Memory and method of forming the same

A memory and storage area technology, applied in semiconductor devices, electric solid state devices, electrical components, etc., can solve the problems of low production efficiency and complex process, and achieve the effect of simplifying and reducing the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] As mentioned in the background, prior art memories have poor performance.

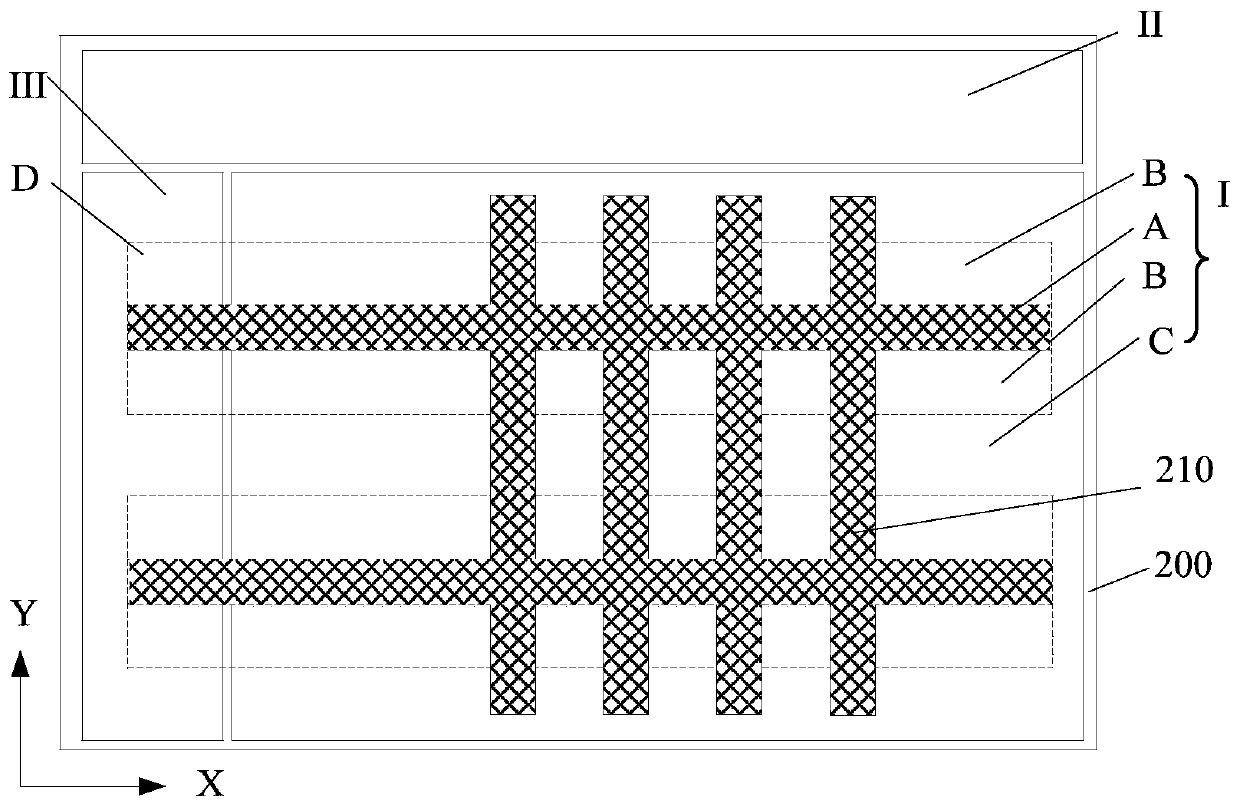

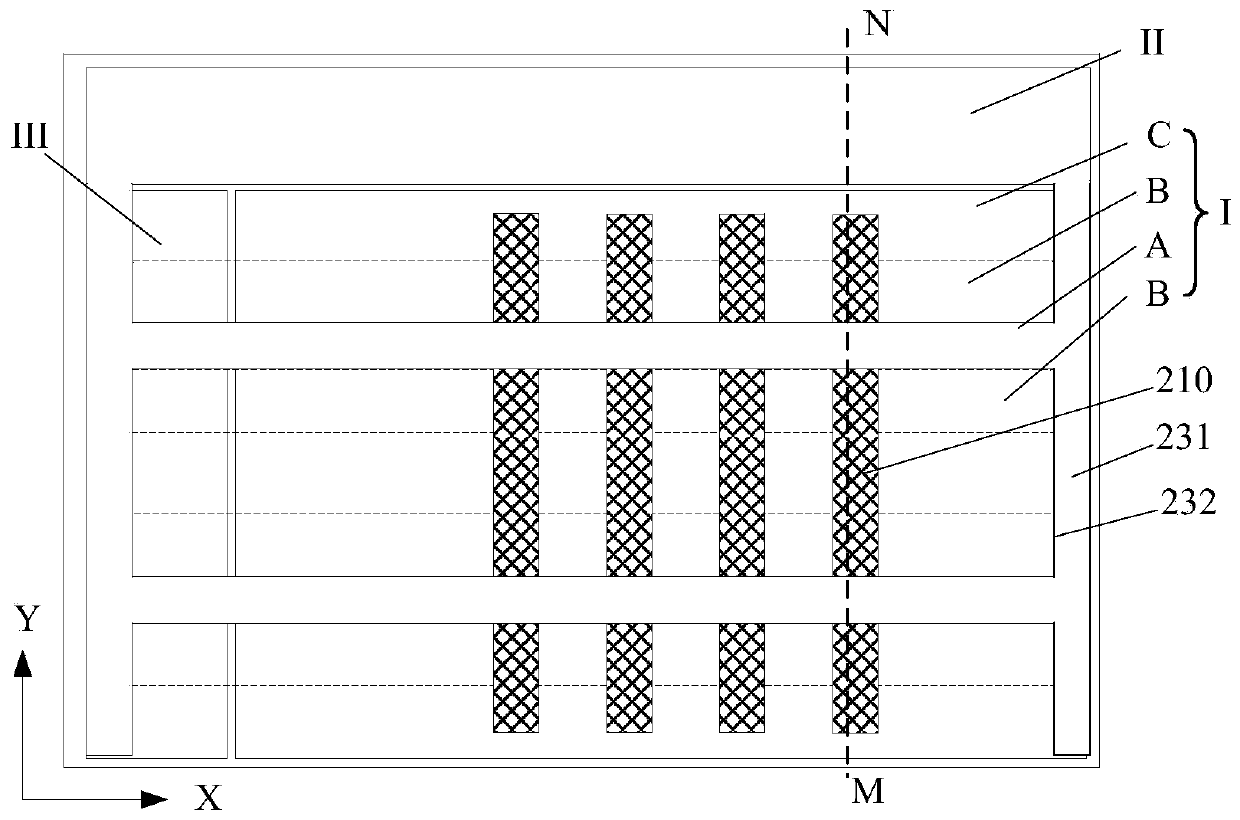

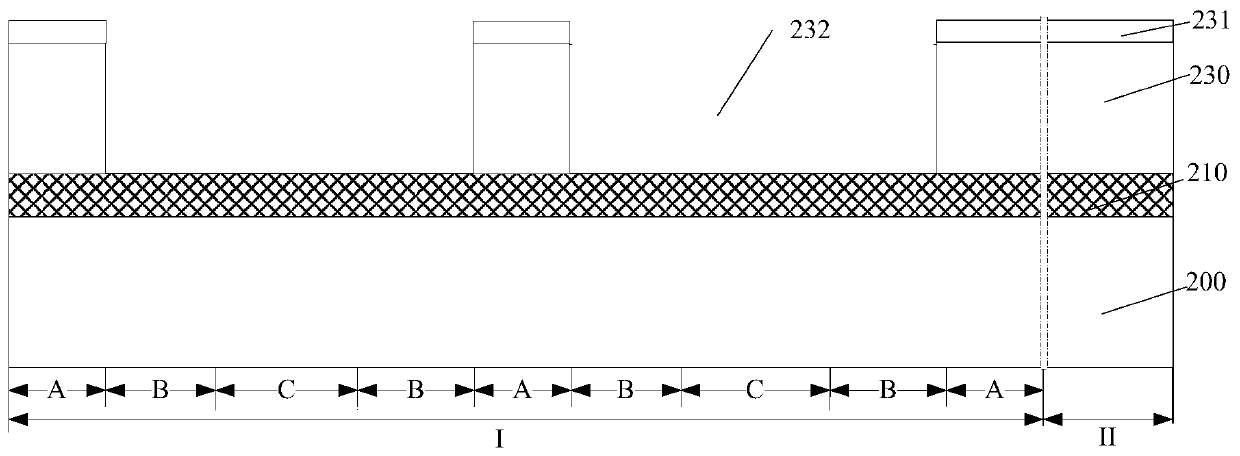

[0028] A memory, comprising: a substrate, the substrate includes an erasing area and a floating gate area, the floating gate area is adjacent to the erasing area and located on both sides of the erasing area; In addition to the gate structure; the floating gate structure respectively located on the floating gate region of the substrate; the first side wall, the second side wall and the control gate structure located on the floating gate structure, the second side wall is located on the control gate structure On the gate structure, the first sidewall is parallel to the second sidewall and the control gate structure.

[0029] In the formation process of the above-mentioned memory, one mask is required to form the erasing gate structure, the control gate structure and the floating gate structure, so at least three patterning processes are required. When continuing to form the word line structure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com