An environmentally friendly delayed cross-linking profile control agent for oil recovery, its preparation method and use

A delayed cross-linking and profile control agent technology, which is applied in chemical instruments and methods, production fluids, earthwork drilling and production, etc., can solve the problems that cannot meet the profile control requirements of low-permeability fractured formations, reduce oil recovery, and fail to reach sealing Problems such as plugging cracks, achieving the effect of good industrialization potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

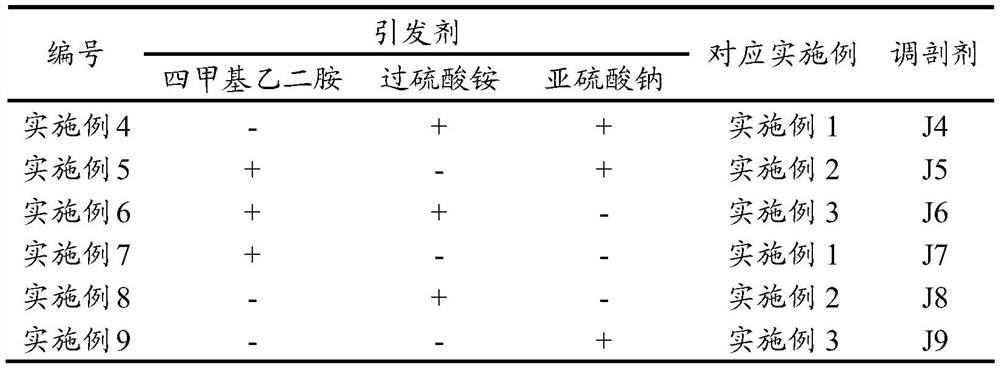

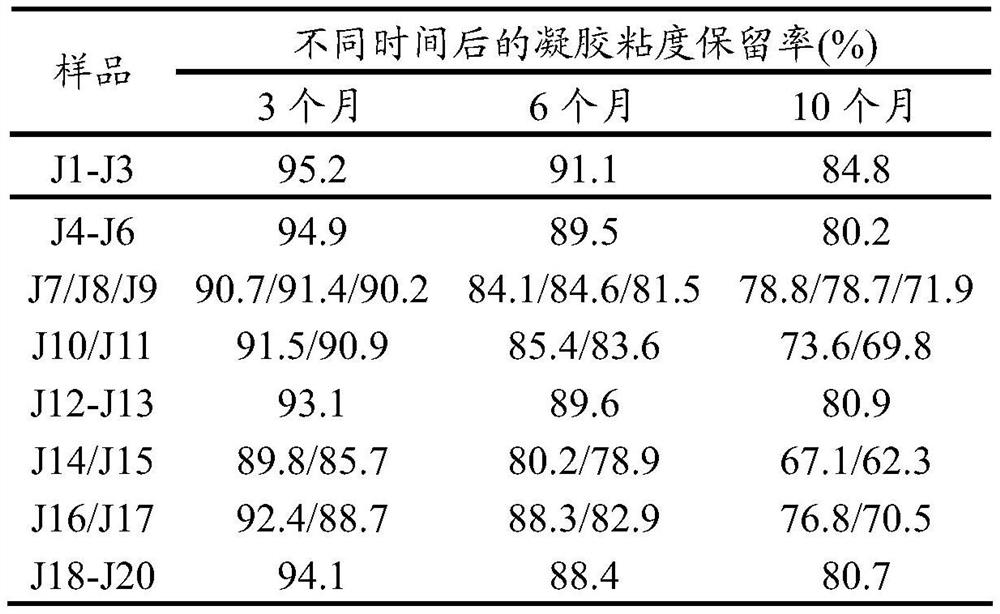

[0053] Example 1: Preparation of delayed cross-linking profile control agent for environment-friendly oil recovery

[0054] S1: Synthesis of salt-resistant polymer solution, specifically:

[0055] In parts by weight, add 18 parts of acrylamide, 5 parts of 2-acrylamido-2-methylpropanesulfonic acid, 0.5 parts of N,N-dimethyl- Hexadecyl allyl ammonium chloride and 0.05 part of sodium formate, stir well, then slowly add the ternary composite initiator (in parts by weight, 0.2 part of tetramethylethylenediamine, 0.1 part of ammonium persulfate and 0.025 a mixture of sodium sulfite), and continue to react at a constant temperature of 10°C for 3 hours to obtain the salt-resistant polymer solution;

[0056] S2: hydrolyzing the salt-resistant polymer solution to obtain a hydrolyzate, specifically:

[0057] At a constant temperature of 40°C, add an appropriate amount of sodium carbonate to the salt-resistant polymer solution, so that the number-average molecular weight of the salt-res...

Embodiment 2

[0062] Example 2: Preparation of delayed cross-linking profile control agent for environment-friendly oil recovery

[0063] S1: Synthesis of salt-resistant polymer solution, specifically:

[0064] In parts by weight, add 20 parts of acrylamide, 3 parts of 2-acrylamido-2-methylpropanesulfonic acid, 1 part of N,N-dimethyl- Hexadecyl allyl ammonium chloride and 0.05 part of sodium formate, stir well, then slowly add the ternary composite initiator (in parts by weight, 0.4 part of tetramethylethylenediamine, 0.05 part of ammonium persulfate and 0.05 part Parts of sodium sulfite mixture), and continue to react at a constant temperature of 12 ° C for 2 hours to obtain the salt-resistant polymer solution;

[0065] S2: hydrolyzing the salt-resistant polymer solution to obtain a hydrolyzate, specifically:

[0066] At a constant temperature of 50°C, add an appropriate amount of sodium carbonate to the salt-resistant polymer solution, so that the number-average molecular weight of the ...

Embodiment 3

[0071] Embodiment 3: Preparation of delayed cross-linking profile control agent for environment-friendly oil recovery

[0072] S1: Synthesis of salt-resistant polymer solution, specifically:

[0073] In parts by weight, add 19 parts of acrylamide, 4 parts of 2-acrylamido-2-methylpropanesulfonic acid, 0.75 parts of N,N-dimethyl- Hexadecyl allyl ammonium chloride and 0.05 part of sodium formate, stir well, then slowly add the ternary composite initiator (in parts by weight, 0.3 part of tetramethylethylenediamine, 0.075 part of ammonium persulfate and 0.038 Parts of sodium sulfite mixture), and continue to react at a constant temperature of 11 ° C for 2.5 hours to obtain the salt-resistant polymer solution;

[0074] S2: hydrolyzing the salt-resistant polymer solution to obtain a hydrolyzate, specifically:

[0075] At a constant temperature of 45°C, add an appropriate amount of sodium carbonate to the salt-resistant polymer solution, so that the number-average molecular weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com