Surface quality improving method for DLP photocureable additive manufacturing

A technology of additive manufacturing and surface quality, applied in the field of additive manufacturing, can solve the problems of low surface quality, achieve the effect of improving surface quality, scientific and reliable principles, and reducing subsequent processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The process of the method for improving the surface quality of DLP light-curing additive manufacturing involved in this embodiment is:

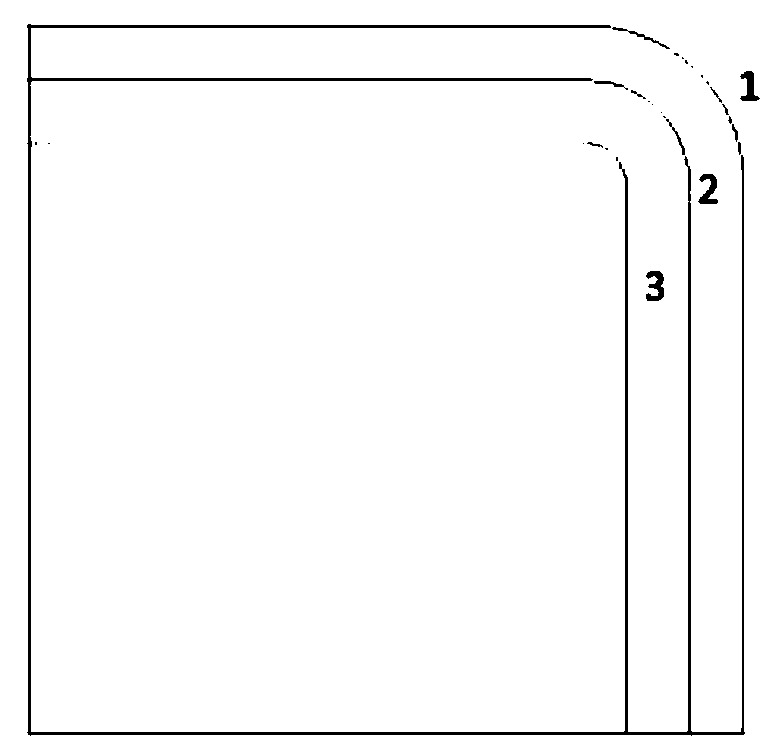

[0019] Using a computer to slice the three-dimensional digital model to obtain the outer contour 1 of the three-dimensional digital model;

[0020] Determine the beam curing width according to the DLP beam curing state;

[0021] Extend the outer contour 1 of the three-dimensional digital model to the inner normal direction and offset half the beam curing width to obtain the beam curing scanning path 2, and extend the beam curing scanning path 2 to the inner normal direction to offset half the beam curing width to obtain DLP curing internal boundary 3;

