Microfluidic chip with controllable tube side

A microfluidic chip and tube process technology, applied in laboratory containers, laboratory utensils, chemical instruments and methods, etc., can solve the problem of affecting experimental efficiency, difficult to control the precise reaction time of two material flows, and inconvenient reaction time. and other problems to achieve the effect of monitoring the control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

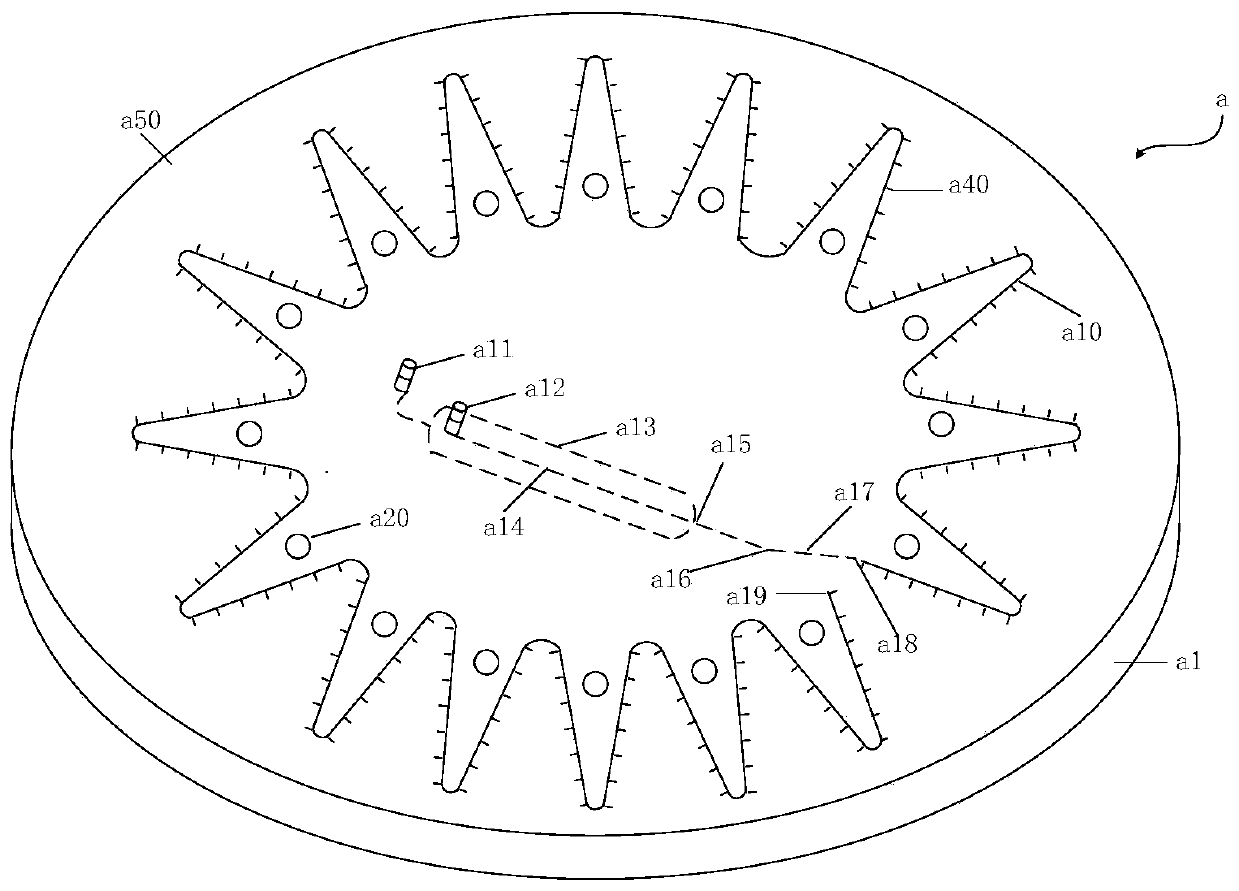

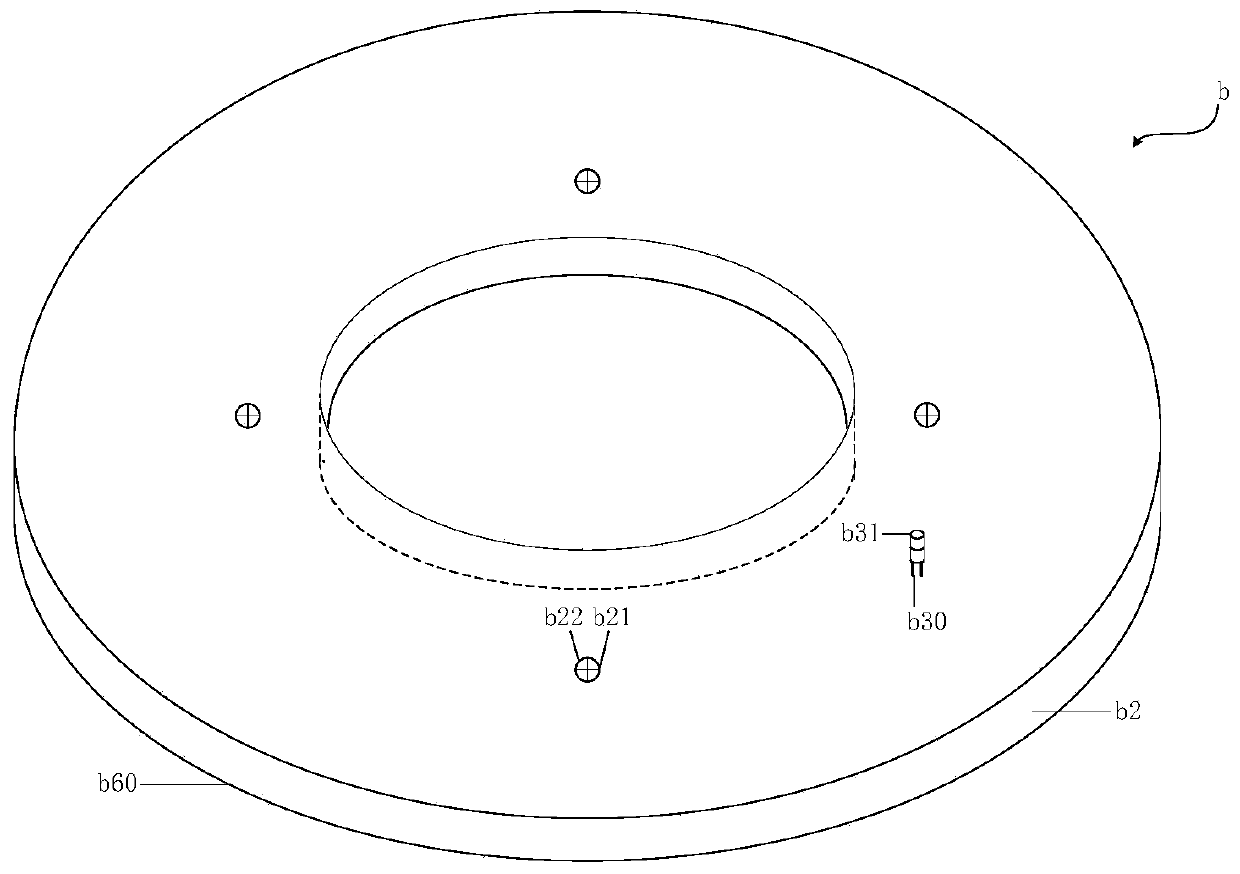

