Integrated curtain wall processing equipment

A processing equipment and curtain wall technology, which is applied in the field of curtain wall integrated processing equipment, can solve the problems of extended processing time, cumbersome operation, and low production efficiency, and achieve the effects of improving performance, product quality, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

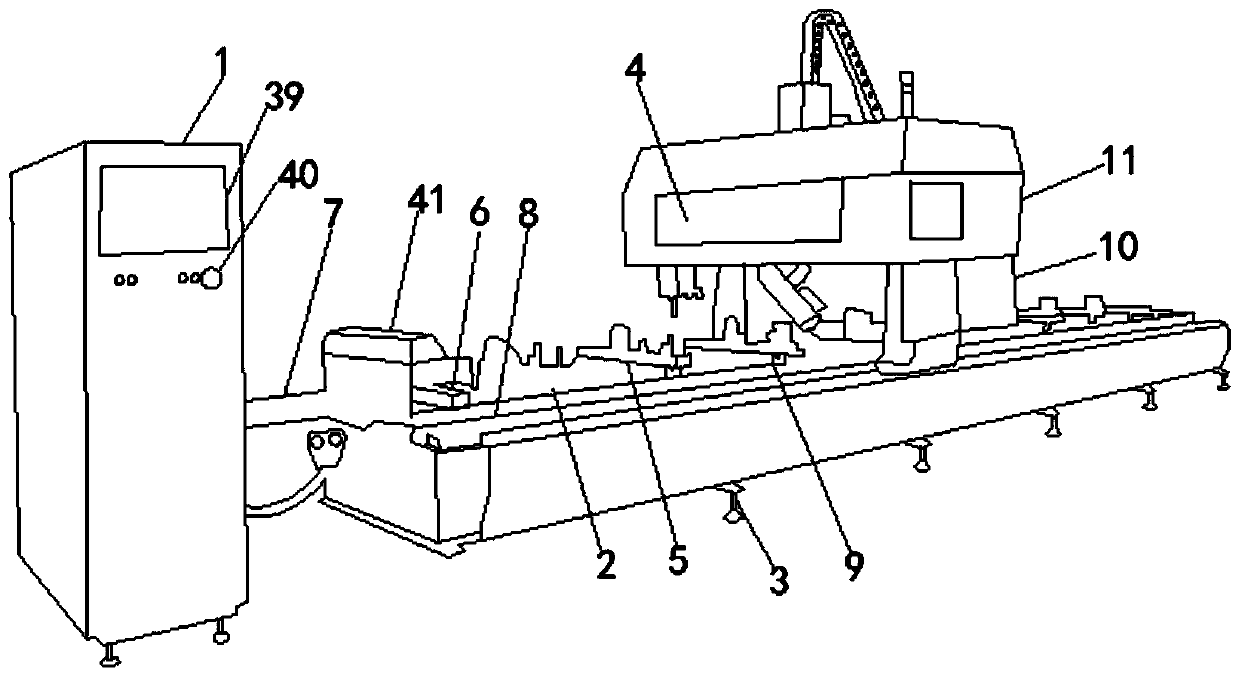

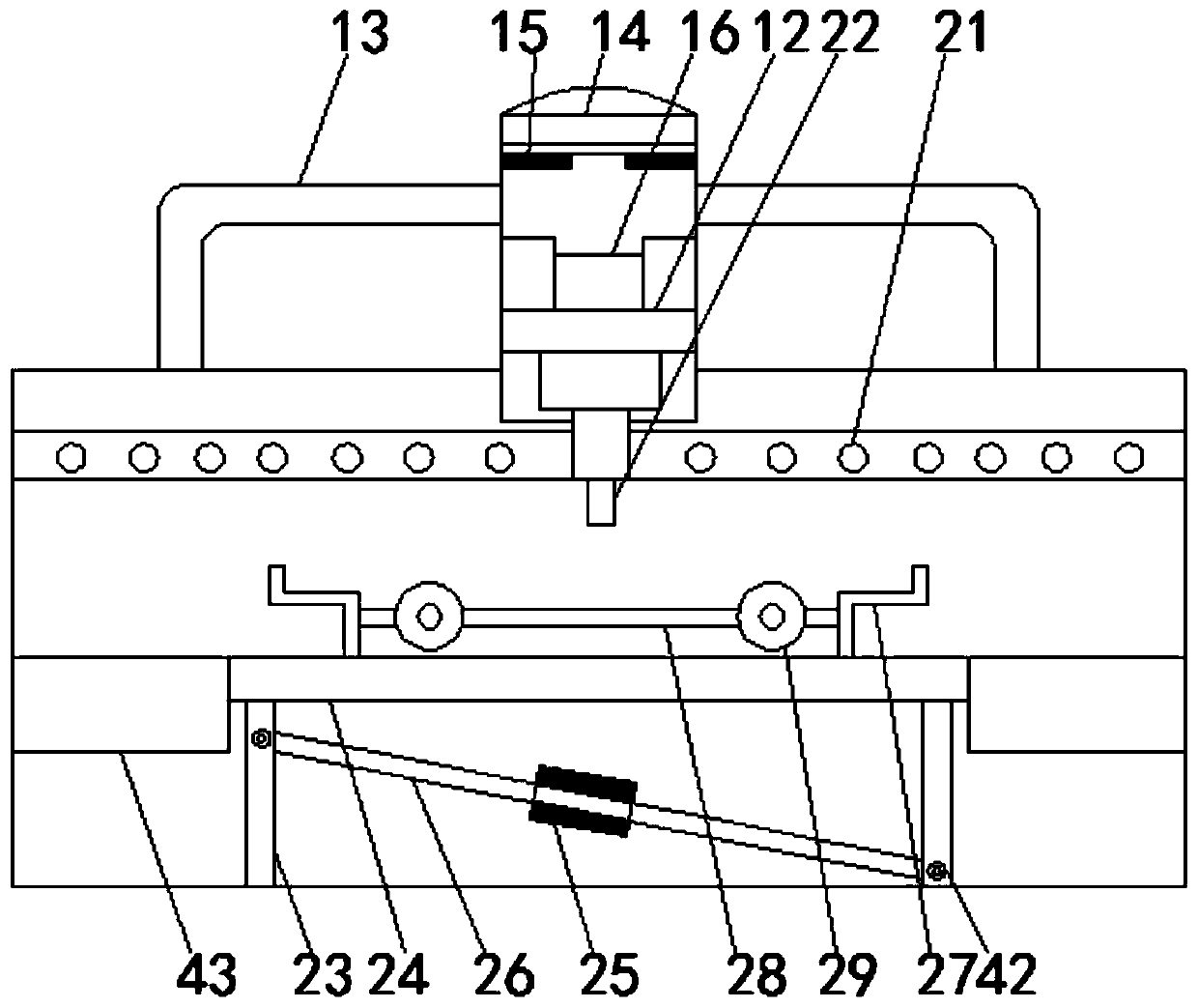

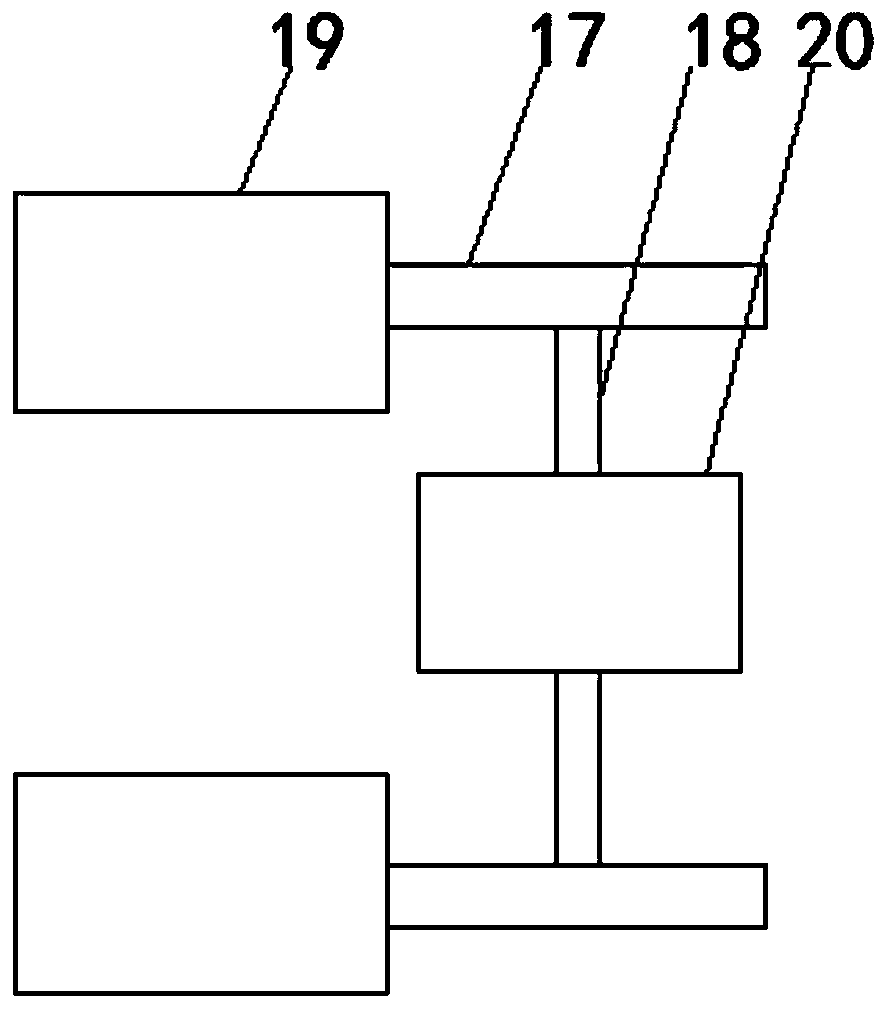

[0021] Refer to attached Figure 1-4 , an integrated curtain wall processing equipment, including a power cabinet 1, a workbench 2, a bracket 3, a machining center 4, a gantry saw 5, and a clamping part 6, and the power cabinet 1 is controlled and connected to the machining center 4 through a power line , the machining center 4 is located at the top of the workbench 2, one end of the workbench 2 is provided with the gantry saws 5 arranged equidistantly, and the bottom of the gantry saws 5 is connected to the clamping part 6 through a push rod 7 There are guide rails 8 fixedly connected between the clamping part 6 and the workbench 2, the guide rails 8 are located on both sides of the top of the workbench 2, and the top of the guide rails 8 is connected with The rotating shaft 9 of the workbench 2 is equipped with a fixing device 10 at the end far away from the gantry saw 5 .

[0022] The machining center 4 is externally placed in a cover body 11, the top center of the cover b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com