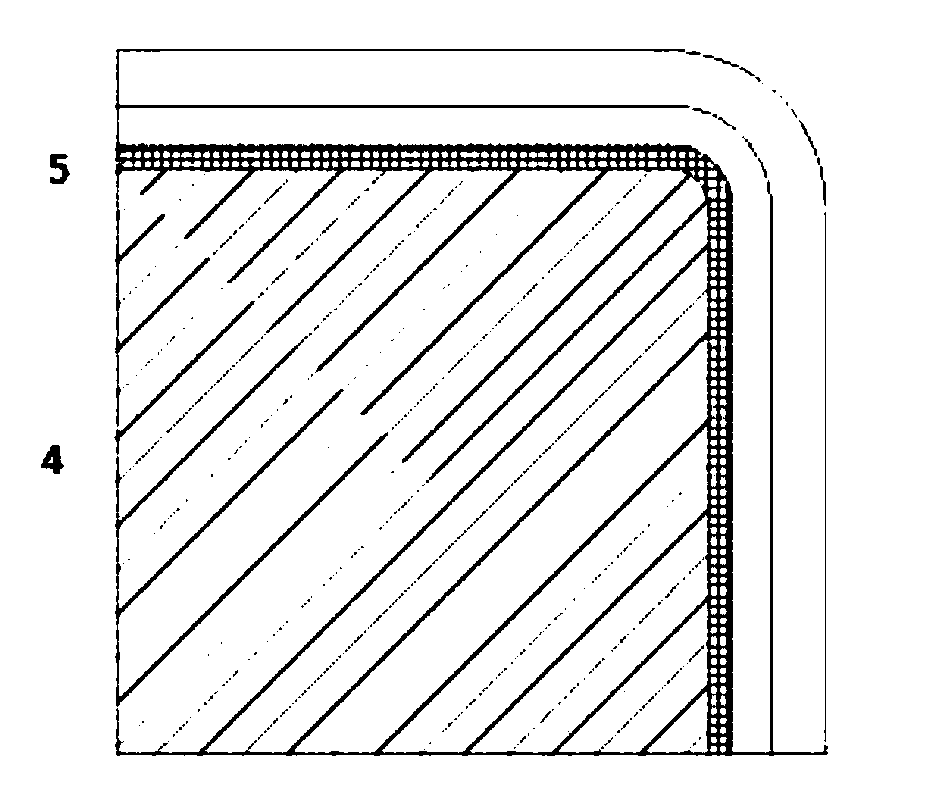

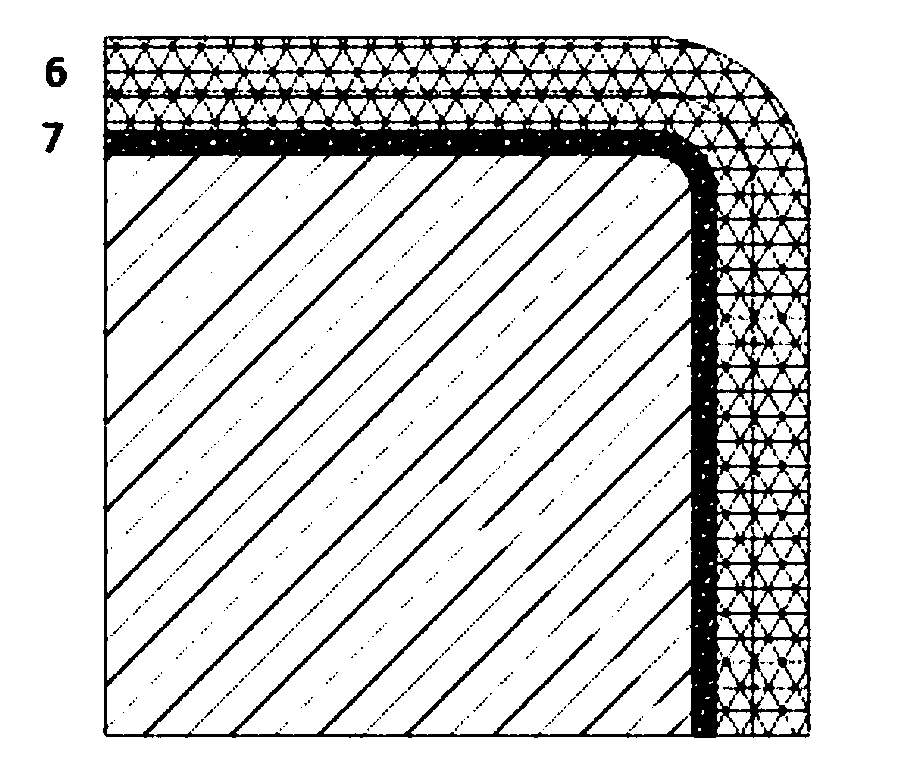

[0022] Place the three-dimensional digital model on the workbench 10, and use the DLP lamp group 8 to perform DLP curing on the inside of the DLP curing inner boundary 3 to obtain a curing area 4, and at the same time, generate DLP caused by halo spread outside the DLP curing inner bou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com