High-capacity small button-type lithium battery inner casing and insulating film fixing processing method

A processing method and insulating film technology, applied to battery pack parts, circuits, electrical components, etc., can solve the problems of poor elasticity of PVC materials, high rate of defective products, small effective space of products, etc., and achieve the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

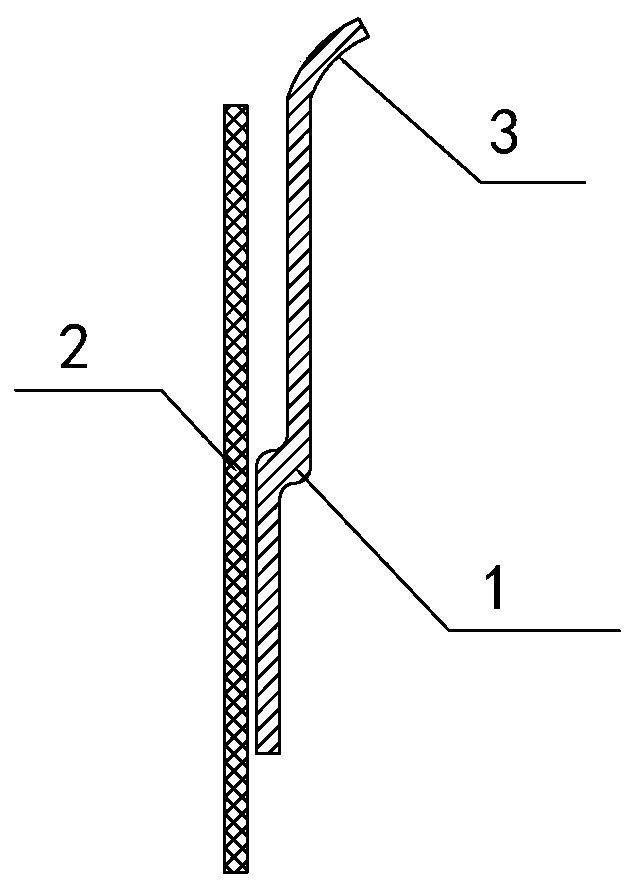

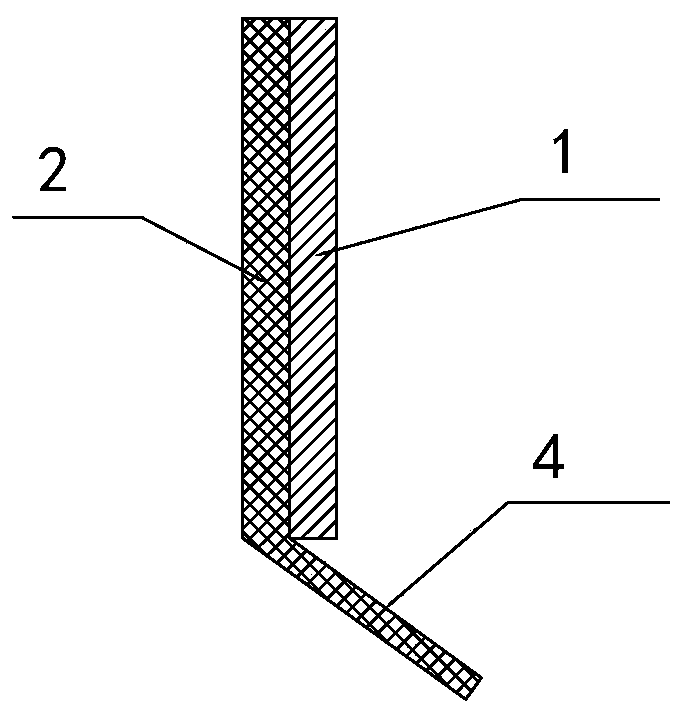

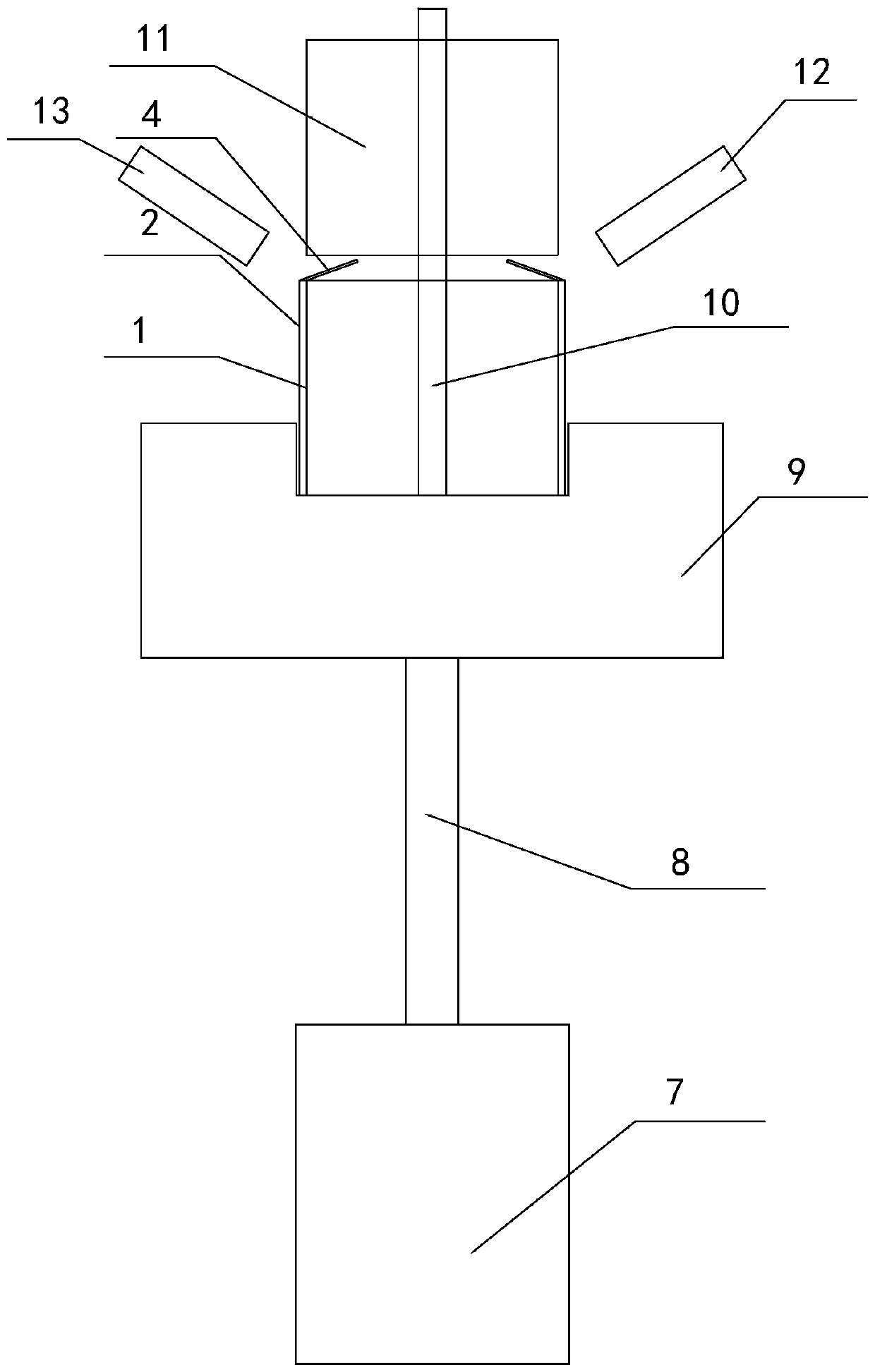

[0031] The present invention is mainly a high-capacity small button-type lithium battery inner case 1 and insulating film 2 fixing processing method, which is applied to the processing of the small button-type lithium battery inner case 1, and the purpose is to fix the lithium battery inner case 1 and the insulating film 2 together. The invention mainly includes the following steps:

[0032] (1) Material selection: In this example, PVDF (PVDF polyvinylidene fluoride) is selected, the appearance is translucent or white powder or particles, the molecular chains are closely arranged, and there are strong hydrogen bonds, and the oxygen index is 46%. , non-combustible, crystallinity 65%~78%, density 1.77~1.80g / cm3, melting point 172°C, heat distortion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com