SA-magnetic bead freeze-drying working solution, SA-magnetic bead freeze-dried product and preparation method of freeze-dried product

A working solution and freeze-drying technology, which is applied to material inspection products, measuring devices, instruments, etc., can solve the problems of unstable luminescence intensity of SA-magnetic beads freeze-dried products, short storage time of SA-magnetic beads, and inconvenient transportation. Achieve the effect of being beneficial to freeze-drying, stable luminescence value, and small effect on activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 freeze-dried working solution

[0034] Prepare the following lyophilized working solutions respectively:

[0035] Freeze-dried working solution A:

[0036] TBS buffer (10 mM Tris-HCl, 0.9% NaCl, pH: 7.4), 1% glycine, 1% inulin, 1% mannitol, 1% sodium caseinate, 0.05% Tween-20, 0.02% ProClin 300.

[0037] Freeze-dried working solution B:

[0038] TBS buffer (20 mM Tris-HCl, 0.9% NaCl, pH: 7.4), 1% glycine, 1% inulin, 2% mannitol, 2% sodium caseinate, 0.05% Tween-20, 0.02% ProClin 300.

[0039] Freeze-dried working solution C:

[0040] TBS buffer (30 mM Tris-HCl, 0.9% NaCl, pH: 7.4), 1% glycine, 2% inulin, 1% mannitol, 3% sodium caseinate, 0.05% Tween-20, 0.02% ProClin 300.

[0041] Freeze-dried working solution D:

[0042] TBS buffer (20 mM Tris-HCl, 0.9% NaCl, pH: 7.4), 1% glycine, 3% inulin, 2% mannitol, 1% sodium caseinate, 0.05% Tween-20, 0.02% ProClin 300.

[0043] Freeze-dried working solution E:

[0044] TBS buffer (40 mM Tri...

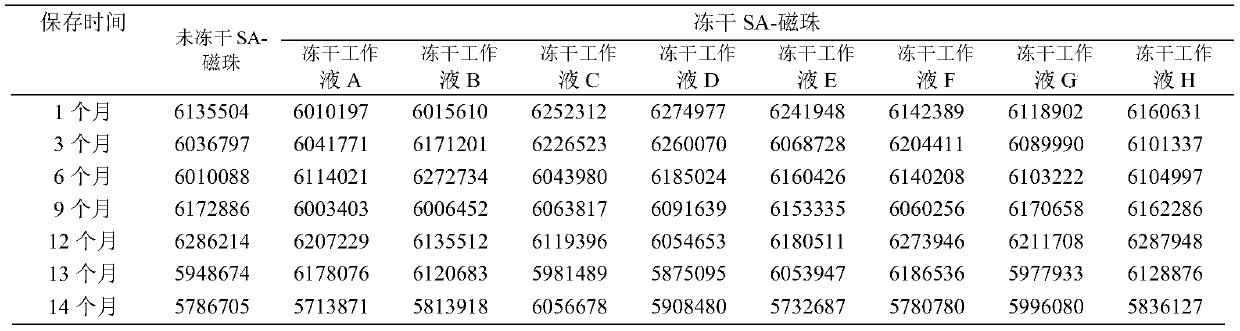

Embodiment 2

[0055] Example 2 Preparation of SA-magnetic beads freeze-dried product

[0056] 1) Adsorb SA-magnetic beads through a magnetic stand, mix SA-magnetic beads with freeze-dried working solutions A, B, C, D, E, F, G, H, I, J, and adjust the content of magnetic beads to 1 % (1 g / 100 mL).

[0057] 2) Spot SA-magnetic beads onto a 0.5cm×0.5cm glass chip with an automatic spotting instrument, 100nL per spot, 7×7 square array, 49 spots in total.

[0058] 3) Freeze-drying of SA-magnetic bead lyophilized product

[0059] Pre-freezing: the chip is put into the box at 4°C, and kept for 1 hour after entering the box, so that all samples are cooled from the same starting point of 4°C to -46°C, and kept at -46°C for 1 hour, and the samples are heated to the eutectic point The temperature was maintained for 1 hour, and then the sample was cooled again and maintained at -46°C for 2 hours.

[0060] Sublimation: Control the temperature of the plate layer to maintain the temperature of the samp...

Embodiment 3

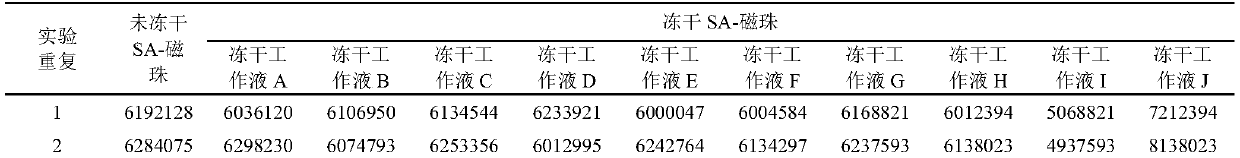

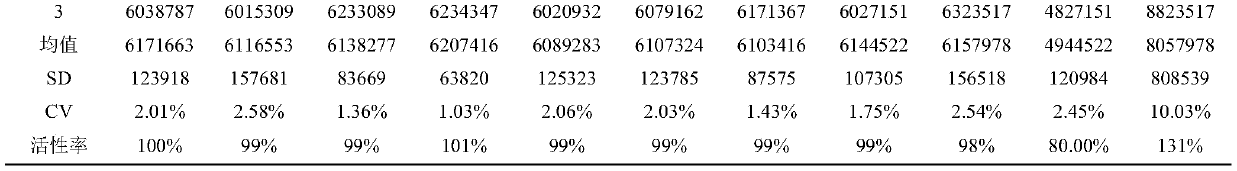

[0064] Example 3 Redissolution and Activity Detection of SA-Magnetic Beads Freeze-dried Product

[0065] 1) Activity detection after freeze-drying and reconstitution of SA-magnetic beads

[0066] Redissolve 10 kinds of SA-magnetic bead lyophilized products with 100 μL ultrapure water;

[0067] Add 2 μL of biotinylated alkaline phosphatase (Biotin-AP) (5 ng / μL) to the 10 kinds of SA-magnetic beads after reconstitution and the same batch of non-lyophilized SA-magnetic bead suspension, and incubate at 37°C for 10 minutes.

[0068] Add 200 μL of SA-magnetic bead washing buffer, absorb and wash three times, and magnetically absorb for 3 minutes each time.

[0069] Add 200 μL enzyme substrate solution, mix well, take 170 μL to a microplate plate, incubate in a microplate reader at 37°C for 5 min, measure the luminescent signal value, and the results are shown in Table 1.

[0070] Table 1 Activity analysis of SA-magnetic beads bound to biotinylated alkaline phosphatase before and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com