Perpendicular detecting method for detecting battery diaphragm liquid absorption speed and liquid protection volume

A detection method and a battery separator technology, which are applied in measuring devices, suspension and porous material analysis, permeability/surface area analysis, etc., can solve the problems that the ratio of samples affects the accuracy and timeliness of detection results, and achieve low implementation difficulty , Precise fluid retention and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

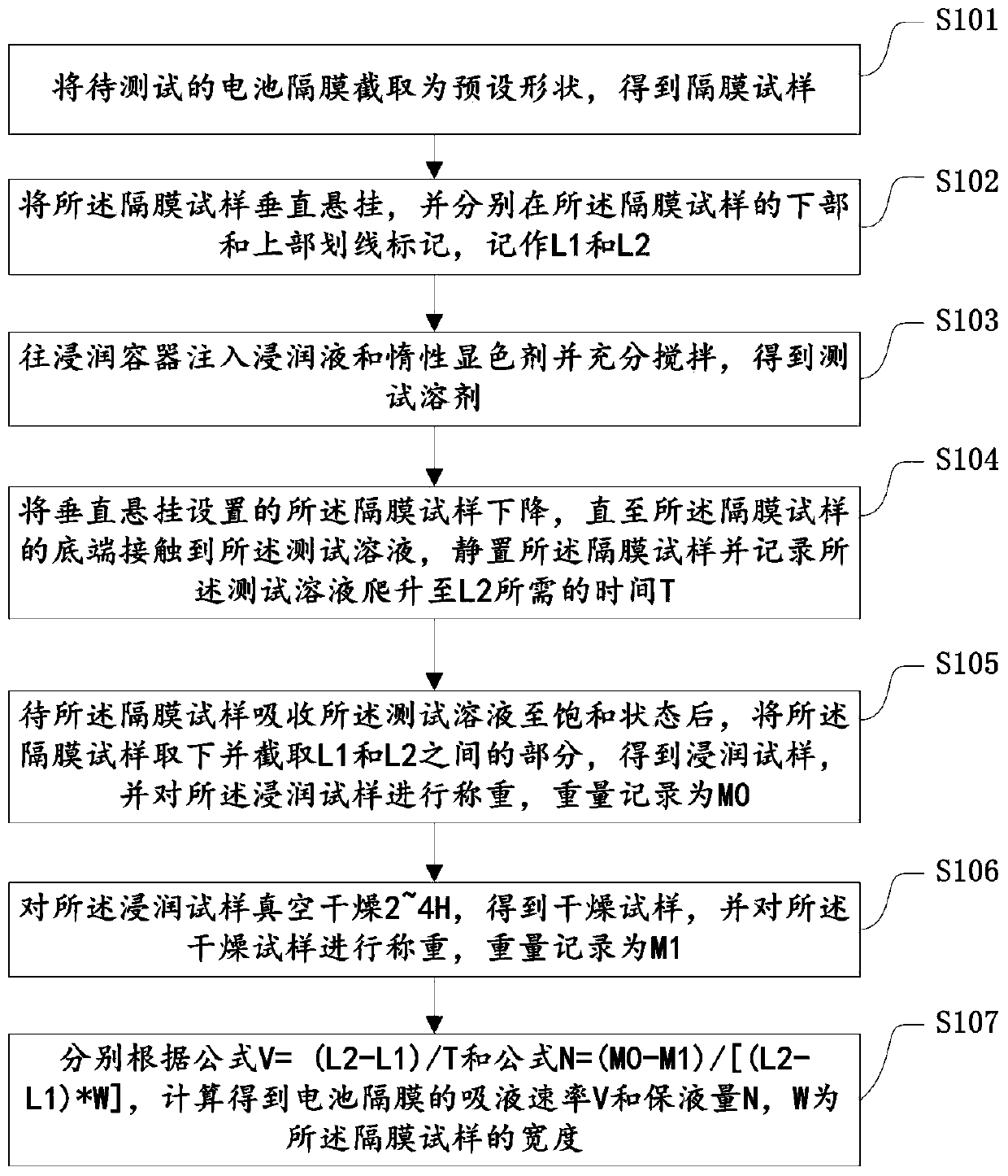

[0042] see figure 1 , the diagram provides a flow chart of a vertical detection method for detecting the liquid absorption rate and liquid retention capacity of the battery diaphragm for this embodiment, and the method includes the following steps:

[0043] S101: Cutting the battery separator to be tested into a preset shape to obtain a separator sample;

[0044] The preset shape is a rectangle or a trapezoid, and the specific area size is determined by the size of the sample, while the diaphragm sample in this embodiment is a rectangle, its length L is 150-300 mm, and its width is 70-150 mm;

[0045] S102: Hang the diaphragm sample vertically, and draw marks on the lower and upper parts of the diaphragm sample respectively, denoted as L1 and L2; specifically, in this embodiment, a 5 ~ 30g glass rod, the diaphragm sample is pulled by the glass rod to keep it vertical to the ground;

[0046] Specifically, hang the diaphragm sample vertically above the infiltrator; the marked ...