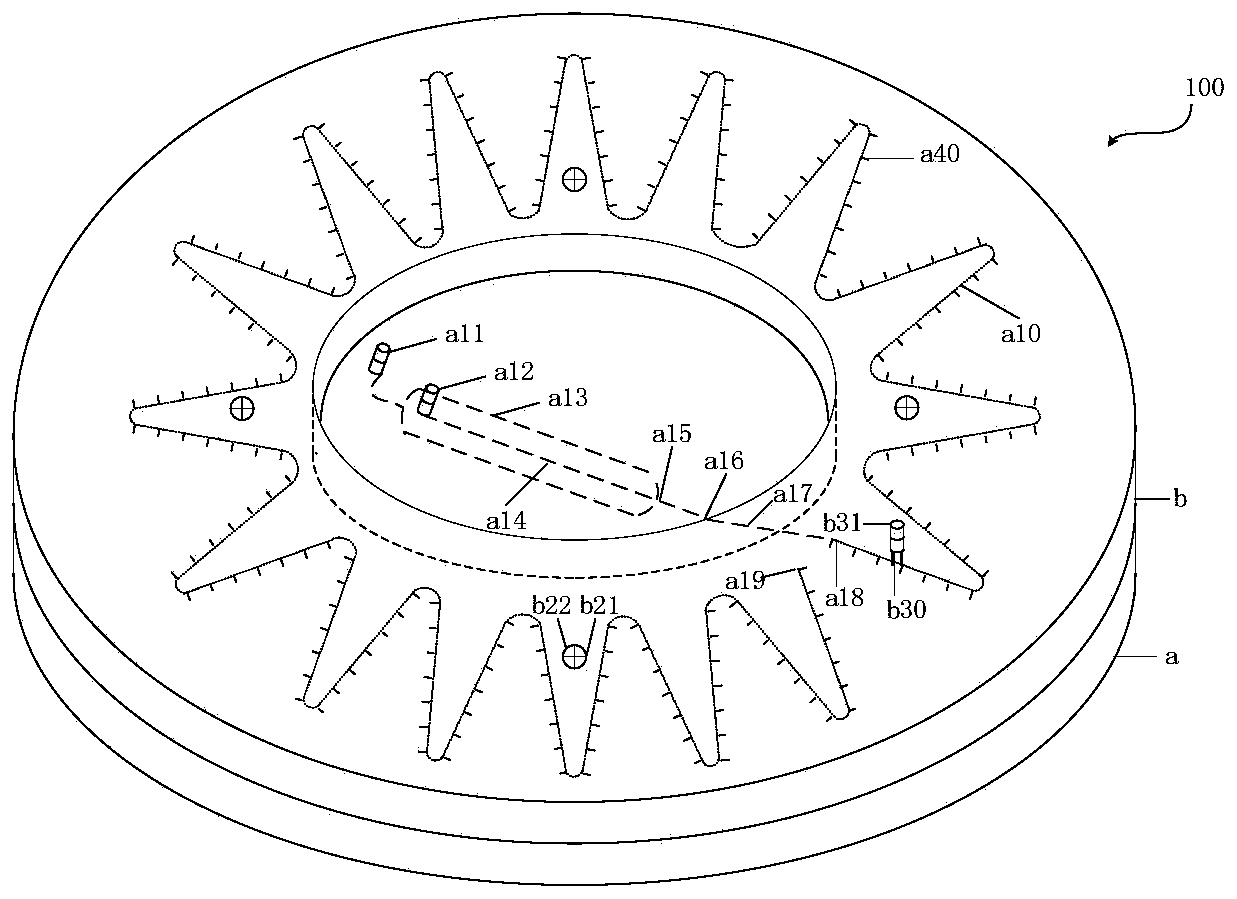

[0096] In some specific embodiments of the present invention, the micropipe grooves are a circular substrate with corrugated distribution such as figure 1 shown. figure 1 Among them, the circular substrate a in which the microtube recesses are distributed in a corrugated shape includes a substrate a1, and a microtube recess used as a closed end a19 of the microtube reactor is arranged in the annular region of the substrate a1 corresponding to the annular cover plate b Road a10, the cross-section of the micropipe groove a10 is C-shaped or rectangular with the opening upward and flush with the upper surface a50 of the base a1; At least 16 screw holes a20 are uniformly and symmetrically distributed on the circumference, and the screw holes a20 have a screw hole depth equal to 1 / 3-2 / 3 of the thickness of the substrate a1, or the screw holes a20 are through channels.

[0097] A sealing strip groove a70 is provided on both sides and ends of the micropipe groove a10, and the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com