Apparatus to continuously generate hydrates under action of electrostatic atomization

An electrostatic atomization and generation device technology, applied in chemical/physical processes, pressure vessels used in chemical processes, chemical instruments and methods, etc. Inability to separate and other problems to achieve the effect of strengthening heat and mass transfer, facilitating transportation and operation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

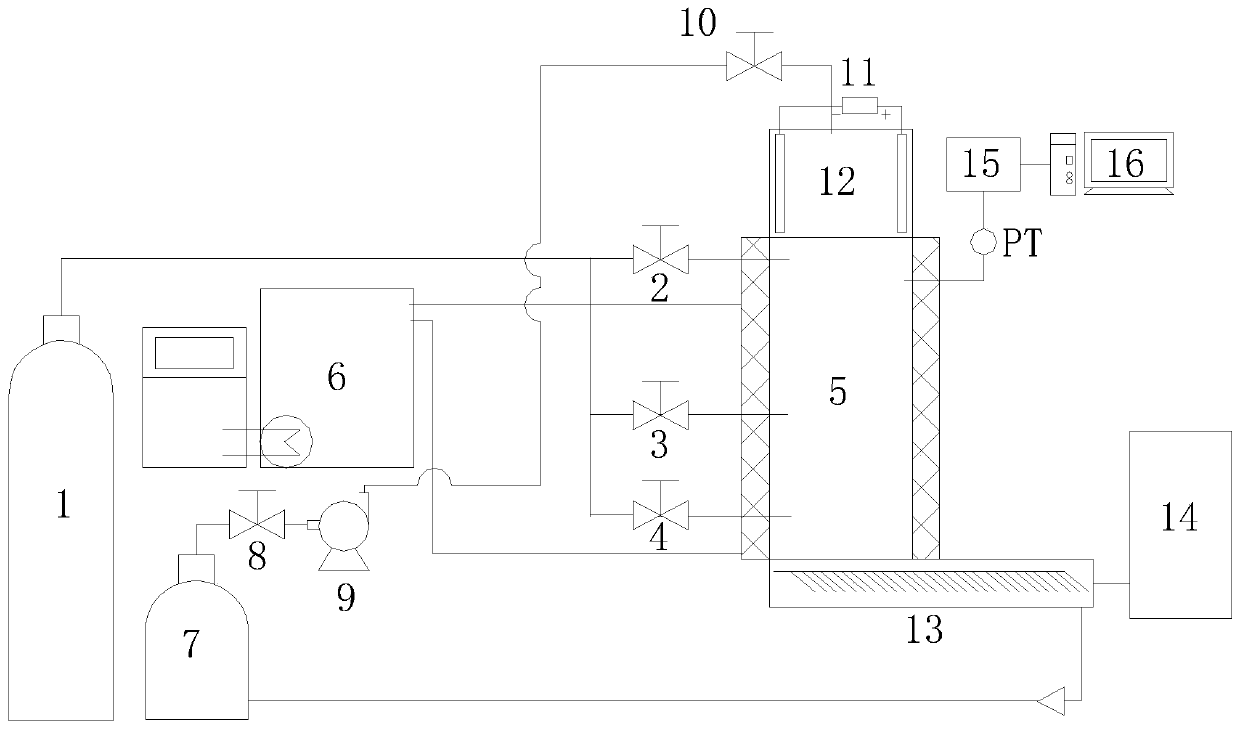

[0017] refer to figure 1 , a device for continuously generating hydrates under the action of electrostatic atomization, including a reactor 5 with a water jacket on the outside, a gas supply unit that provides a gas source and a supergravity environment for the reactor 5, and an ion barrier for the reactor 5. A mist supply unit for the polymerization agent and water mist, a temperature control unit for controlling the temperature of the water jacket, a hydrate filtration and collection unit connected to the reactor 5 and used for filtering and collecting the hydrate crystals generated by it, and a The data acquisition and processing unit that collects and records the temperature and pressure of the reactor 5; the hydrate filtration and collection unit is equipped with multi-layer inclined filter plates with different pores, and realizes the efficient separation of solid and liquid by bouncing and particle size. The lower end of the unit passes through the pipeline Connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com