Embodiment 2

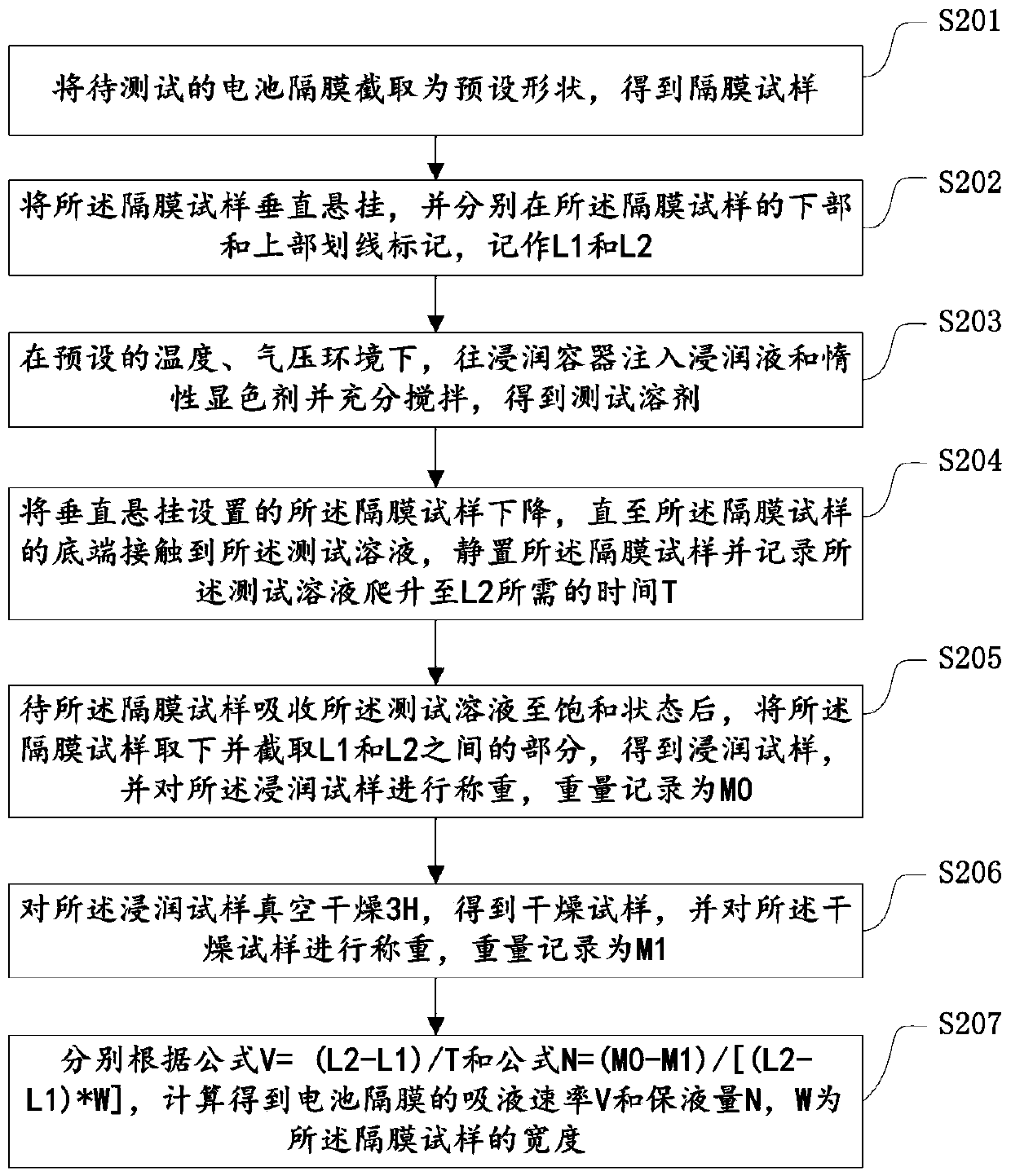

[0059] see figure 2 , the diagram provides one of the specific flowcharts of a vertical detection method for detecting the liquid absorption rate and liquid retention capacity of the battery diaphragm for this embodiment, and the method includes the following steps:

[0060] S201: Cutting the battery separator to be tested into a preset shape to obtain a separator sample;

[0061] The preset shape is a rectangle or a trapezoid, and the specific area size is determined by the size of the sample, while the diaphragm sample of this embodiment is a rectangle, its length L is 100-200 mm, and its width is 50-100 mm;

[0062] S202: hang the diaphragm sample vertically, and mark the lower part and the upper part of the diaphragm sample respectively, denoted as L1 and L2;

[0063] Specifically, hang the diaphragm sample vertically above the infiltrator; the marked marks are all horizontal lines balanced on the ground, L1 represents the distance from the lower marking line of the diap...

