active function and preparation method and application thereof

A surface-active, polymer technology, used in drilling compositions, chemical instruments and methods, etc., can solve the problems of easy degradation, poor salt resistance, etc., and achieve good viscosity enhancement, good temperature and salt resistance, Improve the effect of hydrophobic association

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

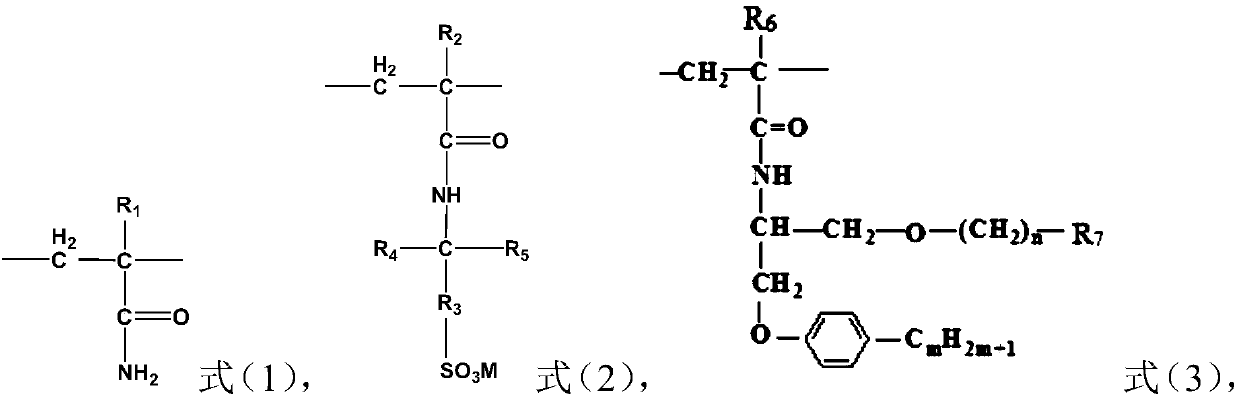

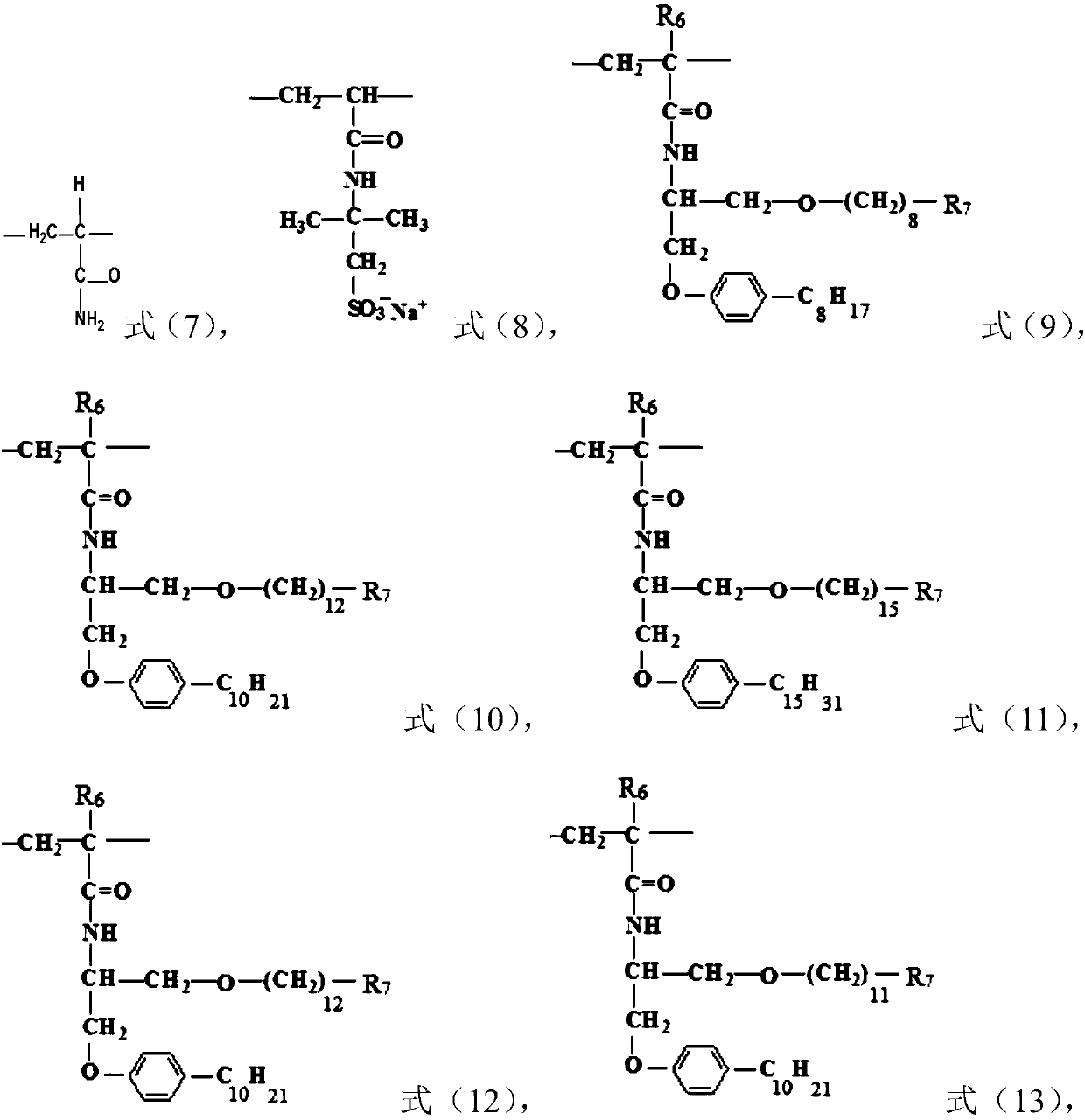

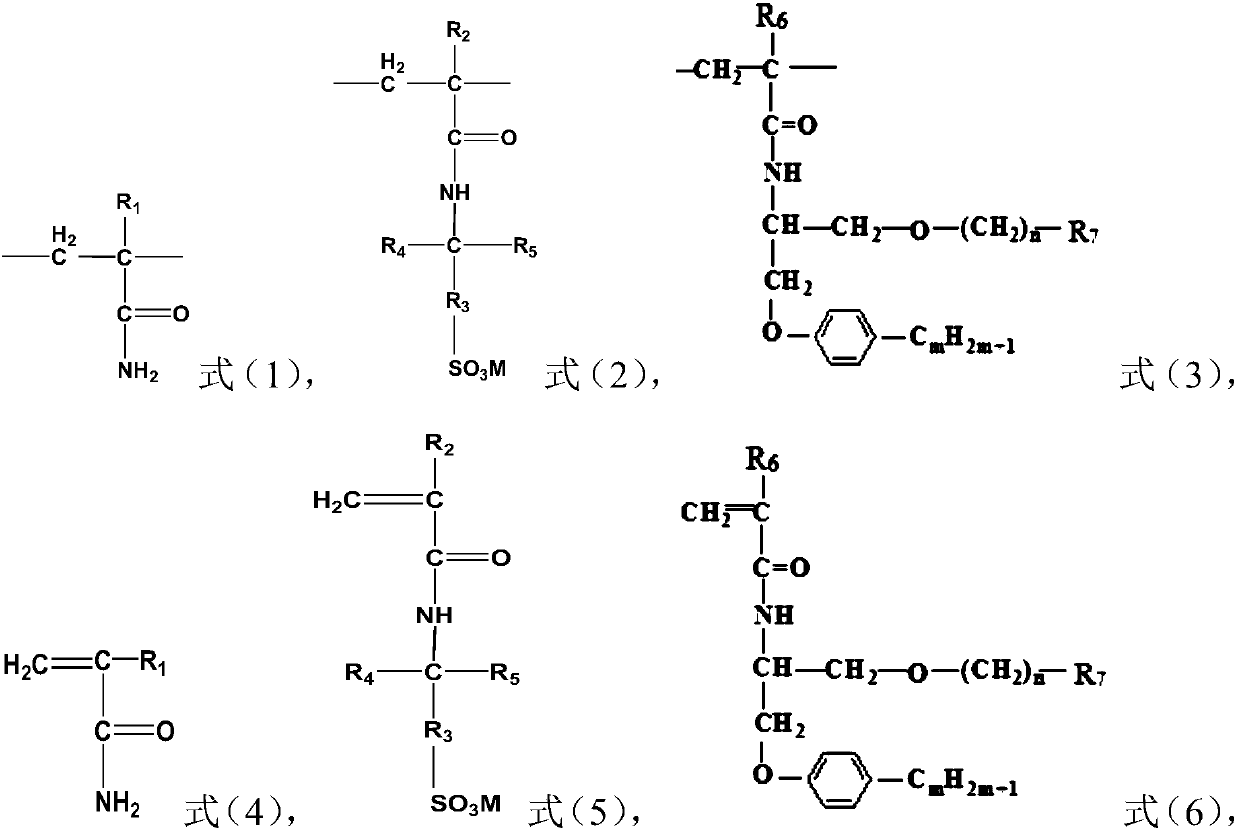

[0035] In the second aspect, the present invention provides a method for preparing a polymer with surface-active function, wherein the method comprises: making monomer D, monomer E and monomer in the presence of an initiator and water as a solvent F is a solution polymerization reaction, wherein the monomer D is a monomer having a structure represented by formula (4), the monomer E is a monomer having a structure represented by formula (5), and the monomer F is A monomer having a structure represented by formula (6), wherein the amount of the monomer D, the monomer E and the monomer F is such that the content of the structural unit A in the prepared polymer