A kind of method for extracting papermaking fibers from distiller's grains

A technology of distiller's grains and fibers, applied in papermaking, textile and papermaking, fiber raw material processing, etc., can solve the problems of high organic content, extraction of papermaking fibers, environmental pollution, etc., achieve high purity, reduce papermaking production costs, and reduce environmental pollution. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Preparation of distiller's grain fiber extract for papermaking

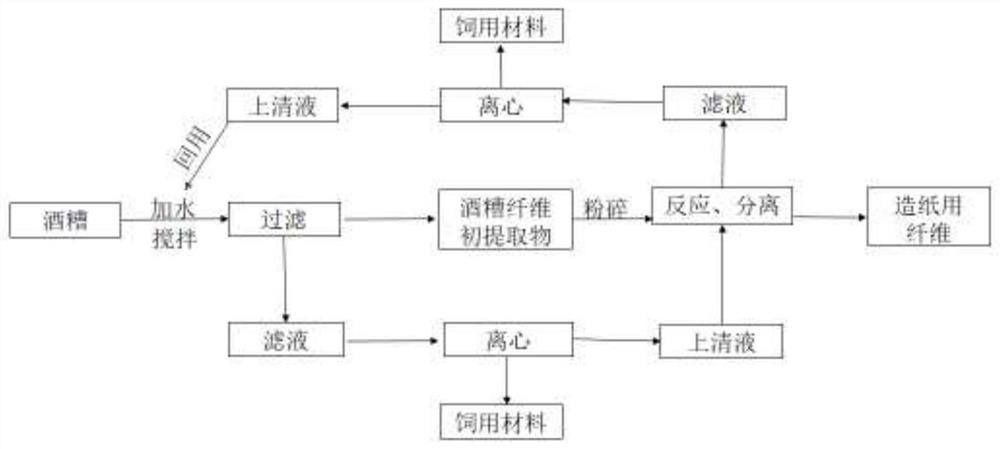

[0033] The distiller's grains used in this example come from a large Maotai-flavor liquor production enterprise. Experimental steps reference figure 1 conduct. The specific implementation steps include:

[0034] 100kg of this sauce-flavored distiller's grains (50% solid content) is added to 500kg of water, fully stirred, and a 10-mesh sieve is selected to filter the distiller's grains to remove organic components such as protein, fat, and remaining starch in the distiller's grains. The upper layer of the sieve obtained 50 kg of wet (20% solid content) distiller's grain fiber primary extract. The material of this just extract mainly comprises compositions such as cellulose, hemicellulose, lignin; The lower floor filtrate after filtering is 550kg altogether, and through centrifugation, 170kg (solid content rate 23%) of large particle component is separated, obtains supernatant 380kg. Mix t...

Embodiment 2

[0036] The distiller's grains used in this example come from a large Luzhou-flavor liquor production enterprise. Experimental steps reference figure 1 conduct. The specific implementation steps include:

[0037]Add 100kg of this Luzhou-flavor distiller's grains (solid content 36%) to 500kg of water, fully stir, select a 10-mesh sieve to filter the distiller's grains, and remove organic components such as protein, fat, and remaining starch in the distiller's grains. The upper layer just obtains 100kg of wet (solid content 20%) distiller's grain fiber primary extract. The material of this initial extract mainly comprises compositions such as cellulose, hemicellulose, lignin; The lower floor filtrate after filtering is 500kg altogether, and through centrifugation, 70kg (solid content rate 23%) of large particle component is separated, obtains supernatant 430kg. Mix the 100kg wet distiller's grain fiber primary extract with the supernatant of the filtrate, grind it finely to 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com