Diversion net for vacuum perfusion and preparation method and application thereof

A technology of vacuum infusion and diversion net, which is applied in the field of diversion net, can solve the problems of resin residue and other problems, and achieve the effects of high production efficiency, uniform material and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

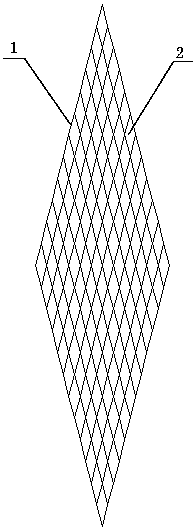

[0023] Such as figure 1 As shown, a deflector net for vacuum perfusion includes a net body 1 . The mesh body 1 has a rhombus structure; the mesh body 1 is provided with a plurality of dense grids 2; the mesh 2 has a rhombus structure; the size of the mesh 2 is 2*2mm; The thickness of the net body 2 is 0.8 mm; the adjacent angles of the grids 2 of the diamond structure are 70 degrees and 110 degrees respectively; the net body 1 is made of polypropylene resin and polyethylene resin materials. Further preferably, in order to increase rapid water diversion, the mesh body 1 is formed by interlacing thick and thin filaments.

[0024] A preparation method for a vacuum perfusion guide net, the steps are as follows:

[0025] S1. Add raw materials to the extruder, heat the extruder to 175°C, and turn on the cooling water at the same time to cool the diversion net of the outlet die, and quickly immerse the net at the outlet end of the die in the water tank, and connect the tractor; Th...

Embodiment 2

[0031] Such as figure 1 As shown, a deflector net for vacuum perfusion includes a net body 1 . The mesh body 1 has a rhombus structure; the mesh body 1 is provided with a plurality of dense grids 2; the mesh 2 has a rhombus structure; the size of the mesh 2 is 2*2mm; The thickness of the mesh body 2 is 0.95mm; the adjacent angles of the mesh 2 of the diamond structure are 70 degrees and 110 degrees respectively; the mesh body 1 is made of polypropylene resin and polyethylene resin materials. Further preferably, in order to increase rapid water diversion, the mesh body 1 is formed by interlacing thick and thin filaments.

[0032] A preparation method for a vacuum perfusion guide net, the steps are as follows:

[0033] S1. Add raw materials to the extruder, heat the extruder to 190°C, and turn on the cooling water at the same time to cool the diversion net of the outlet die, and quickly immerse the net at the outlet end of the die in the water tank and connect the tractor; Th...

Embodiment 3

[0039] Such as figure 1 As shown, a deflector net for vacuum perfusion includes a net body 1 . The mesh body 1 has a rhombus structure; the mesh body 1 is provided with a plurality of dense grids 2; the mesh 2 has a rhombus structure; the size of the mesh 2 is 2*2mm; The thickness of the net body 2 is 1.1 mm; the adjacent angles of the grids 2 of the diamond structure are 70 degrees and 110 degrees respectively; the net body 1 is made of polypropylene resin and polyethylene resin materials. Further preferably, in order to increase rapid water diversion, the mesh body 1 is formed by interlacing thick and thin filaments.

[0040] A preparation method for a vacuum perfusion guide net, the steps are as follows:

[0041] S1. Add raw materials to the extruder, heat the extruder to 210°C, and turn on the cooling water at the same time to cool the diversion net of the outlet die, and quickly immerse the net at the outlet end of the die in the water tank, and connect the tractor; Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com