An improved structure suitable for superjunction dmos devices

An improved structure and device technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as body diode reverse recovery is too hard, IRM and Qrr increase, prone to failure, etc., to increase the softness factor and slow down the current Decrease slope, improve the effect of reverse recovery curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

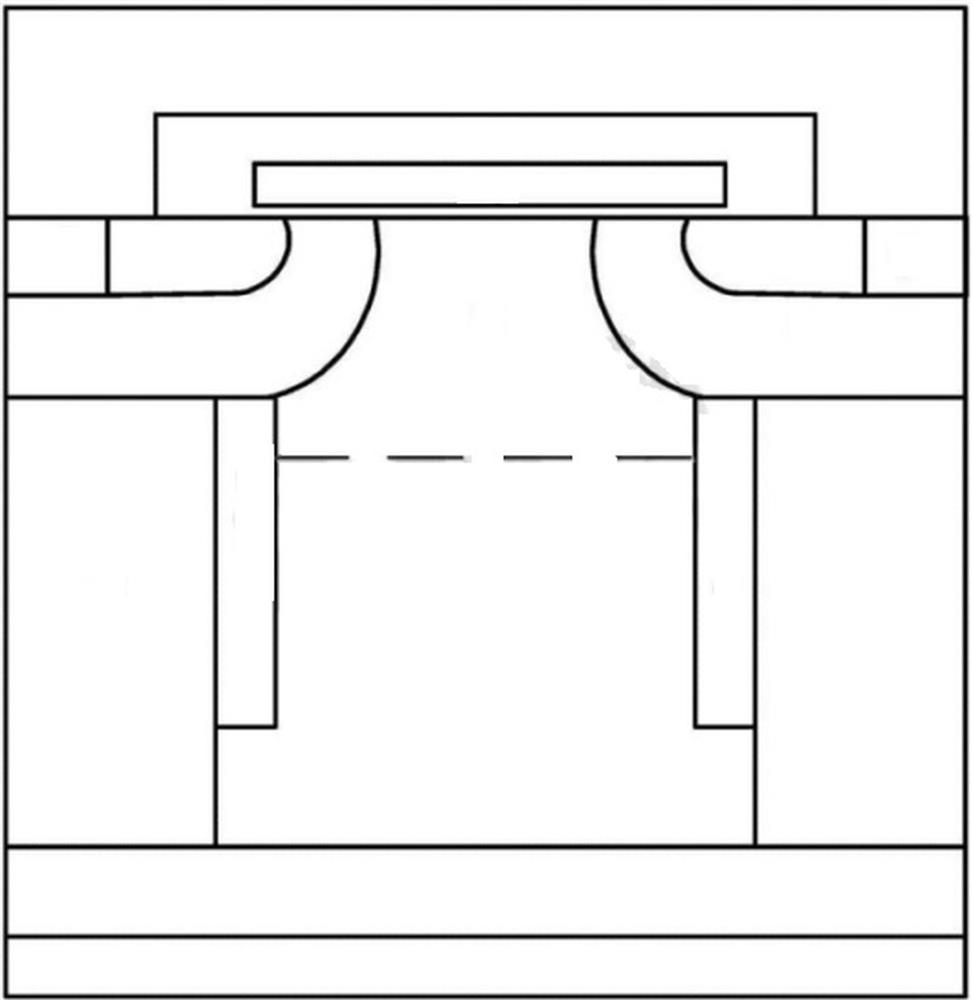

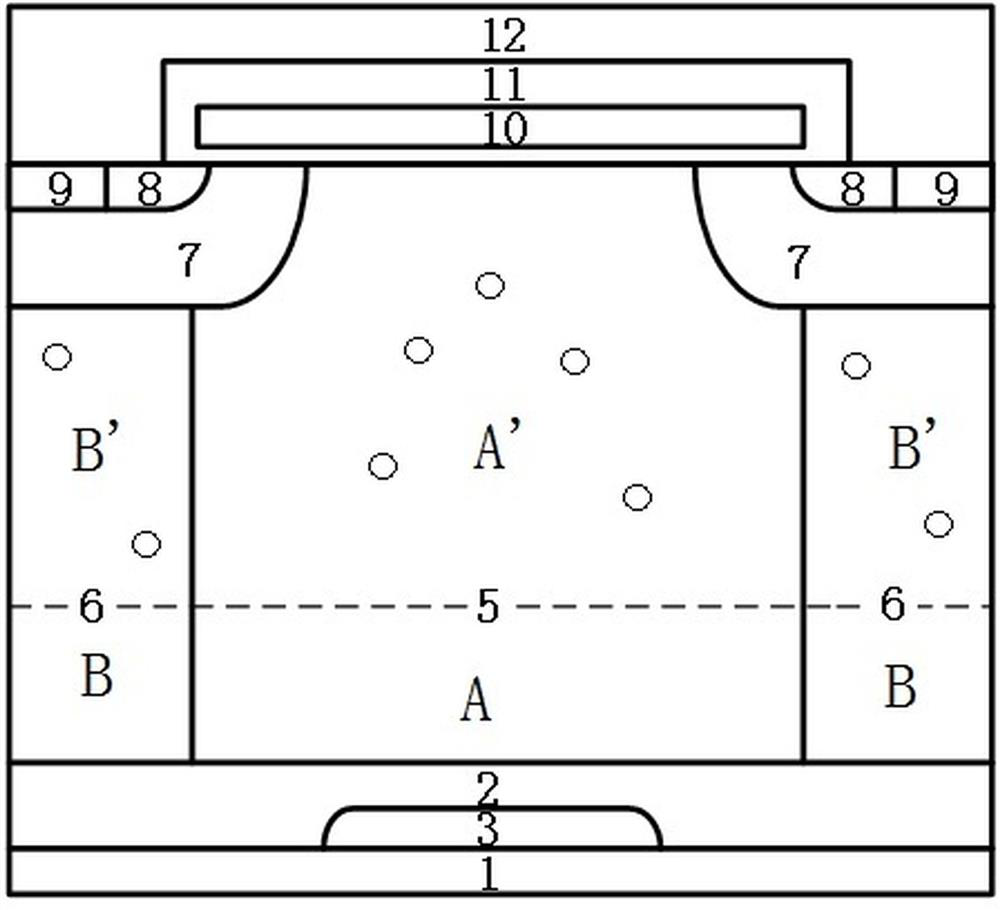

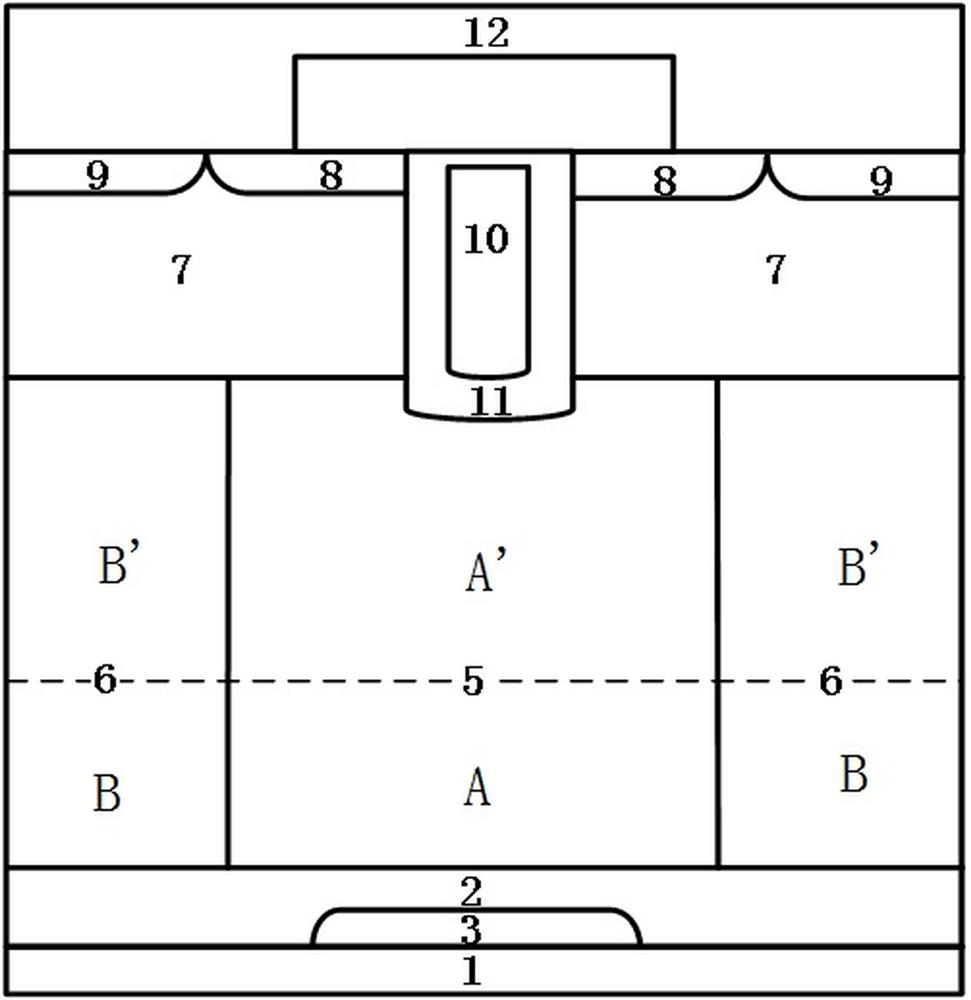

[0021] As a most basic embodiment of the present invention, such as figure 2 , this embodiment discloses an improved structure suitable for superjunction DMOS devices. A heavily doped semiconductor is also provided on the contact surface between the first conductive type semiconductor doped substrate 2 of the superjunction DMOS device and the metallized drain. The second conductivity type semiconductor island region 3, the heavily doped second conductivity type semiconductor island region 3 constitutes a hole injection region at the bottom of the device, and the heavily doped second conductivity type semiconductor island region 3 is embedded in the first The conductive type semiconductor doped substrate 2 and its bottom are also in contact with the upper surface of the metallized drain; and the first conductive type doped pillar region 5 and the second conductive type semiconductor doped pillar region 6 The carrier lifetimes are all longer than those in the upper half region....

Embodiment 2

[0024] As a preferred embodiment of the present invention, such as figure 2 , this embodiment discloses an improved structure suitable for superjunction DMOS devices. A heavily doped semiconductor is also provided on the contact surface between the first conductive type semiconductor doped substrate 2 of the superjunction DMOS device and the metallized drain. The second conductivity type semiconductor island region 3, the heavily doped second conductivity type semiconductor island region 3 constitutes a hole injection region at the bottom of the device, and the heavily doped second conductivity type semiconductor island region 3 is embedded in the first The conductive type semiconductor doped substrate 2 and its bottom are also in contact with the upper surface of the metallized drain; and the first conductive type doped pillar region 5 and the second conductive type semiconductor doped pillar region 6 The carrier lifetimes are all longer than those in the upper half region. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com