Embedded type flexible anti-piercing material and preparation method thereof

A technology of embedded and composite materials, which is applied in the field of embedded flexible stab-proof materials and their preparation, can solve the problems of hidden safety hazards, heavy weight, neglect of the flexibility of stab-proof materials, etc., and achieve good stab-proof performance and improved flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the above-mentioned embedded flexible anti-stab material comprises the following steps:

[0034] S1: Component 1 and Component 2 are obtained through injection molding technology;

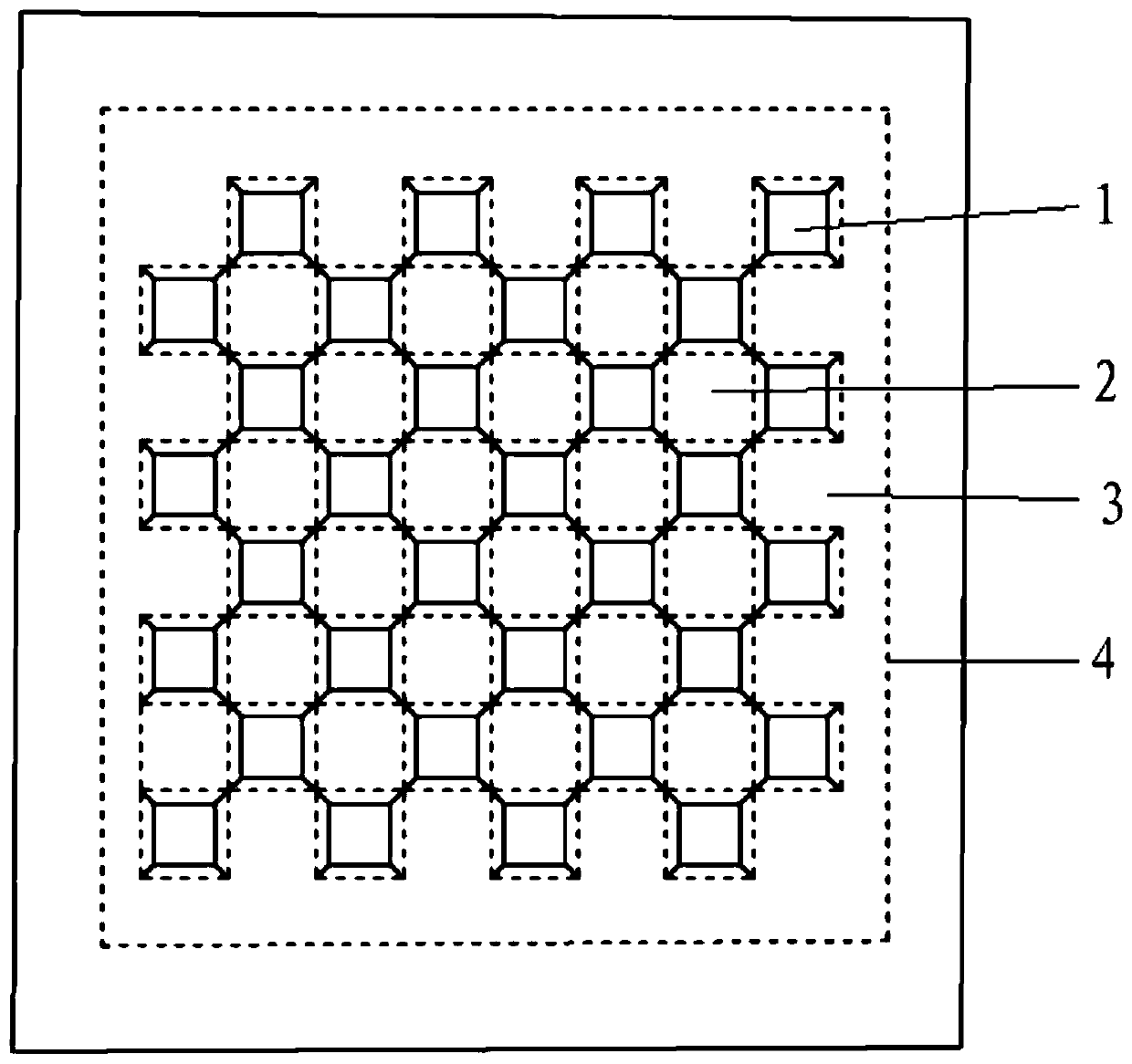

[0035] S2: Bonding component one 1 and component two 2 obtained in step S1 to the upper and lower layers of flexible base fabric 3 respectively according to certain rules and drying, the obtained flexible base fabric 3 is as follows: Figure 4 , 5 shown;

