Green body grinding equipment and green body grinding method of ceramic bowl automatic forming production line

A technology for automatic forming and grinding equipment, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc. It can solve the problem of affecting the quality and effect of grinding, the inability to ensure the level of the 8 postures of the round ceramic bowl blank, and the bottom surface of the bowl. Grinding difficulties and other problems, to achieve the effect of maintaining accurate position and posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

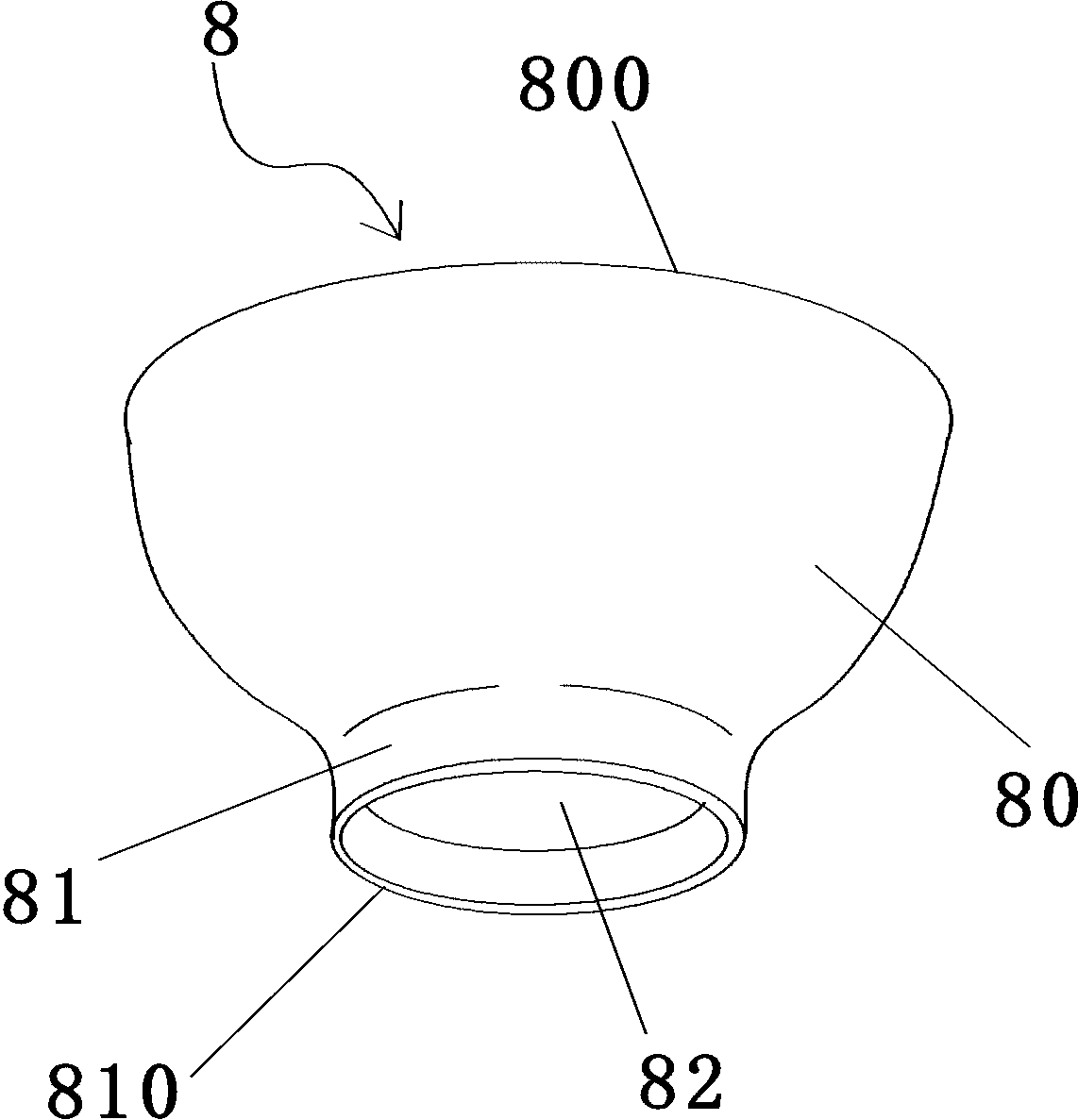

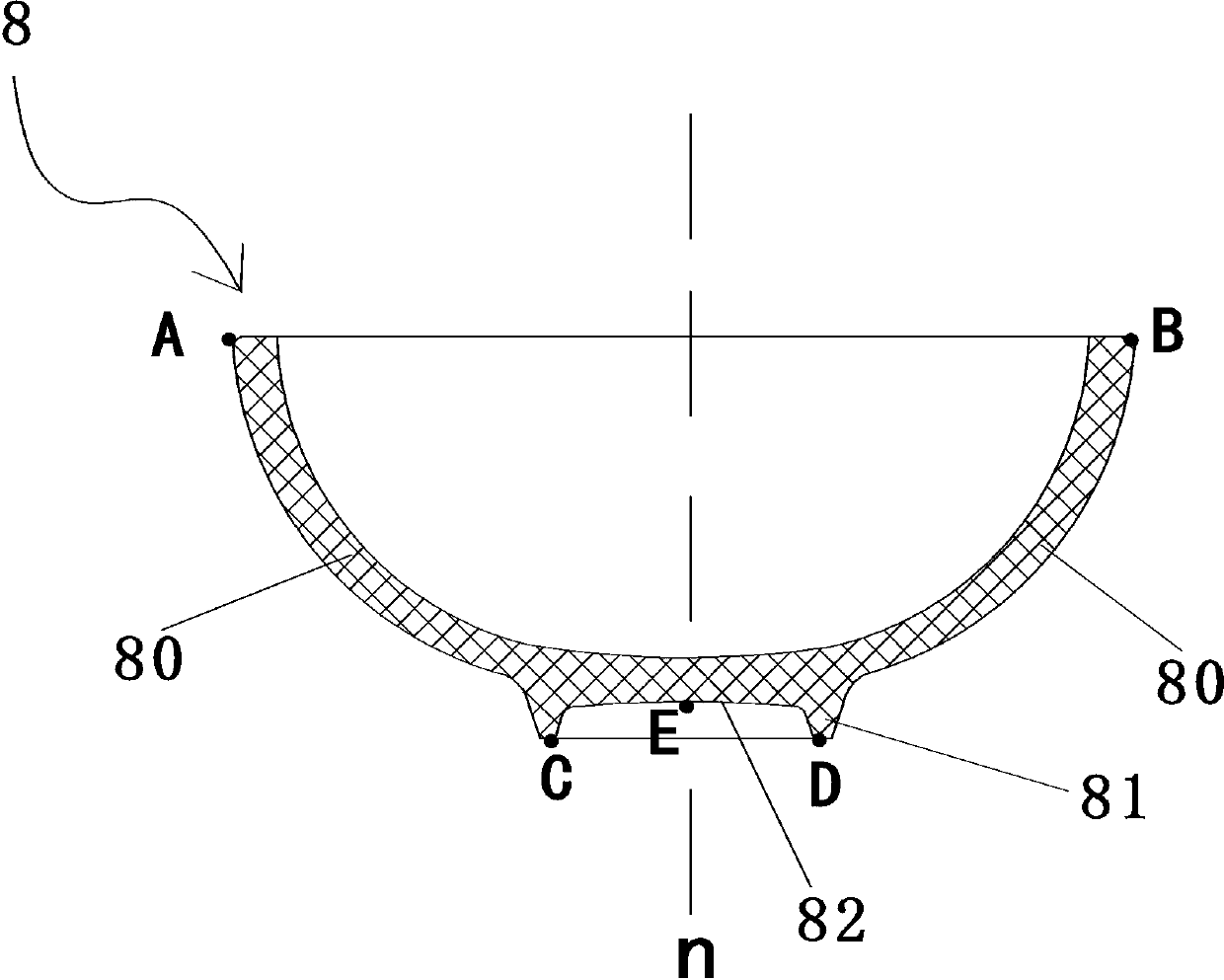

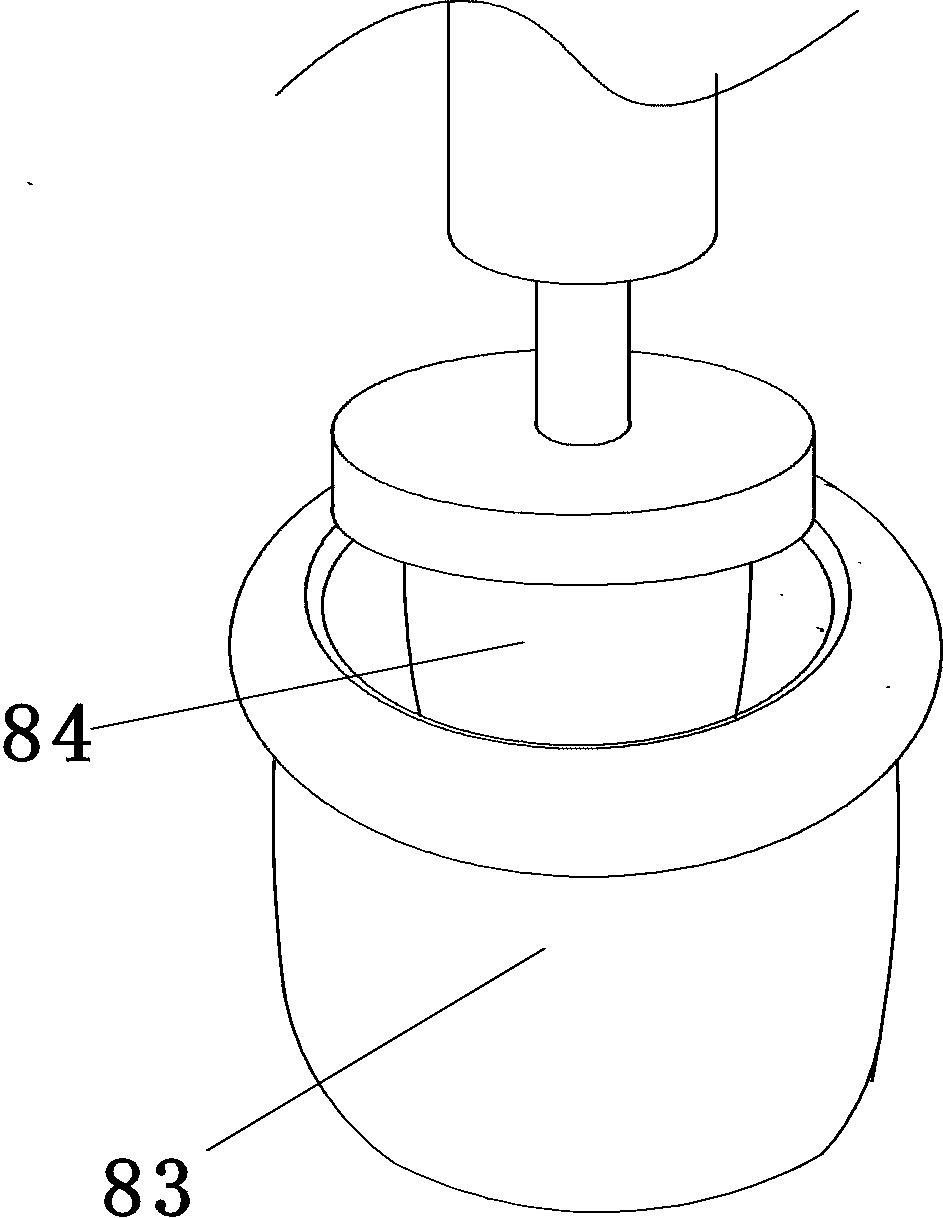

[0060] Figure 7 , Figure 8 , Figure 10 As shown, the green body grinding equipment of the ceramic bowl automatic forming production line includes a circular turntable 5, the rotating shaft of the turntable 5 is