is 55-89.9% by weight, and the structural unit The content of B is 10-40% by weight, the content of structural unit C is 0.1-5% by weight, and the viscosity average molecular weight of the prepared polymer is 27 million to 32 million; the structural unit A is of formula (1 ), the structural unit B is a structural unit having...

specific Embodiment approach

[0059] According to a preferred embodiment, the method for preparing the polymer with surface active function includes the following steps:

[0060] Step 1: Add monomer D, monomer E and monomer F to the polymerization reaction flask to prepare an aqueous solution, and adjust the pH of the aqueous solution to 6-10 with alkali;

[0061] Step 2: Add complexing agent, urea aqueous solution and chain extender (tetramethylethylenediamine) to the aqueous solution of step 1, and stir well;

[0062] Step 3: Place the above-mentioned aqueous solution in the water bath of the refrigerator for cooling, and wait until the temperature drops to 10-20°C;

[0063] Step 4: Transfer the above-mentioned cooled aqueous solution to a Dewar flask (polymerization flask), bubbling with nitrogen for 20-40 minutes, and after bubbling with nitrogen to make it uniform, add initiator to the aqueous solution of step 2 , After initiating polymerization, sealing, relying on system polymerization to release heat, auto...

Embodiment 1

[0076] This example is used to illustrate the surface-active polymer provided by the present invention and its preparation method.

[0077] (1) 11.8 g of acrylamide represented by formula (13) (59% by weight of the total monomer), 8.0 g of sodium 2-acrylamido-2-methylpropanesulfonate represented by formula (14) (Accounting for 40% by weight of the total monomer) and 0.2g of the functional monomer represented by formula (15) (R 6 For H, R 7 For SO 3 Na, m is 8, n is 8, accounting for 1% by weight of the total monomer) was added to the preparation bottle, 60.0g of deionized water was added to dissolve the solution to prepare an aqueous solution, and then solid sodium hydroxide was added to adjust the pH to 6.0 to obtain a mixture Solution

[0078] (2) To the above-mentioned mixture solution, add 1% by weight of EDTA-2Na aqueous solution 1.0g (accounting for 0.05% by weight of the total monomer) and 0.5g of 1% by weight urea aqueous solution (accounting for 0.025% by weight of the tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com