Bulletproof blast-protection composite glass of automobile and manufacturing method thereof

A technology of composite glass and bulletproof glass, applied in chemical instruments and methods, glass/slag layered products, protective equipment, etc., can solve problems such as difficult vehicle protection, heavy modification workload, and complicated modification work, and achieve structural applicability Wide range of applications and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

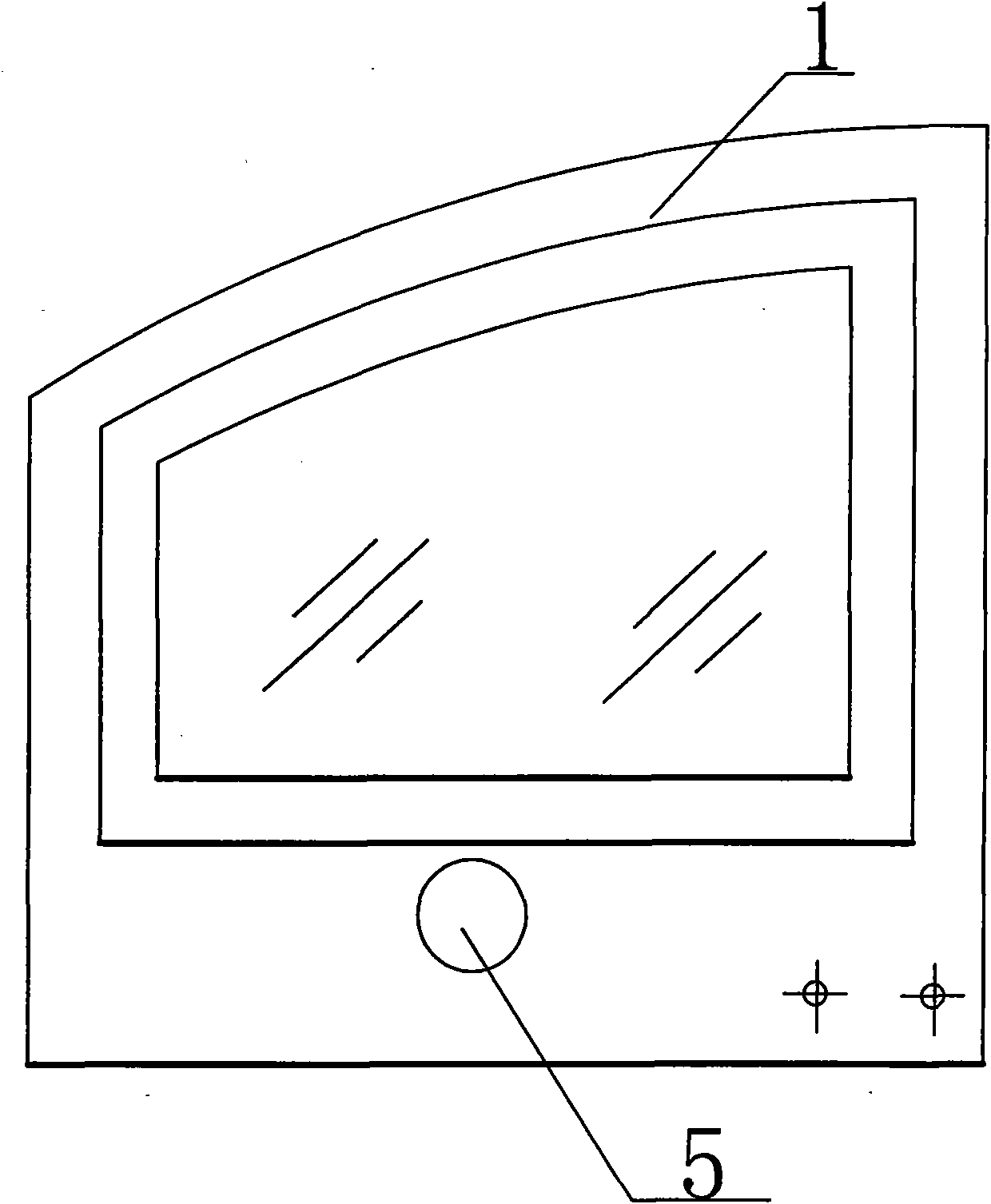

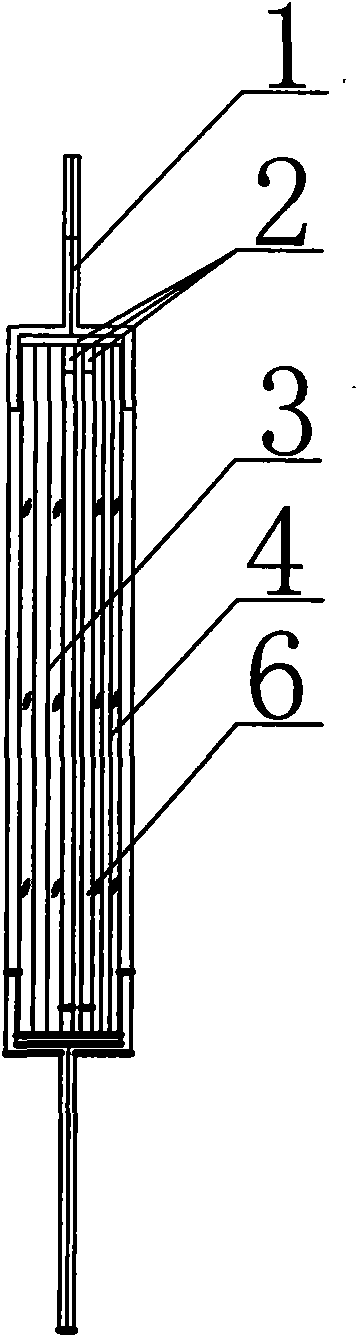

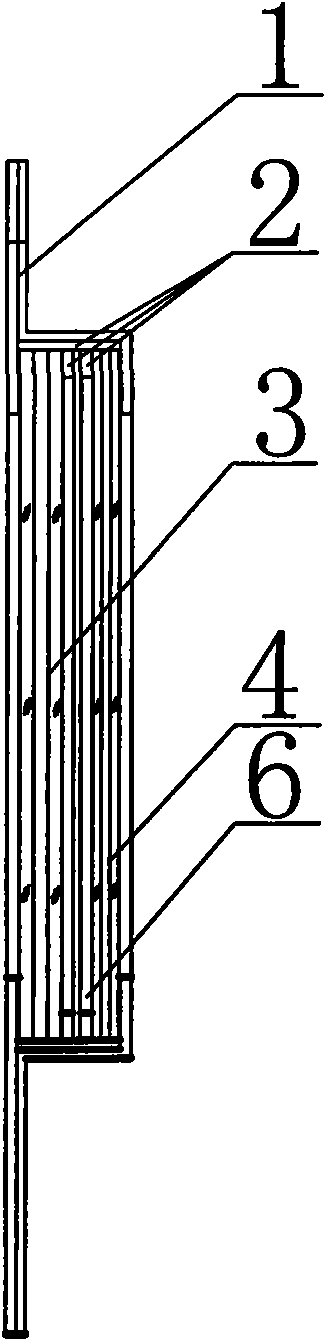

[0020] Depend on figure 2 , image 3 and Figure 4 It can be seen that the automobile bulletproof and explosion-proof composite glass is mainly composed of a bulletproof and explosion-proof steel skirt 1, a buffer glue layer 2, a bullet-proof glass unit 3 and an explosion-proof glass unit 4. A buffer glue layer 2 is provided between the bulletproof and explosion-proof steel skirt 1 , the bulletproof glass unit 3 and the explosion-proof glass unit 4 .

[0021] Depend on figure 2 , image 3 and Figure 4 It can also be seen that the bullet-proof and explosion-proof steel skirt 1 is made of bullet-proof steel plates, and the bullet-proof steel plates are welded by sheet metal to form a "U"-shaped inner opening and a "1"-shaped outer edge, and the "U"-shaped inner opening is equipped with a bullet-proof Explosion-proof glass.

[0022] De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com