[0036] S3: The components on the two layers of flexible base cloth 3 in the S2 step are mutually fitted (such as Figure 6 shown) and sutured to obtain a flexible stab-resistant material.

Embodiment 1

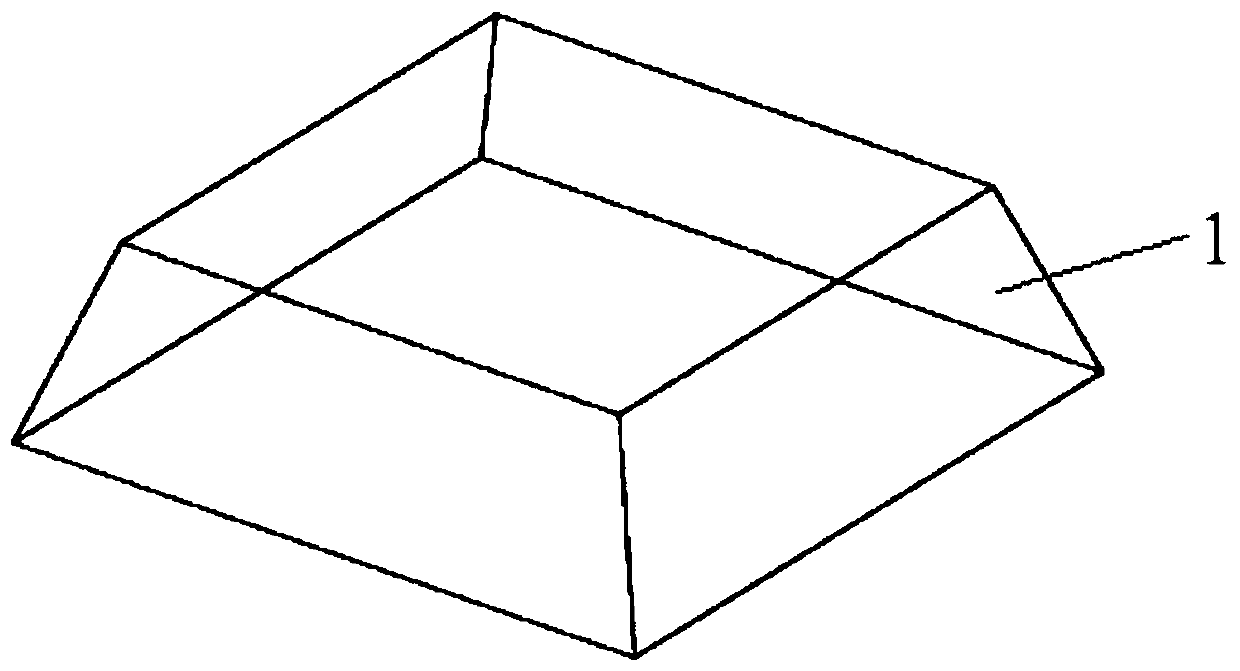

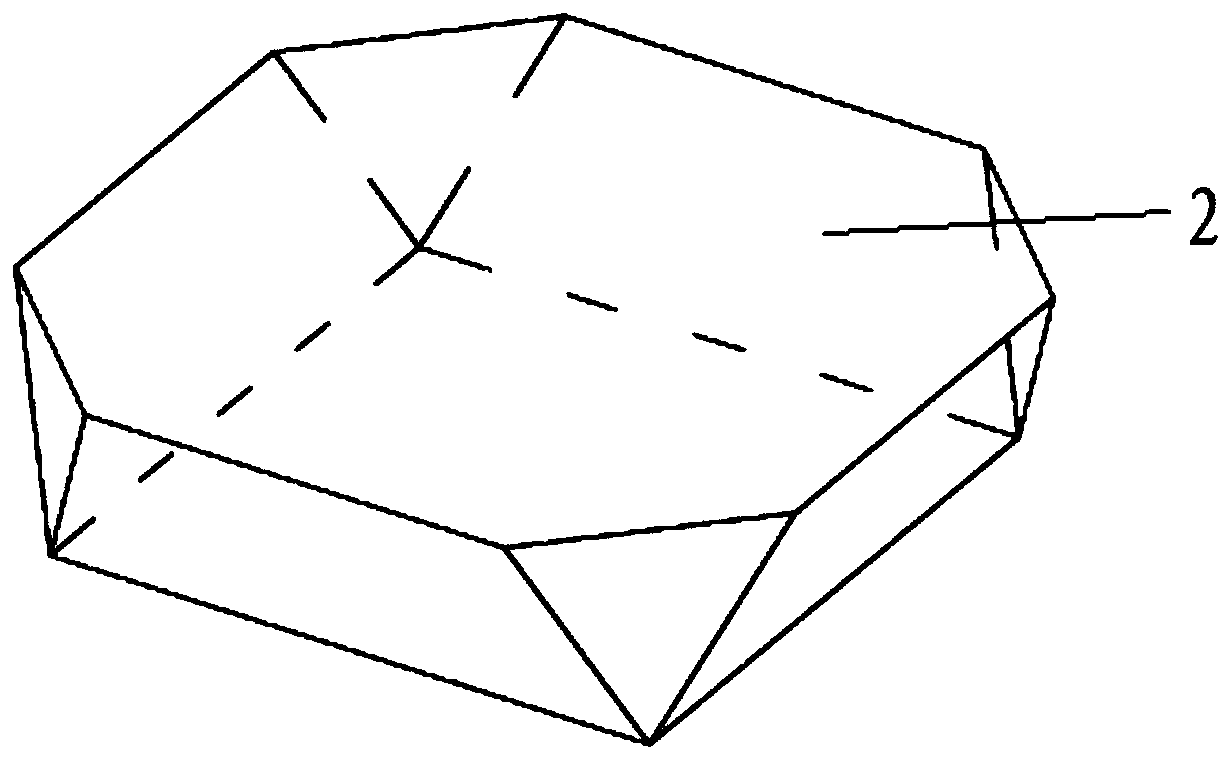

[0038] In the embedded flexible anti-stab material provided in this embodiment, component one 1 and component two 2 are formed by mixing ultra-high molecular weight polyethylene short fibers and thermoplastic polyurethane through injection molding, wherein the high-strength and high-modulus fiber and thermoplastic resin The mass fraction ratio is 1:3. Make component one 1 into a regular quadrangular truss whose lower base length is 20mm, upper base length is 16mm, and height is 2mm. module. The flexible base fabric 3 is aramid plain weave fabric with an area density of 130g / m 2 , the thickness is 0.28mm, the sewing thread 4 is aramid thread, and the fineness is 200D.

[0039] The first component 1 and the second component 2 are prepared by using thermoplastic polyurethane and high-strength and high-modulus short fibers through injection molding technology. And the prepared component one 1 and component two 2 are bonded to the upper and lower layers of aramid base cloth by t...

Embodiment 2

[0041] In the embedded flexible anti-stab material provided in this embodiment, component one 1 and component two 2 are formed by mixing aramid short fiber and thermoplastic polyurethane through injection molding, wherein the mass fraction ratio of high-strength and high-modulus fiber to thermoplastic resin is It is 1:3. Make component one 1 into a regular quadrangular truss whose lower base length is 20mm, upper base length is 16mm, and height is 2mm. module. The flexible base fabric 3 is aramid plain weave fabric with an area density of 130g / m 2 , the thickness is 0.28mm, the sewing thread 4 is aramid thread, and the fineness is 200D.

[0042] The first component 1 and the second component 2 are prepared by using thermoplastic polyurethane and high-strength and high-modulus short fibers through injection molding technology. And the prepared component one 1 and component two 2 are bonded to the upper and lower layers of aramid base cloth by thermoplastic adhesive. Made of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com