Novel blanket base net for press part of paper machine

A paper machine and press section technology, applied in paper machine, paper, textile and paper making, etc., can solve the problems of affecting the dehydration efficiency of felts, low production efficiency, and the inability of looms to mass-produce base webs, etc., and improve the pressing efficiency. , The effect of improving production efficiency and increasing opening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to highlight the purpose, technical solutions and advantages of the present invention, the present invention will be further described in conjunction with the accompanying drawings, but the present invention is not therefore limited to the scope of the embodiments.

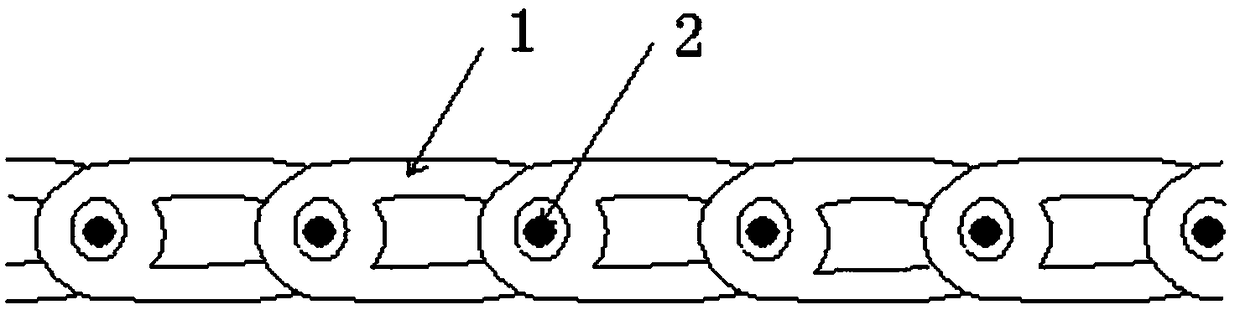

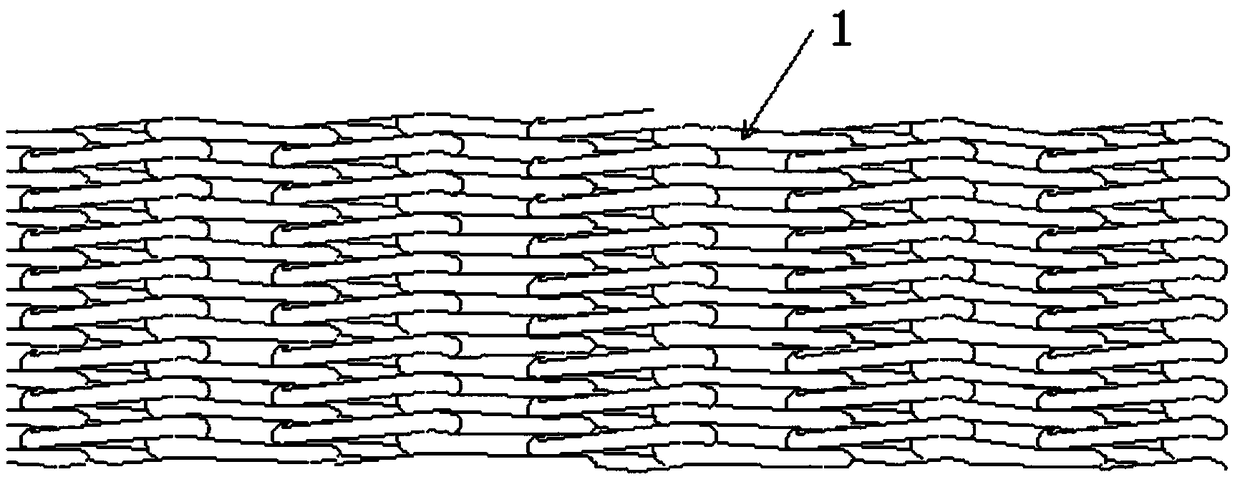

[0017] Depend on figure 1 and figure 2 As shown, the felt base web of the new paper machine press section of the present invention is composed of spiral rings 1 and threading 2, and several spiral rings 1 are arranged side by side to form a spiral ring row group, and several spiral ring row groups are interwoven to form a felt base web. The helical ring row groups are connected by threads 2, and the helical rings 1 of two adjacent helical ring row groups are arranged alternately.

[0018] Specifically, both the spiral loop 1 and the threading thread 2 are polyamide monofilaments, and the diameter of the polyamide monofilaments is preferably 0.3-0.5 mm.

[0019] The above-mentioned spiral network...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com