High-efficiency ultrasonic vibration feeding system for diamond micropowder screening

A diamond micropowder and ultrasonic technology, applied in the direction of sieve, conveying bulk materials, solid separation, etc., can solve the problems of wear and tear of screening equipment, low oscillation efficiency, clogging of screen holes of screening equipment, etc., to improve stability and reliability, Prevent screening efficiency and quality, use flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

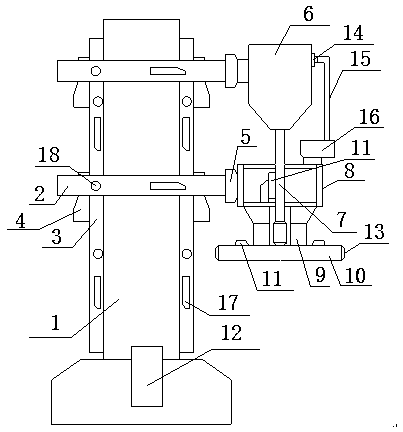

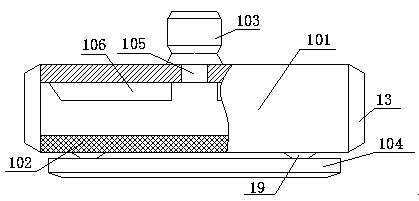

[0020] Such as figure 1 with 2 The high-efficiency diamond micropowder screening ultrasonic vibration feeding system includes a bearing column 1, a horizontal slide rail 2, a guide slide rail 3, a lifting drive mechanism 4, a walking mechanism 5, a barrel 6, a guide tube 7, and a positioning machine Frame 8, rotary drive mechanism 9, material distribution pipe 10, ultrasonic oscillation mechanism 11 and control circuit 12, bearing column 1 is a columnar structure whose axis is perpendicular to the horizontal plane, and its outer surface is evenly distributed around the axis of bearing column 1 with at least two guide slides Rail 3, each guide rail 3 is distributed parallel to the axis of the bearing column 1, and the horizontal slide rail 2 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com