Embodiment 3

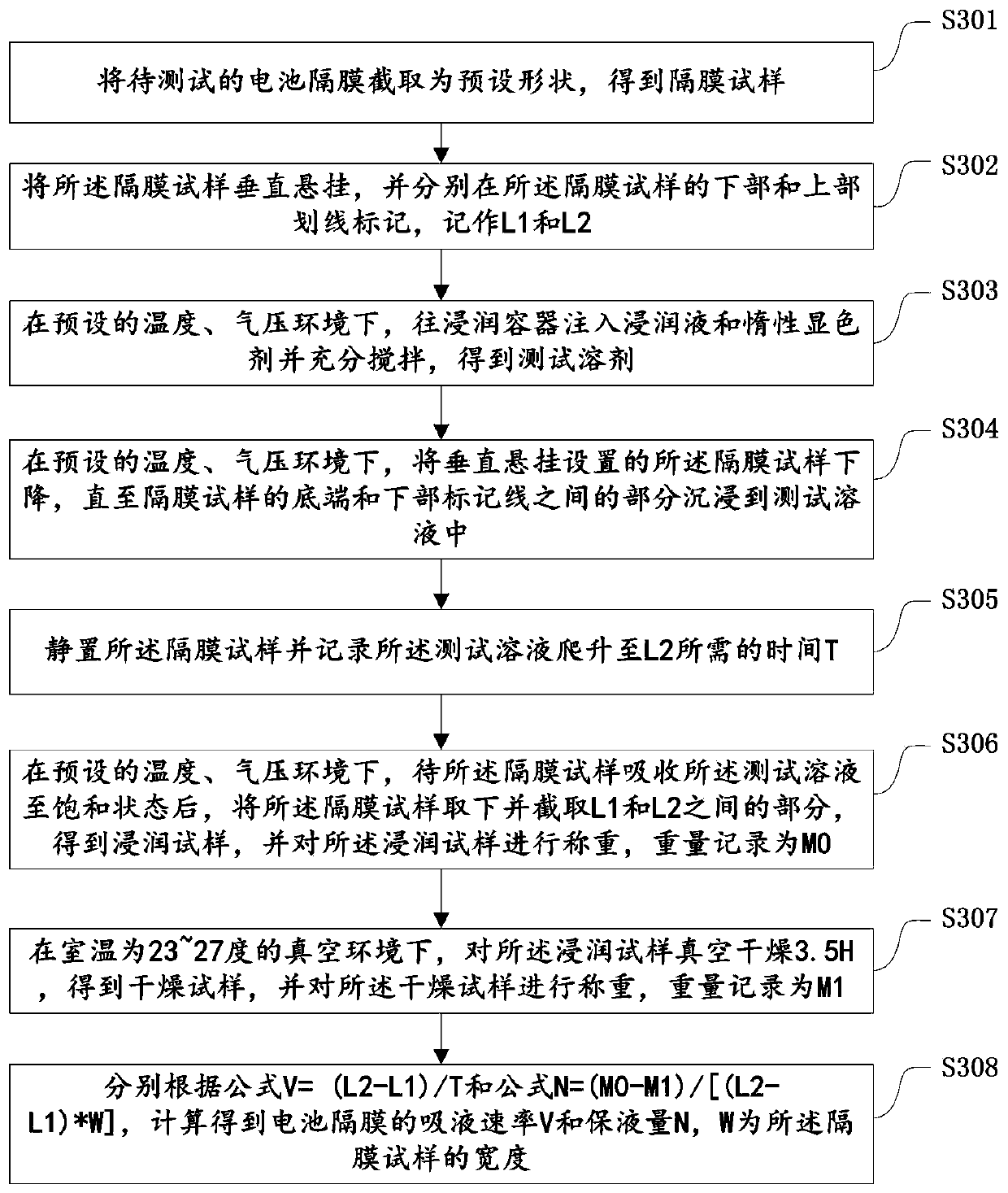

[0075] see image 3 , the diagram provides the second specific flow chart of a vertical detection method for detecting the liquid absorption rate and liquid retention capacity of the battery diaphragm for this embodiment, and the method includes the following steps:

[0076] S301: Cutting the battery separator to be tested into a preset shape to obtain a separator sample;

[0077] The preset shape is a rectangle or a trapezoid, and the specific area size is determined by the size of the sample, while the diaphragm sample of this embodiment is a rectangle, its length L is 100-200mm, and its width is 50-100mm;

[0078] S302: hang the diaphragm sample vertically, and draw marks on the lower and upper parts of the diaphragm sample respectively, denoted as L1 and L2;

[0079] Specifically, hang the diaphragm sample vertically above the infiltrator; the marked marks are all horizontal lines balanced on the ground, L1 represents the distance from the lower marking line of the diaphr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com