Multistage artificial wetland system for treatment of heavy metal wastewater

A constructed wetland system and constructed wetland technology, applied in the field of wastewater treatment, can solve the problems of small amount of treated water, difficult control, secondary pollution, etc., and achieve the effects of increasing microbial biomass, improving processing capacity, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

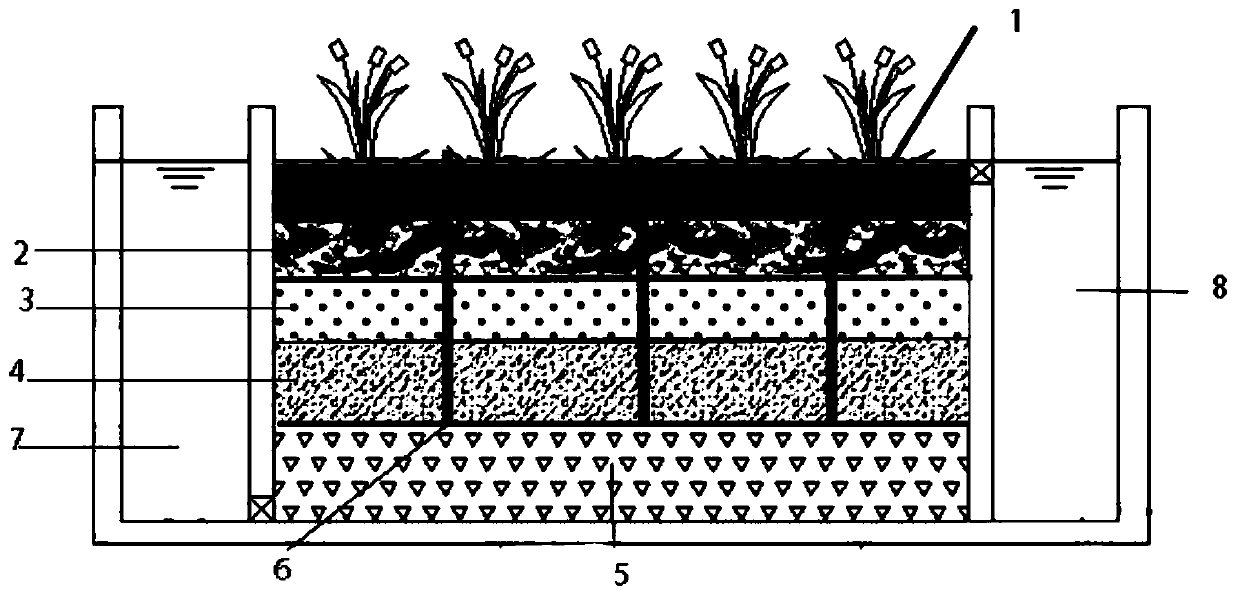

[0023] The multi-level constructed wetland system for treating heavy metal wastewater in this embodiment includes algae ponds, aeration ponds and multi-level constructed wetlands. The multi-level constructed wetlands at least include the first-level constructed wetland and the last-level constructed wetland. The waste water flows through algae ponds and multi-stage constructed wetlands in turn, and the effluent flowing through the last stage of constructed wetlands is recycled to the aeration pool for enhanced oxygen supply, and then flows through the first stage of constructed wetlands until it reaches the standard discharge. The multi-stage constructed wetlands Each level of constructed wetland includes a water inlet area 7, a reaction area and a water outlet area 8. The sewage flows through the reaction area and the water outlet area 8 successively from the water inlet area 7 in the form of porous water distribution; Pore aerator, the microporous aerator is connected to th...

Embodiment 2

[0039] The multi-level constructed wetland system for treating heavy metal wastewater in this embodiment includes algae ponds, aeration ponds and multi-level constructed wetlands. The multi-level constructed wetlands at least include the first-level constructed wetland and the last-level constructed wetland. The waste water flows through algae ponds and multi-stage constructed wetlands in turn, and the effluent flowing through the last stage of constructed wetlands is recycled to the aeration pool for enhanced oxygen supply, and then flows through the first stage of constructed wetlands until it reaches the standard discharge. The multi-stage constructed wetlands Each level of constructed wetland includes the multi-level constructed wetland. Each level of constructed wetland includes a water inlet area 7, a reaction area and a water outlet area 8. The bottom of the aeration pool is provided with a microporous aerator. The microporous aerator is connected with the blower through...

Embodiment 3

[0055] The multi-level constructed wetland system for treating heavy metal wastewater in this embodiment includes algae ponds, aeration ponds and multi-level constructed wetlands. The multi-level constructed wetlands at least include the first-level constructed wetland and the last-level constructed wetland. The waste water flows through algae ponds and multi-stage constructed wetlands in turn, and the effluent flowing through the last stage of constructed wetlands is recycled to the aeration pool for enhanced oxygen supply, and then flows through the first stage of constructed wetlands until it reaches the standard discharge. The multi-stage constructed wetlands Each level of constructed wetland includes the multi-level constructed wetland. Each level of constructed wetland includes a water inlet area 7, a reaction area and a water outlet area 8. The bottom of the aeration pool is provided with a microporous aerator. The microporous aerator is connected with the blower through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com