Low temperature pipeline system

A pipeline system and pipeline technology, used in pipeline protection, pipeline heating/cooling, and pipeline protection through thermal insulation, etc., can solve problems such as safety accidents and waste of resources, and achieve high safety, cost savings, and rapid heat exchange. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] In order to reduce the consumption of pre-cooling medium in cryogenic liquid transportation pipelines and improve the discharge safety of pre-cooling medium, the present invention provides a low-temperature pipeline system with a system design pressure of 33MPa, a maximum working pressure of 30MPa, and a nominal diameter of DN150. Problems such as heat conduction and cold and heat compensation of medium transportation. The low-temperature pipeline system of the present invention is used for a wind tunnel heater test, the test medium is liquid oxygen, and the precooling medium is liquid nitrogen.

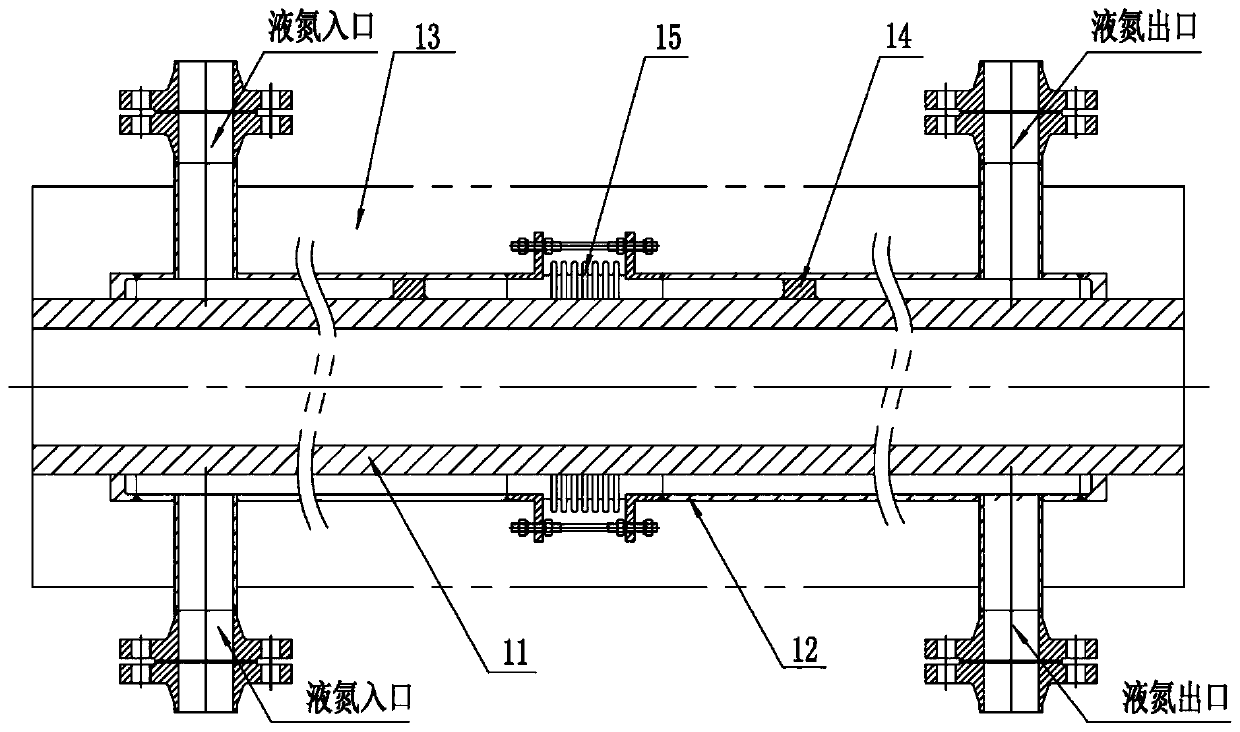

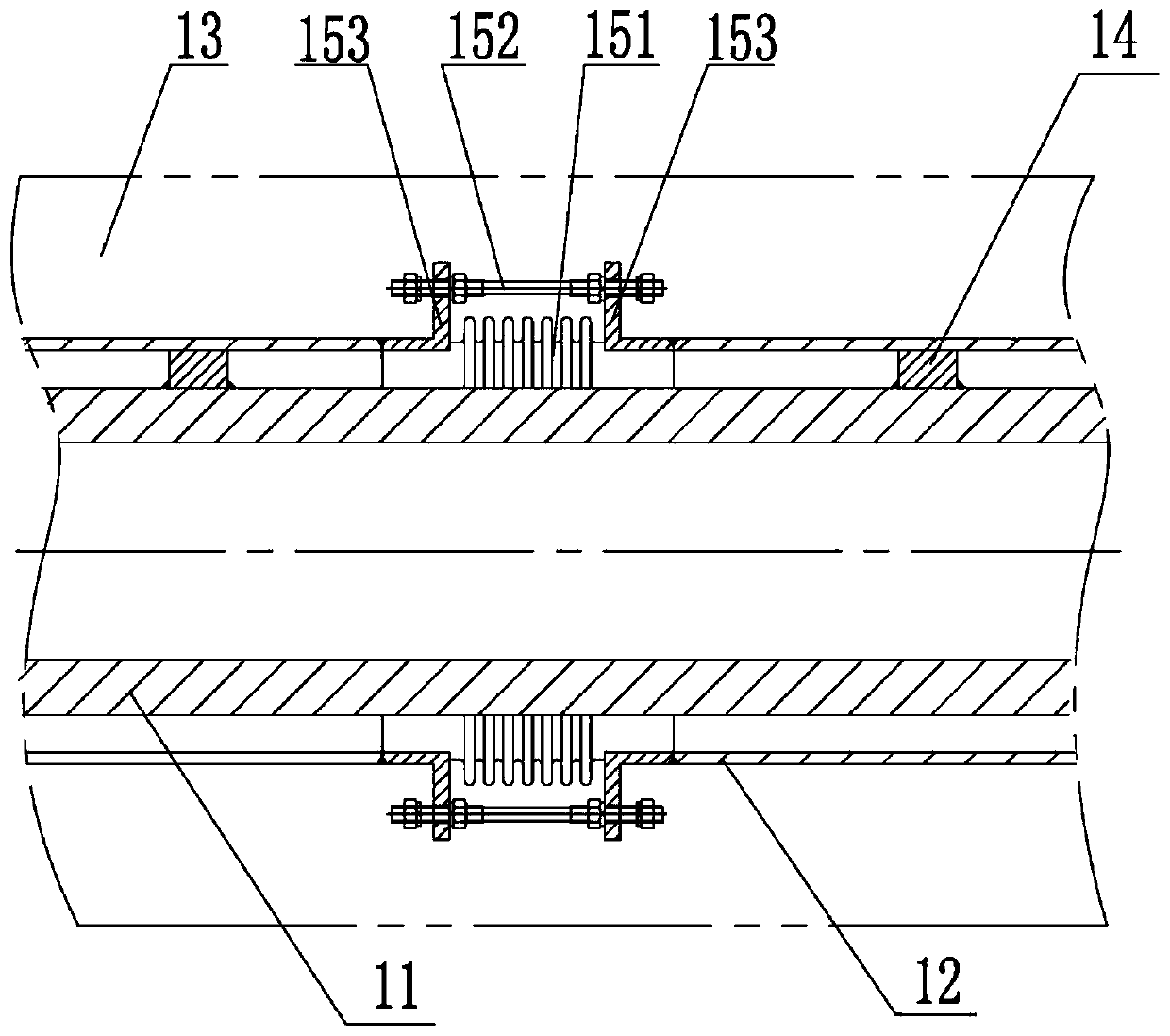

[0036] Such as figure 1 Shown, a kind of cryogenic pipeline system comprises high-pressure interlayer pipeline unit and high-pressure vacuum pipeline 3; The valve 4, the flowmeter 5 and the filter 6 on the high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com