vertical, and a turntable drive mechanism is also provided to drive the turntable 5 to rotate around its central axis m; Four vertical support tubes 52 are installed on the turntable 5, and the horizontal distance between the four vertical supports and the central axis of the turntable is equal. The four vertical support tubes 52 are located at the edge of the turntable 5 and are evenly arranged along the circumference of the turntable. The root vertical support tubes 52 can rotate around their respective central axes, and the top of each vertical support tube 52 is equipped with a first suction cup 51, the first suction cup 51 is circular, and the diameter of the first suction cup 51 is equivalent to the The bottom of the bowl base of the bowl blank is along the d...

Embodiment 2

[0068] A green body grinding method of an automatic ceramic bowl forming production line, using the green body grinding equipment of the ceramic bowl automatic forming production line of embodiment 1, comprising the following steps:

[0069] (1) At the beginning, one of the first suction cups 51 of the turntable 5 is located at the blank moving position, and the first electromagnetic valve corresponding to the first suction cup 51 is in a closed state; the second electromagnetic valve of the blank moving mechanism 4 is opened, and the blank moving mechanism The second suction cup 42 sucks the bowl bottom surface of the bowl blank 8 that is ready to accept grinding, and the bowl blank is in an inverted posture, such as Figure 11 As shown, following the action of the manipulator of the blank-moving mechanism, the second suction cup 42 and the bowl blank 8 ready to be ground come to the top of the first suction cup 51 at the blank-moving position, and then the second solenoid val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com