Steel wire strip longitudinal tear detection device

A technology of longitudinal tearing and detection device, applied in conveyor control device, transportation and packaging, conveyor and other directions, can solve the problems of longitudinal tearing, high cost, enterprise property loss, etc., to reduce the accident scale and use effect. Ideal, reduce property damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

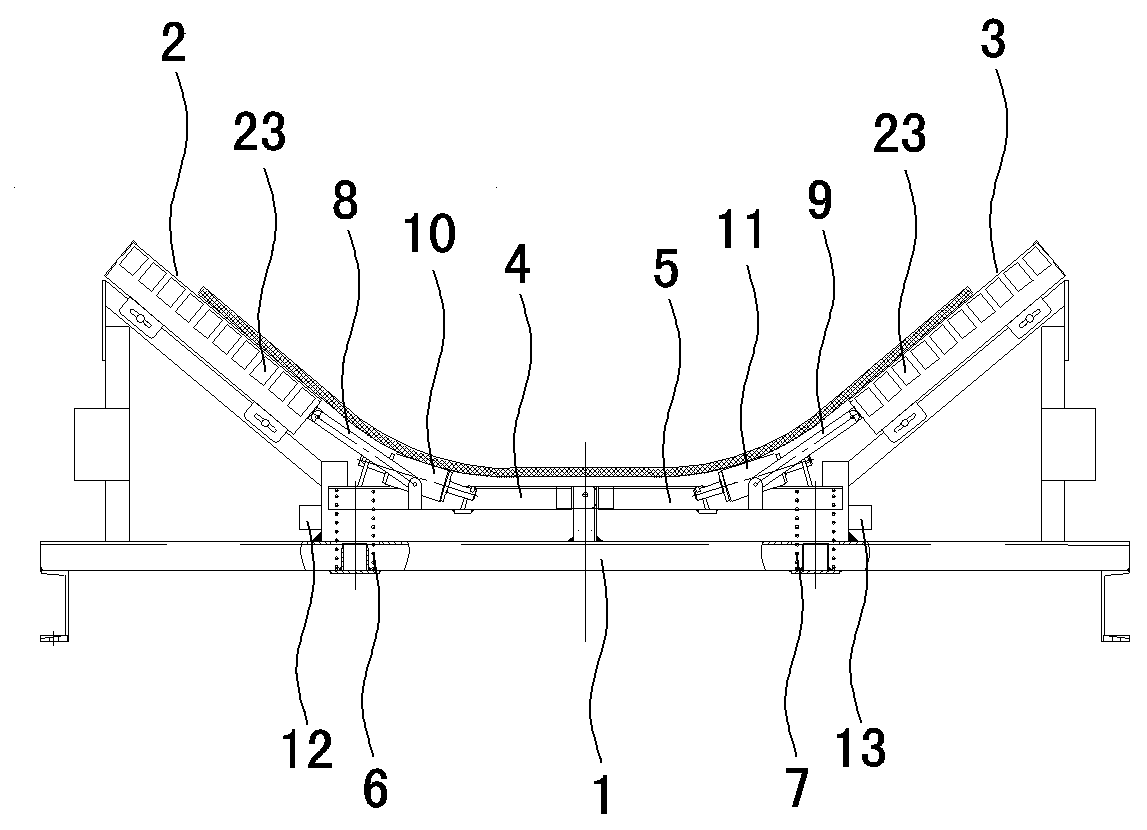

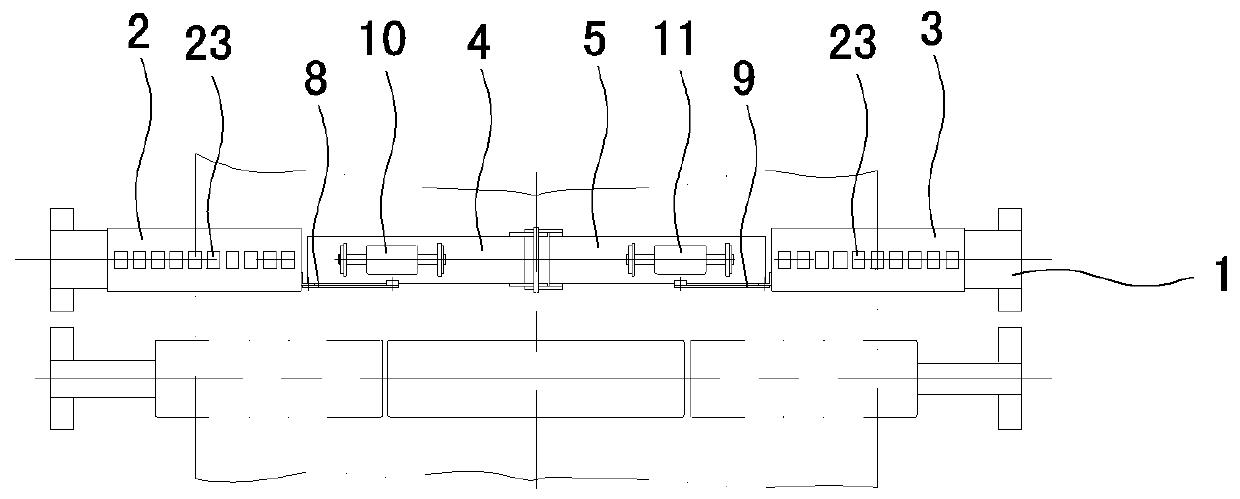

[0008] Such as figure 1 , figure 2 As shown, it comprises a device frame 1, the left and right sides of the device frame 1 are respectively provided with a left detector 2 and a right detector 3 for detecting the positions on both sides of the steel wire belt, and the left detector 2 and the right detector 3 are respectively connected with the two sides of the steel wire belt. The lower surface of the slope surface on the side matches and is installed on the device frame 1 along the axial sliding of the inclined rollers on both sides of the steel wire belt. The device frame 1 is located between the left detector 2 and the right detector 3. The left crossbeam 4 and the right crossbeam 5 below the steel wire belt, one end of the left crossbeam 4 and the right crossbeam 5 is respectively hinged on the middle part of the device frame 1 with the traveling direction of the steel wire tape as the hinge axis, and the other end is respectively towards the left side of the device frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com