Online monitoring system for oil seal leakage of mining reducer and online monitoring method

A technology of monitoring system and reducer, which is applied in the direction of measuring the increase and decrease rate of the fluid, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of not easy to judge oil stains, increase maintenance costs, poor conditions, etc., to achieve Reduce the probability of reducer oil leakage failure, reduce inspection and maintenance costs, and reduce the effect of inspection and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions and beneficial effects adopted in the embodiments of the present invention will be further explained and described in detail below in conjunction with the accompanying drawings of the present invention.

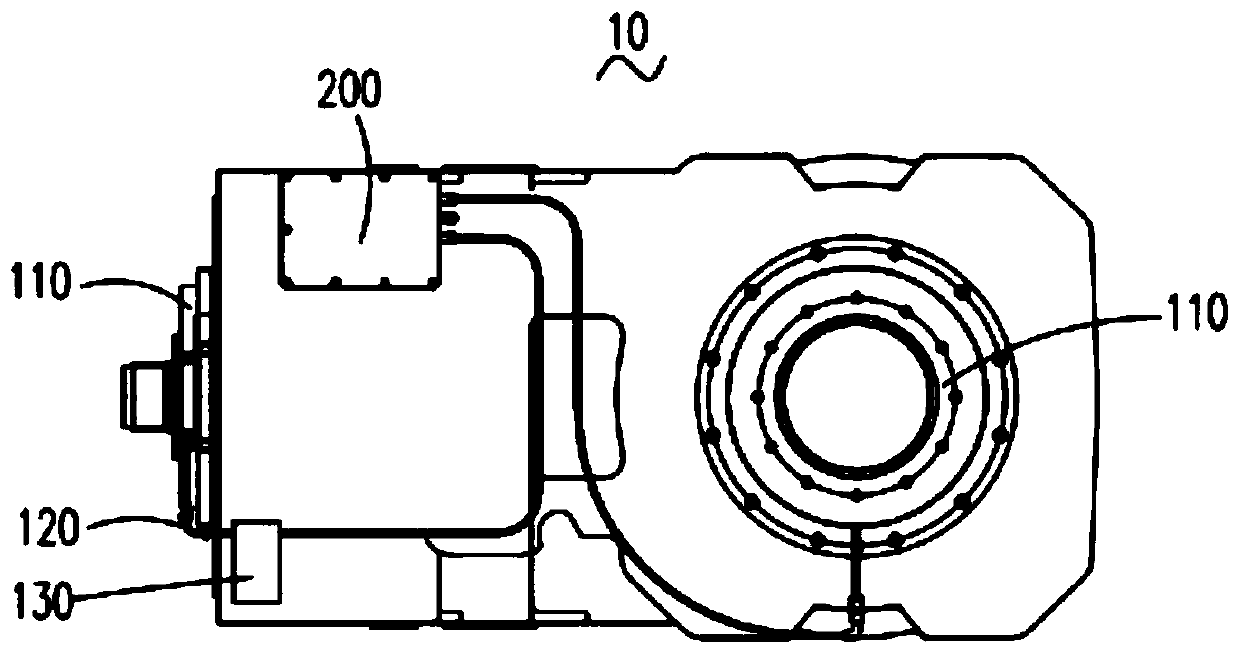

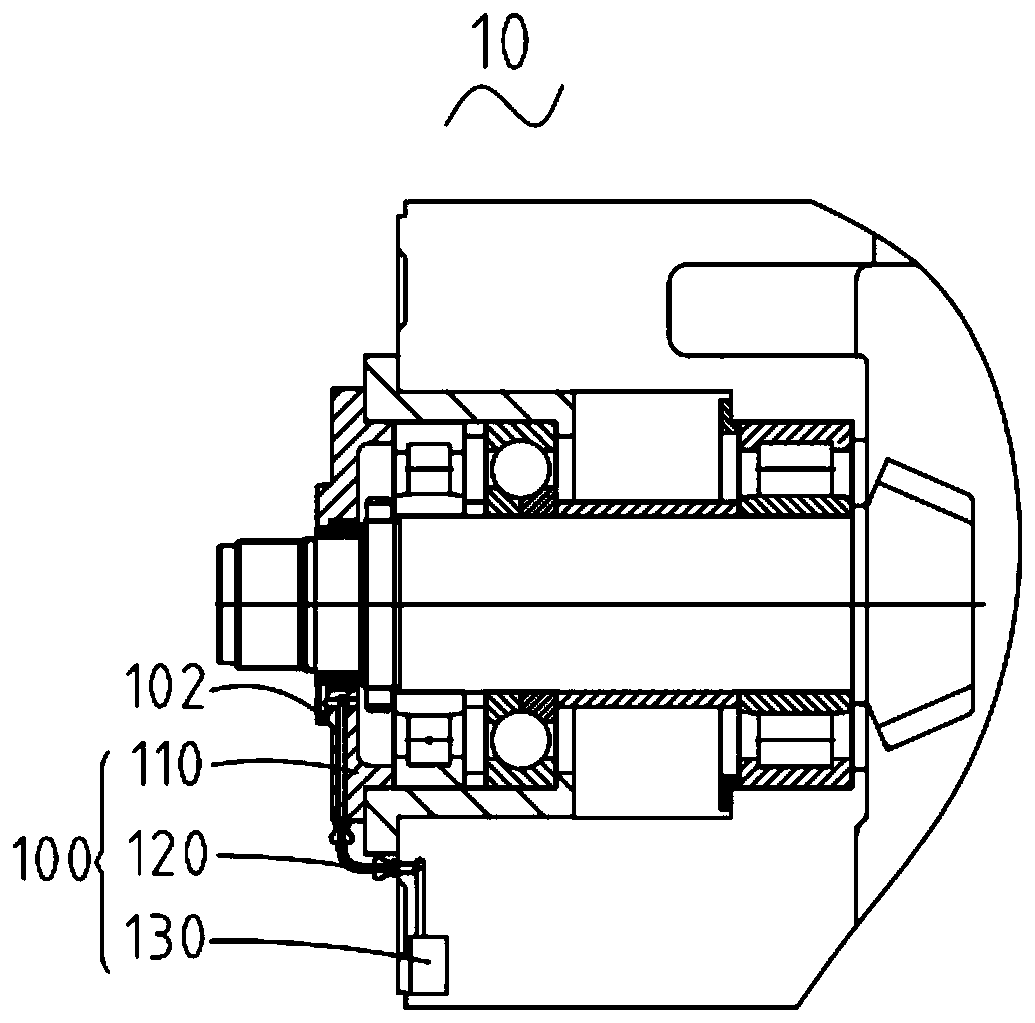

[0034] Please see Figure 1 to Figure 6 , the embodiment of the present invention provides an online monitoring system 10 for mine reducer oil seal leakage, which is used to realize the remote monitoring of the oil leakage fault of the mine reducer, timely and accurately find the oil leakage of the reducer, and scientifically judge the fault of the reducer Maintenance time point, reduce maintenance costs. The mine reducer oil seal leakage online monitoring system 10 includes an oil collection device 100, a detection device 200 and a central controller 300, the oil collection device 100 is used to collect the seal oil leaked from the reducer, and the detection device 200 is connected to The oil collecting device 100 is used to detect and output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com