a ti 4 o 7 / ti 3 o 5 Miscible fiber electrocatalysts and their applications in oxygen reduction

An electrocatalyst and mixed-phase technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of catalyst stability reduction, low storage, poor stability, etc., achieve high oxygen reduction catalytic activity, simple preparation method, and solve poor stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

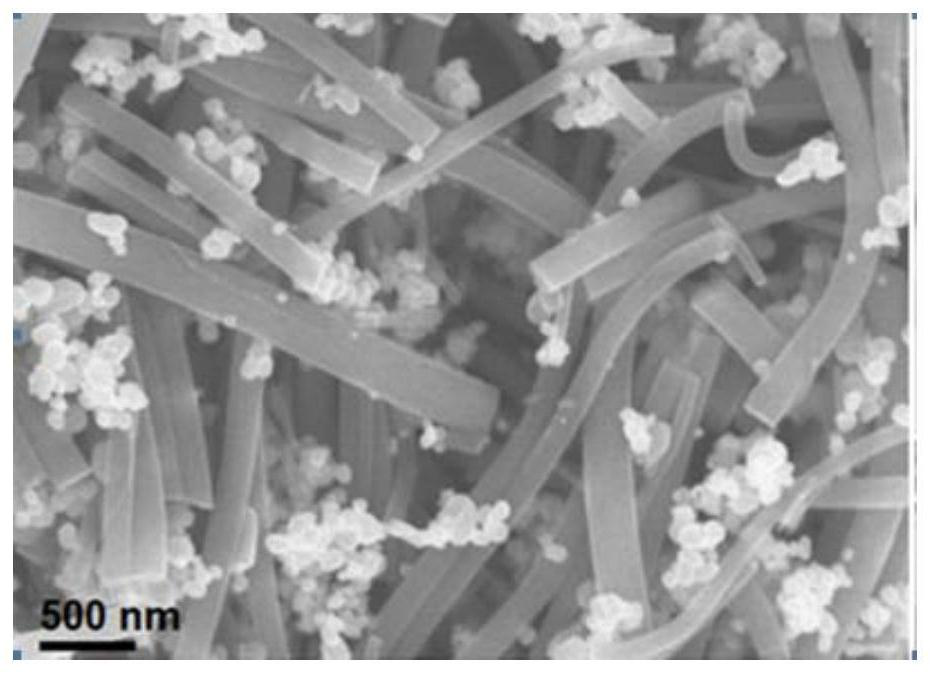

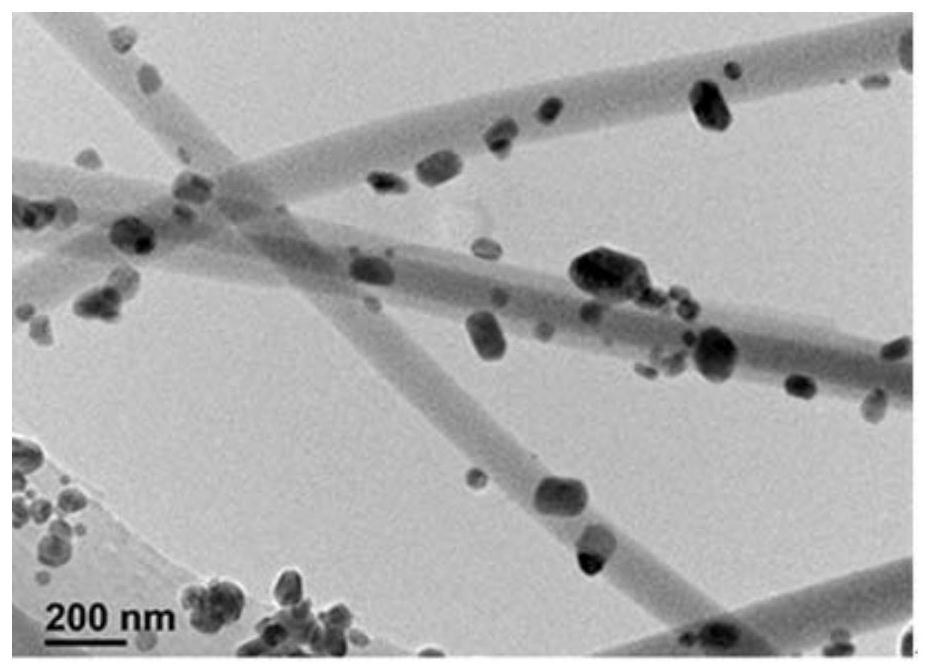

[0023] Put 0.4g of polyvinylpyrrolidone, 8mL of absolute ethanol, 2mL of acetic acid, and 2.2857g of tetrabutyl titanate in a conical flask, and stir at room temperature for 48 hours to obtain a light yellow solution, and then add 0.5g of dopamine hydrochloride to the solution, Stirring was continued at room temperature for 24 h to obtain a dark red solution. Inject the obtained dark red solution into a 5mL syringe, apply a high voltage of 12kV through the electrospinning device, and collect the fibers at a distance of 24cm from the syringe tip on the receiving plate to obtain amorphous TiO 2 nanofibrous membrane. The resulting amorphous TiO 2 The nanofibrous membrane was placed in a high-temperature tube furnace with argon gas, and the temperature was raised from room temperature to 1000 °C at a rate of 20 °C / min, and kept for 30 min to obtain Ti 4 o 7 / Ti 3 o 5 Miscible nanofibrous electrocatalysts. Such as figure 1 As shown, the phase of the prepared material is Ti ...

Embodiment 2

[0025] Put 0.8g of polyvinylpyrrolidone, 8mL of absolute ethanol, 2mL of acetic acid, and 2.2857g of tetrabutyl titanate in a conical flask, and stir at room temperature for 48 hours to obtain a light yellow solution, and then add 0.4g of dopamine hydrochloride to the solution, Stirring was continued at room temperature for 24 h to obtain a dark red solution. Inject the obtained dark red solution into a 5mL syringe, apply a high voltage of 15kV through the electrospinning device, and collect the fibers at a distance of 24cm from the tip of the syringe on the receiving plate to obtain amorphous TiO 2 nanofibrous membrane. The resulting amorphous TiO 2 The nanofibrous membrane was placed in a high-temperature tube furnace with argon, and the temperature was raised from room temperature to 1100 °C at a rate of 35 °C / min, and kept for 30 min to obtain Ti 4 o 7 / Ti 3 o 5 Miscible nanofibrous electrocatalysts. Obtained Ti 4 o 7 / Ti 3 o 5 The diameter of the miscible nanofi...

Embodiment 3

[0027]Put 0.4g of polyvinylpyrrolidone, 8mL of absolute ethanol, 2mL of acetic acid, and 2.2857g of tetrabutyl titanate in a conical flask, and stir at room temperature for 48 hours to obtain a light yellow solution, then add 1g of dopamine hydrochloride to the solution, and Stirring was continued for 24 h to obtain a dark red solution. The obtained dark red solution was injected into a 5mL syringe, and a high voltage of 15kV was applied through an electrospinning device, and the fibers were collected on the receiving plate at a distance of 24cm from the tip of the syringe to obtain amorphous TiO 2 nanofibrous membrane. The resulting amorphous TiO 2 The nanofibrous membrane was placed in a high-temperature tube furnace with argon, and the temperature was raised from room temperature to 1000 °C at a rate of 35 °C / min, and kept for 30 min to obtain Ti 4 o 7 / Ti 3 o 5 Miscible nanofibrous electrocatalysts. Obtained Ti 4 o 7 / Ti 3 o 5 The diameter of the mixed-phase nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com